Vertical-parting casting section die

A vertical parting and casting section technology, applied in the direction of mold, core, mold composition, etc., can solve the problem of insufficient feeding, perfect, similar to bottle mouth blockage, it is difficult to form the same cavity at one time, and the metal mold cannot be interchanged at will and other issues to achieve the effects of improving productivity and economic benefits, scientific condensation and feeding control design, and improving dynamics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

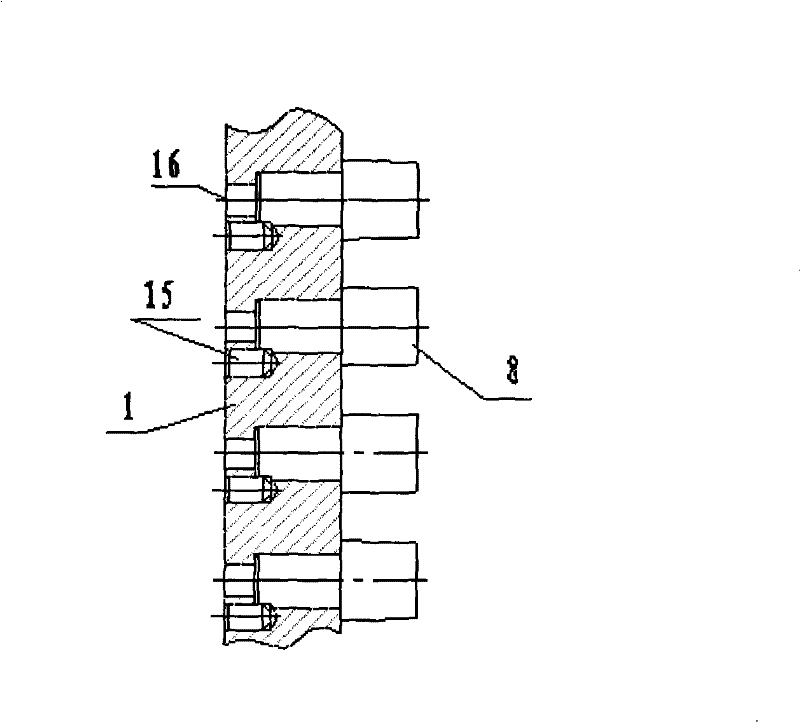

[0048] The pouring riser 2 of the present invention descends from the opening position to the channel entering the pouring riser diversion area 5, forming a bend, so that the part connecting the pouring riser 2 and the pouring riser diversion area 5 is an inclined channel .

[0049] The above structure ensures that after setting the ventilation holes 9 in the distribution area of the pouring riser, there will be no interference with the pouring riser 2, and the pouring riser 2 gives way to the ventilation holes 9 in the distribution area of the pouring riser, and can slow down the flow of the liquid. Pour the impact of the lower part of the riser 2.

Embodiment 2

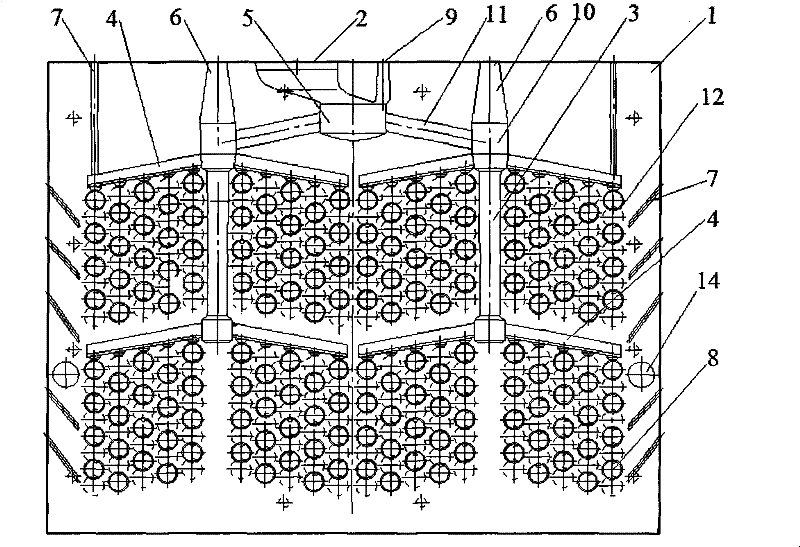

[0051] The casting section mold of the present invention is provided with a pouring riser runner 11, a main runner runner 10, a main runner 3 and a split runner 4, and the casting section model 8 is communicated with the split runner 4, so The pouring riser branch runner 11 communicates the pouring riser branch area 5 with the main runner 3 , and the main runner branch area 10 is provided at the connection position of the main runner 3 and the split runner 4 .

[0052] like figure 1 As shown in the figure, the runner is designed as the main runner 3 and the split runner 4, and the liquid metal flow is accelerated by using the principle of downward gravity.

[0053] The main runner 3 allows the liquid metal to flow downward rapidly, and the split runner 4 divides the liquid metal in the main runner 3 into the molding cavity of the casting section model 8, and the liquid metal is instantly contained in the cavity under the action of gravity. During the condensation process, the...

Embodiment 3

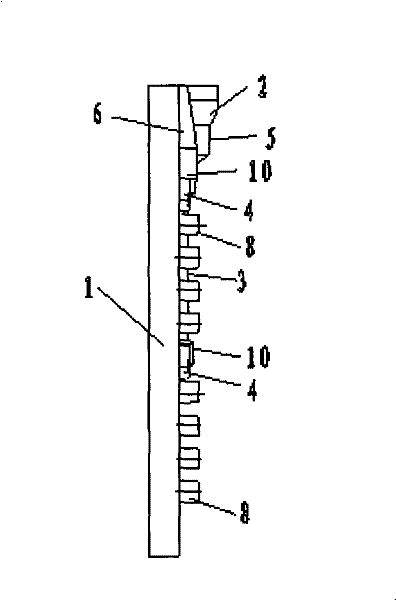

[0057] like figure 1 , figure 2 As shown, the main runner 3 of the present invention is vertically arranged, and its number is more than one; at the upper end of the main runner 3, a feeding riser 6 is provided.

[0058] The main runner 3 is set vertically downward, the split runner 4 is placed on both sides from the middle to the two sides, and the axis of the casting section model 8 is horizontal. to split runner 4. The overall arrangement is vertical downward, relatively oblique arrangement, compared with the existing vertical parting mold, the free area is small, the sand mold space is fully utilized, the space utilization rate is increased by about 8%, and the product process yield is relatively high . According to the "shape" arrangement of the casting mould provided by the invention, the cavity entity expands to the vertical direction of the parting surface, and the overall sand mold space utilization rate is increased by nearly 30 percentage points compared with th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com