Backlight module and liquid crystal display

A technology of backlight module and liquid crystal display panel, which is applied to static indicators, semiconductor devices of light-emitting elements, instruments, etc., can solve the problems of cumbersome maintenance methods and so on.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

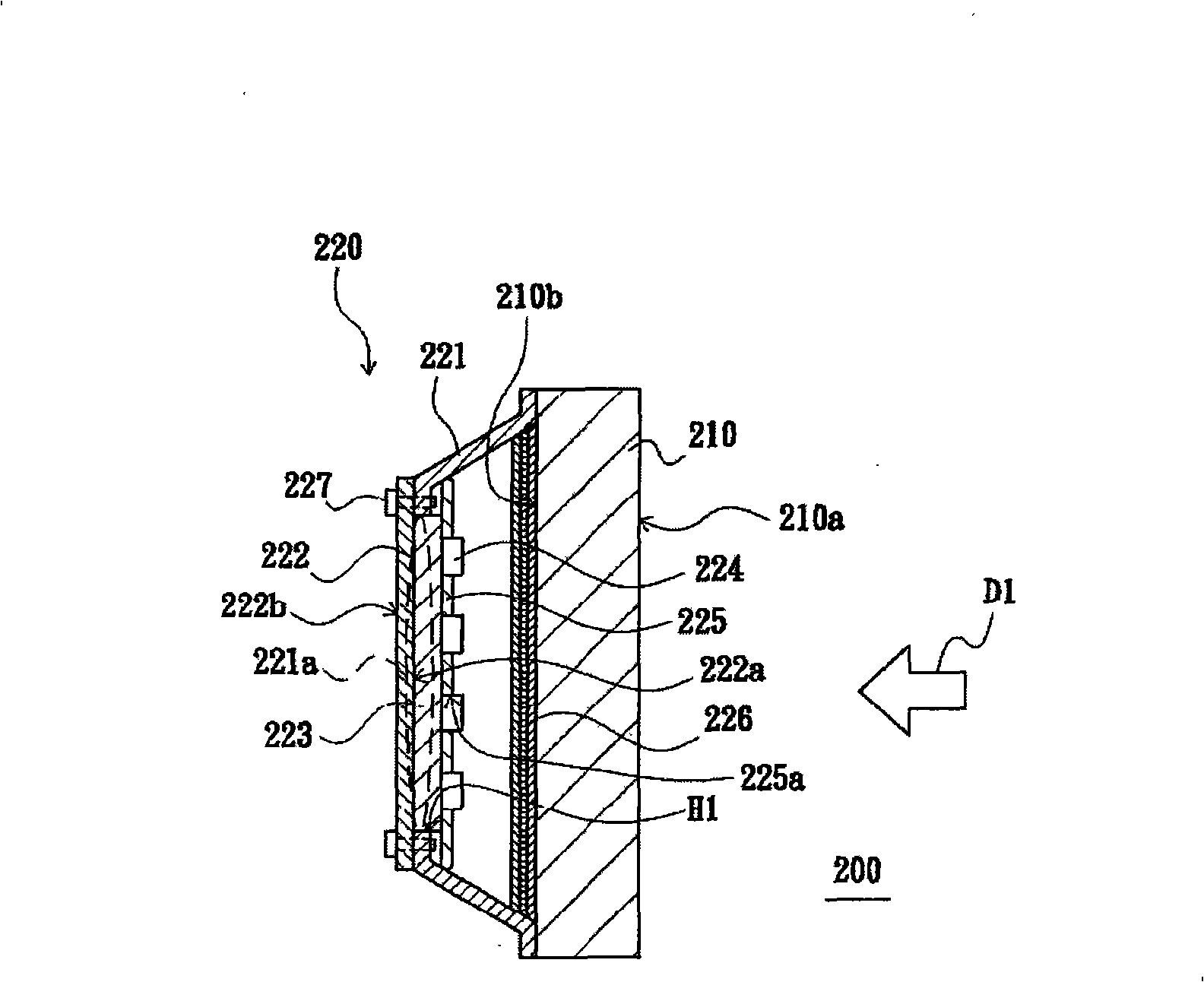

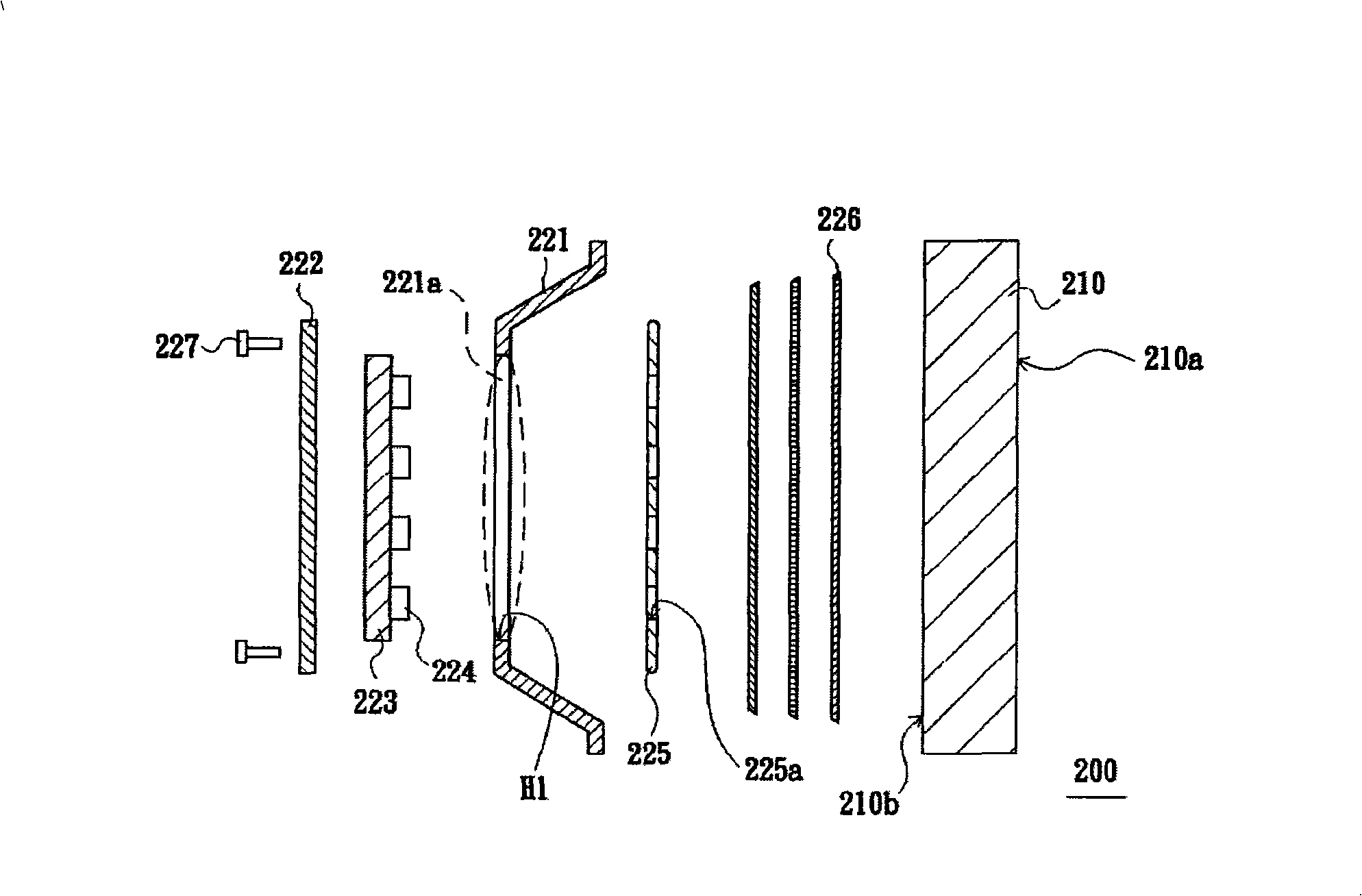

[0066] Figure 2A A schematic cross-sectional view of a liquid crystal display according to the first embodiment of the present invention is shown. Figure 2B show Figure 2A Schematic diagram of an exploded LCD display. Please refer to Figure 2A versus Figure 2B The liquid crystal display 200 of this embodiment includes a liquid crystal display panel 210 and a backlight module 220. The backlight module 220 includes a back plate 221, a carrier 222, a circuit board 223, a light-emitting element 224 (schematically shown in FIG. 2), a reflective sheet 225, a plurality of optical films 226, and a fixing member 227 (schematically shown in FIG. 2). Multiple). The back plate 221 has a through hole area 221a, and the through hole area 221a has a through hole H1. The back plate 221 is disposed in the non-display area 210 b of the liquid crystal display panel 210.

[0067] The carrier 222 is, for example, a plate body, which is disposed on the back plate 221 and has a first surface 222a ...

no. 2 example

[0072] Figure 3A A schematic cross-sectional view of a liquid crystal display according to the second embodiment of the present invention is shown. Figure 3B show Figure 3A Schematic diagram of the rear view of the backlight module. Please refer to Figure 3A versus Figure 3B The difference between the liquid crystal display 300 of the second embodiment and the liquid crystal display 200 of the first embodiment is that the supporting member 322 of the backlight module 320 of the second embodiment is pivotally connected to the back plate 321.

[0073] In detail, the circuit board 323 includes a first body 323a and a second body 323b. Some of the light-emitting elements 324 are disposed on the first body 323a, and some of the light-emitting elements 324 are disposed on the second body 323b. The carrier 322 includes a third body 322a and a fourth body 322b. The first body 323 a and the second body 323 b of the circuit board 323 are respectively disposed on the third body 322 a a...

no. 3 example

[0076] Figure 4A A schematic cross-sectional view of a liquid crystal display according to the third embodiment of the present invention is shown. Please refer to Figure 4A The backlight module 420 of the liquid crystal display 400 of the third embodiment includes a plurality of fixing members 428 (for example, screws) and a plurality of fixing members 429 (for example, screws). The circuit board 423 is detachably disposed between the back plate 421 and the carrier 422. The assembling method of the backlight module 420 of this embodiment is as follows. First, the circuit board 423 is fixed to the back plate 421 by these fixing members 428. Then, the supporting member 422, which is a board body, is fixed to the circuit board 423 and the back plate 421 by the fixing members 429. Generally speaking, the circuit board is fixed between the back plate 421 and the carrier 422 by these fixing members 428 and 429.

[0077] The carrier 422 of this embodiment can be designed as a plate bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com