Direct acting relay with double bridge structure

一种直动式、继电器的技术,应用在继电器、电磁继电器、电磁继电器详细信息等方向,能够解决增加成本等问题,达到消耗降低、降低闭合温度、提高寿命的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

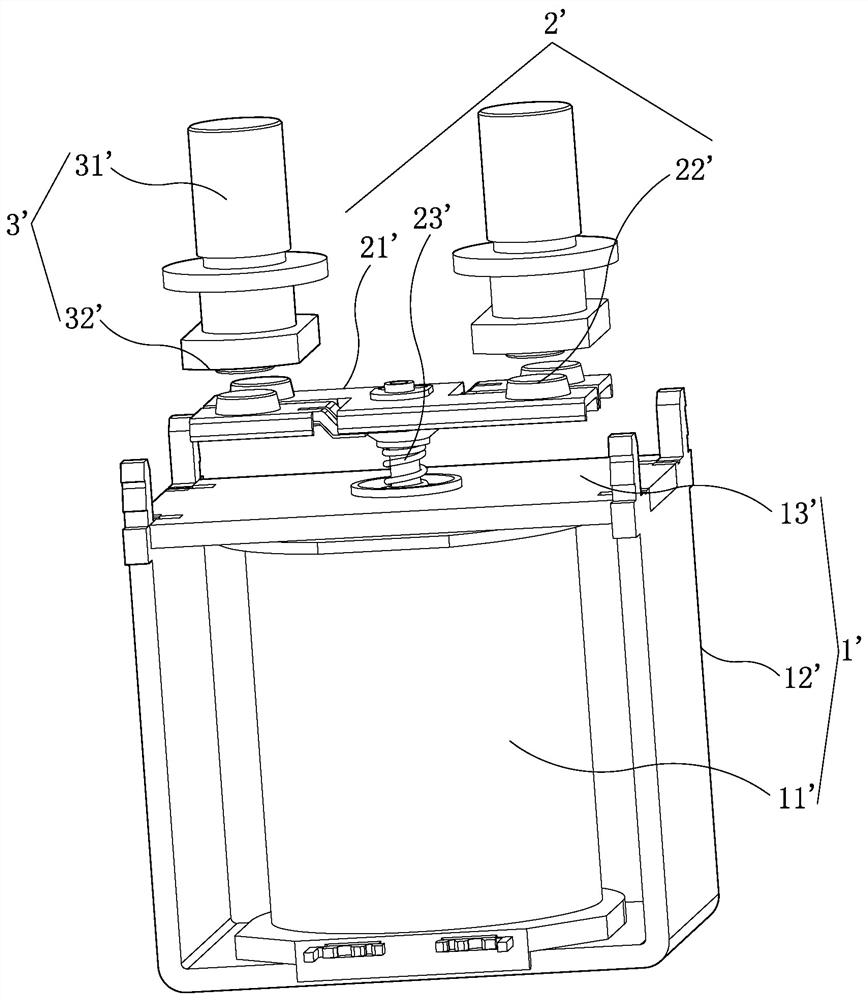

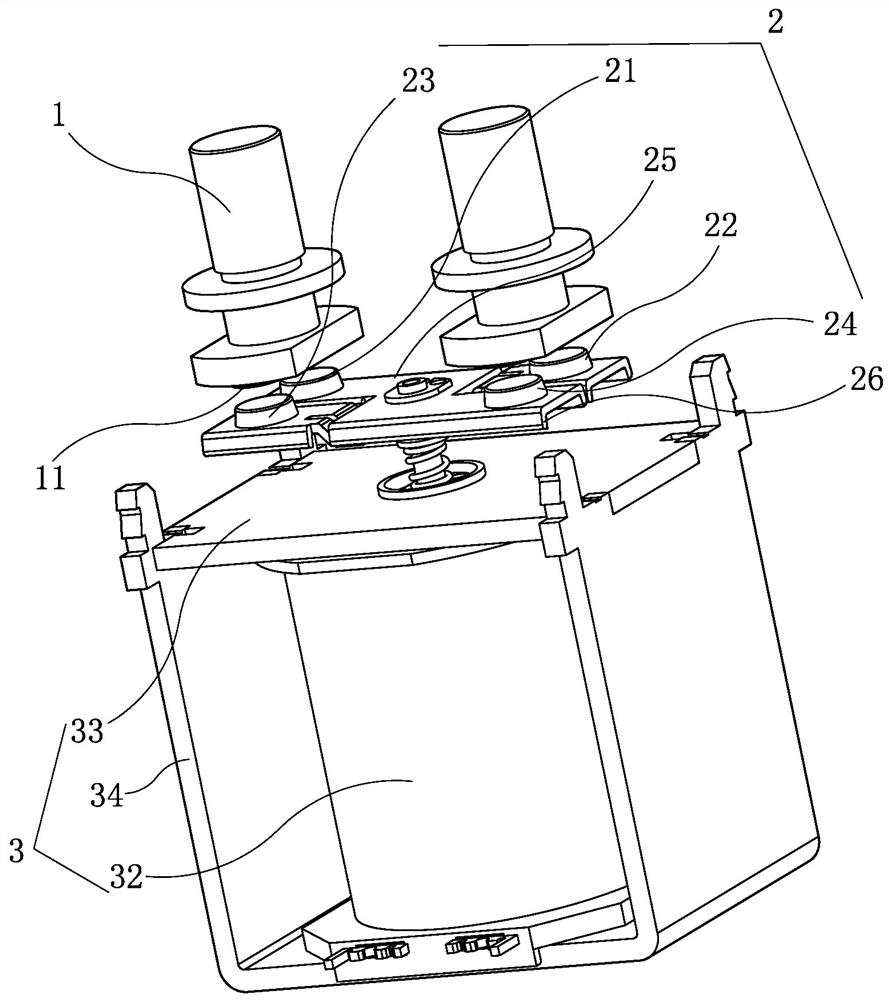

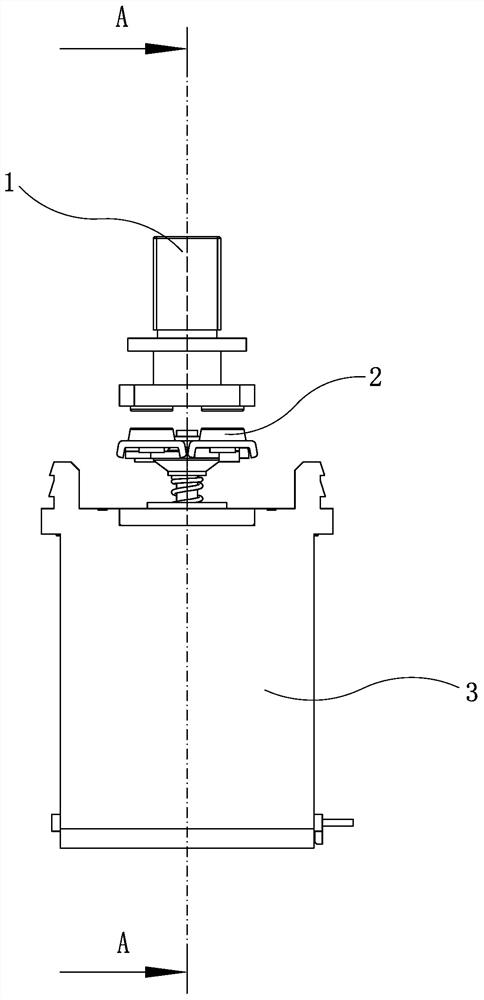

[0023] like Figure 1-Figure 4 As shown, the present invention is a direct-acting relay with a double bridge structure, including a terminal assembly 1 , a bridge assembly 2 , and a magnetic circuit assembly 3 .

[0024] The terminal assembly 1 is located above and opposite to the bridge assembly 2, and the lower part of the bridge assembly 2 is movably sleeved in the magnetic circuit assembly 3 and can move up and down.

[0025] The magnetic circuit assembly 3 includes a static iron core 31 , a coil assembly 32 , a flat yoke 33 , a U yoke 34 , and a moving iron core 35 . The moving iron core 35 is movably sleeved in the middle hole of the static iron core 31 .

[0026] like Figure 4-Figure 6 As shown, the bridge assembly 2 includes four movable contacts 21 , 22 , 23 , 24 , an upper bridge 25 , a lower bridge 26 , a bridge rod 27 , and a bridge spring 28 . The upper bridges 25 and the lower bridges 26 are both zigzag in shape, and the upper bridges 25 and the lower bridges...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com