Vertical-parting casting ball and casting section die

A technology of vertical parting and ball casting, which is applied in the direction of mold, core, and mold composition, etc., and can solve problems such as bottleneck blockage and the difficulty of one-time molding of the same cavity. and other problems, to achieve the effect of solving the backward situation of manual operation, reducing the overflow of liquid metal, and protecting personal safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

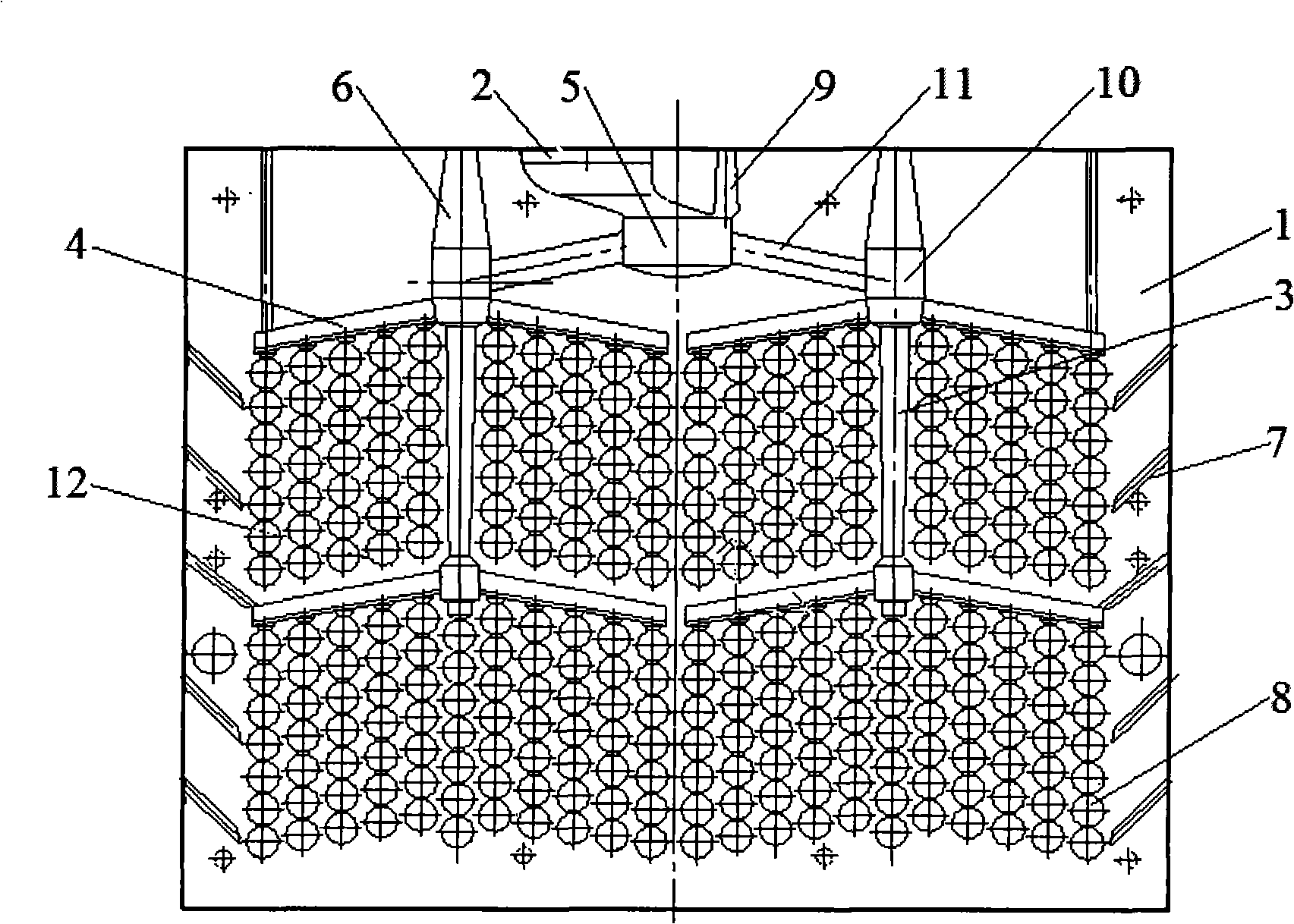

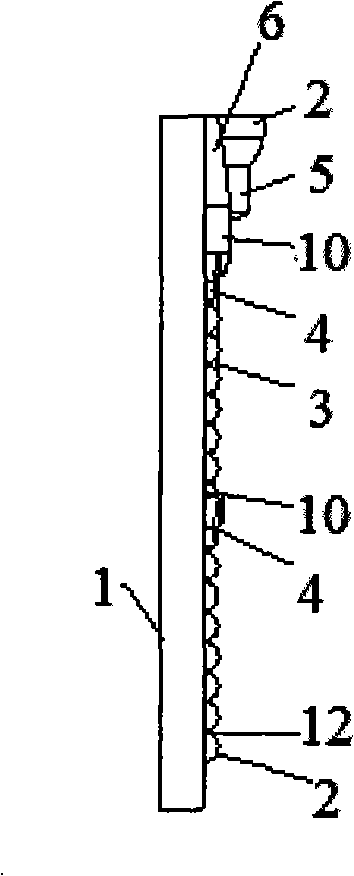

[0051] Such as figure 1 with image 3 As shown, the sprue riser 2 according to the present invention goes down from the opening position to the passage into the sprue riser diversion area 5, forming a bend, so that the part connecting the sprue riser 2 and the sprue riser diversion area 5 is Inclined pathway.

[0052] The above-mentioned structure ensures that after the vent hole 9 in the diversion area of the pouring riser is set, it will not interfere with the vent hole 2 in the diversion area of the pouring riser, and the vent hole 9 in the diversion area of the pouring riser 2 will give way to the position of the vent hole 9 in the diversion area of the pouring riser, and can slow down the impact of the liquid flow. The impact of the lower part of the pouring riser 2.

Embodiment 2

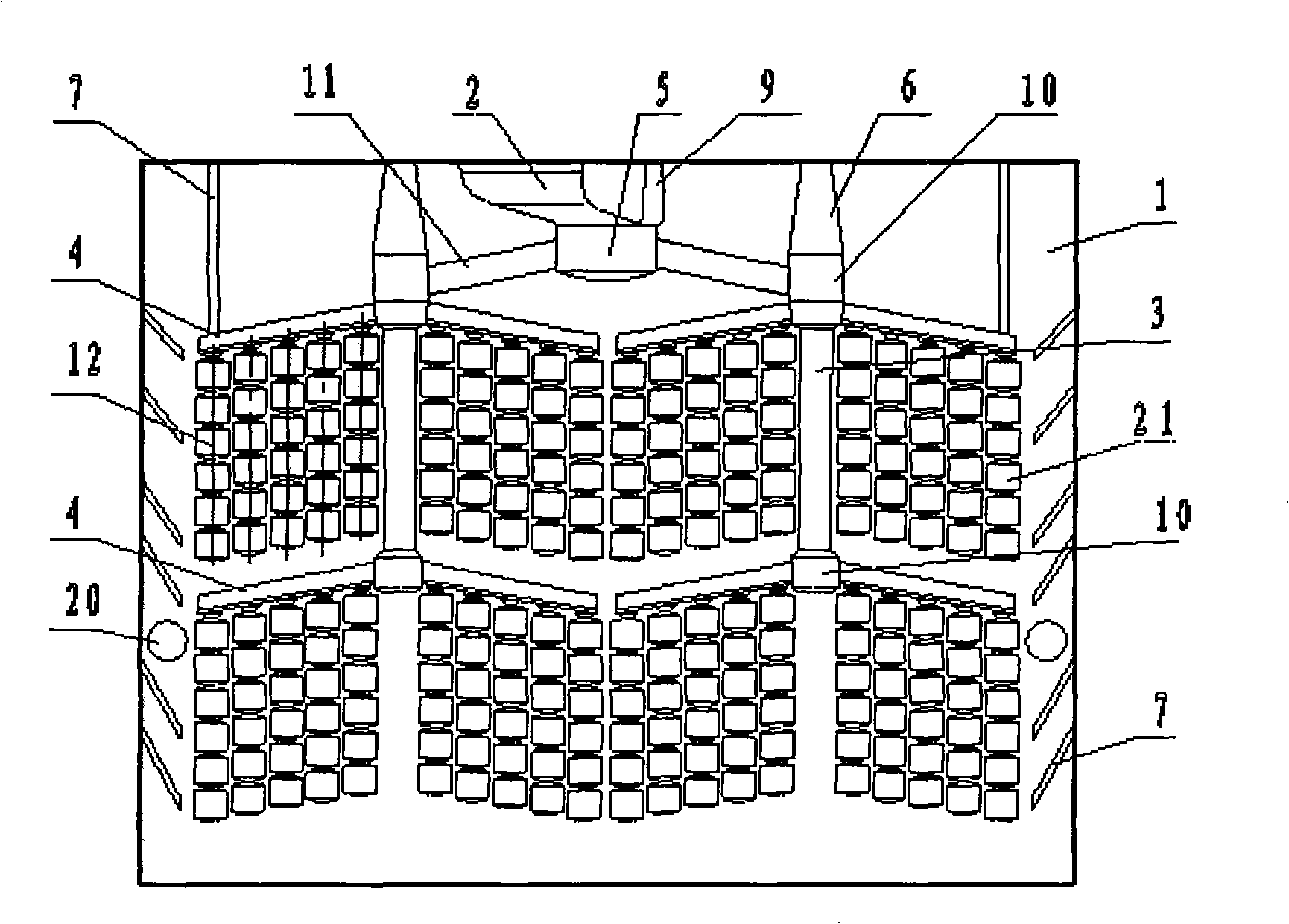

[0054] Casting balls and casting section molds according to the present invention are provided with a riser sub-runner 11, a main runner splitting area 10, a main runner 3 and a split runner 4. Channel 4 communicates, and the described sprue runner 11 communicates the sprue diversion area 5 with the main runner 3, and the main runner diversion area 10 is arranged between the main runner 3 and the split sprue Road 4 connection location.

[0055] Such as figure 1 with image 3 As shown, the runner is designed as the main runner 3 and the split runner 4, and the flow of liquid metal is accelerated by using the principle of the center of gravity downward.

[0056] The main runner 3 allows the liquid metal to flow and inject quickly downwards, and the split runner 4 divides the liquid metal in the main runner 3 into the molding cavity of the casting ball and the casting segment model, and the liquid metal is instantly absorbed by the acceleration of gravity. In the cavity, durin...

Embodiment 3

[0060] Such as Figure 1 to Figure 4 As shown, the main runner 3 of the present invention is vertically arranged, and its number is more than one; at the upper end of the main runner 3, a feeding riser 6 is provided.

[0061] The main sprue 3 is set vertically downward, the two sides of the split sprue 4 are placed obliquely downward from the middle to both sides, and the casting ball and the casting segment model are vertically connected to the split sprue 4 in series. The overall arrangement is vertically downward and relatively inclined. Compared with the existing vertical parting mold, the free area is small, the sand mold space is fully utilized, the space utilization rate is increased by about 8 percentage points, and the product process yield rate is relatively high. . The feed riser 6 is set above the main runner 3, which fully ensures the smooth flow and smooth exhaust of the liquid metal in the casting cavity, and can realize sufficient shrinkage during condensation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com