Connector

A technology of connectors and connecting parts, which is applied in the direction of connection, fixed connection, and parts of connection devices, etc. It can solve the problems of limited increase in installation density, reliability of easy-to-disengage contact, difficulty in miniaturization of devices, etc., and achieves increased installation density, High contact reliability and effect of improved contact reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

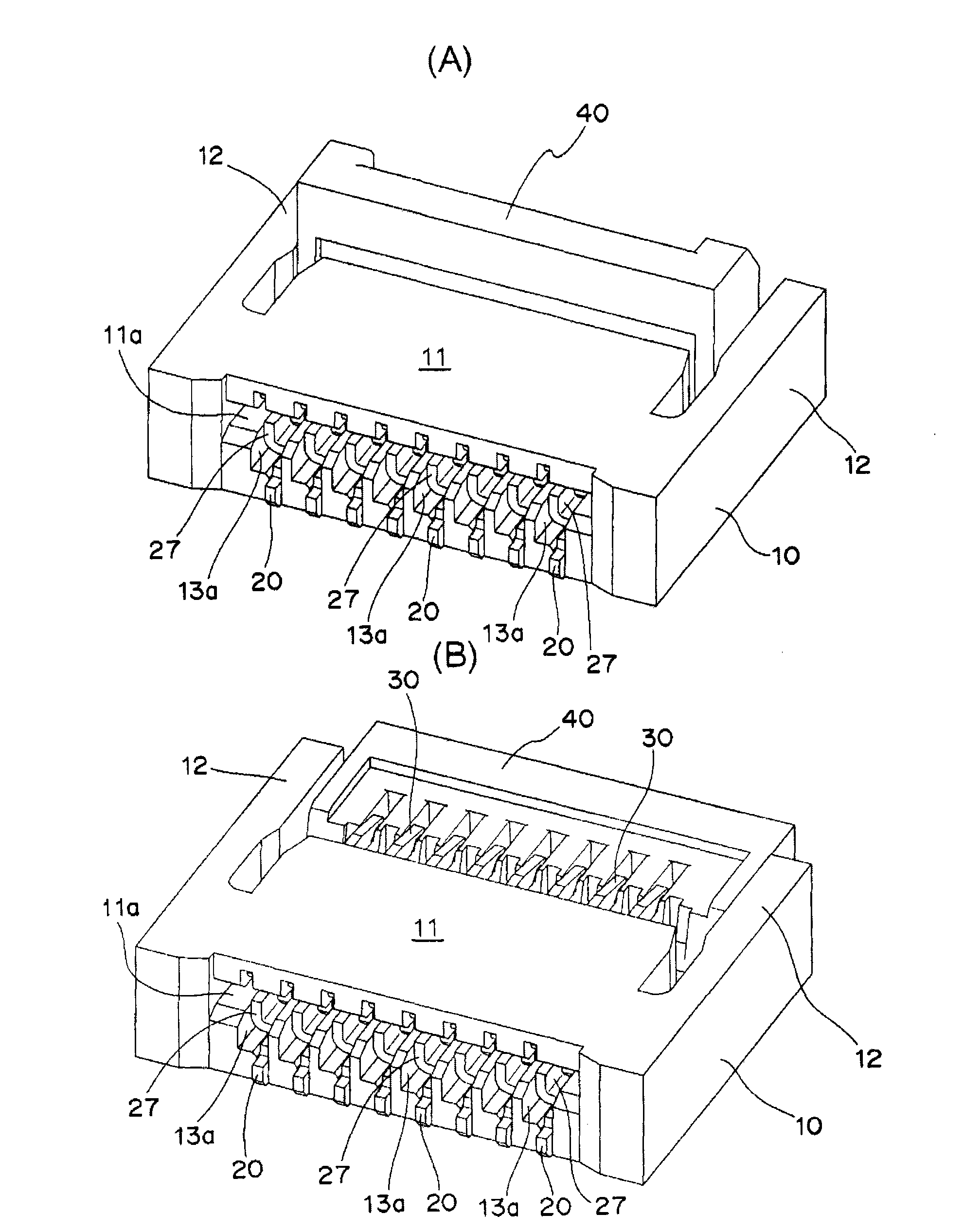

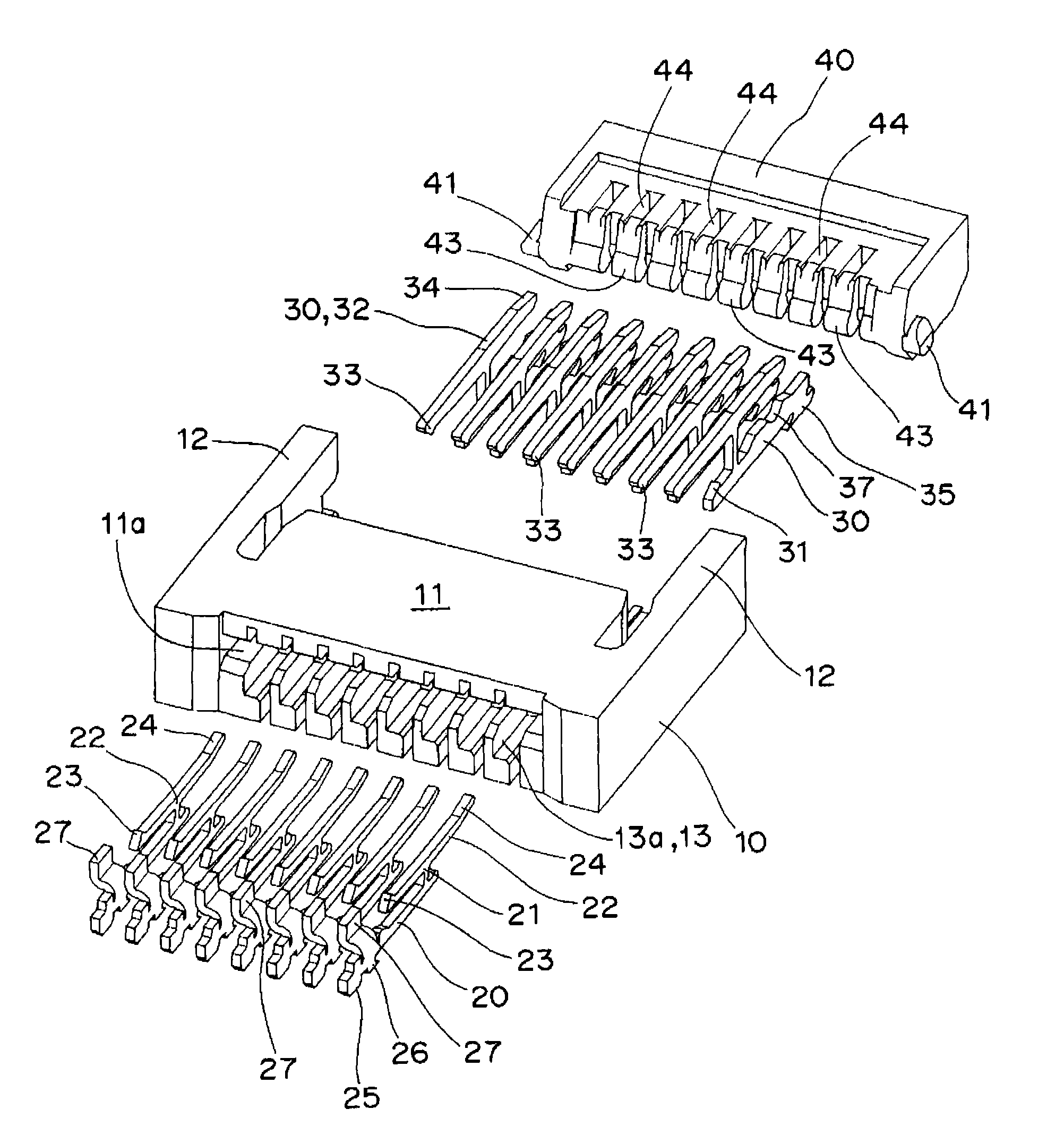

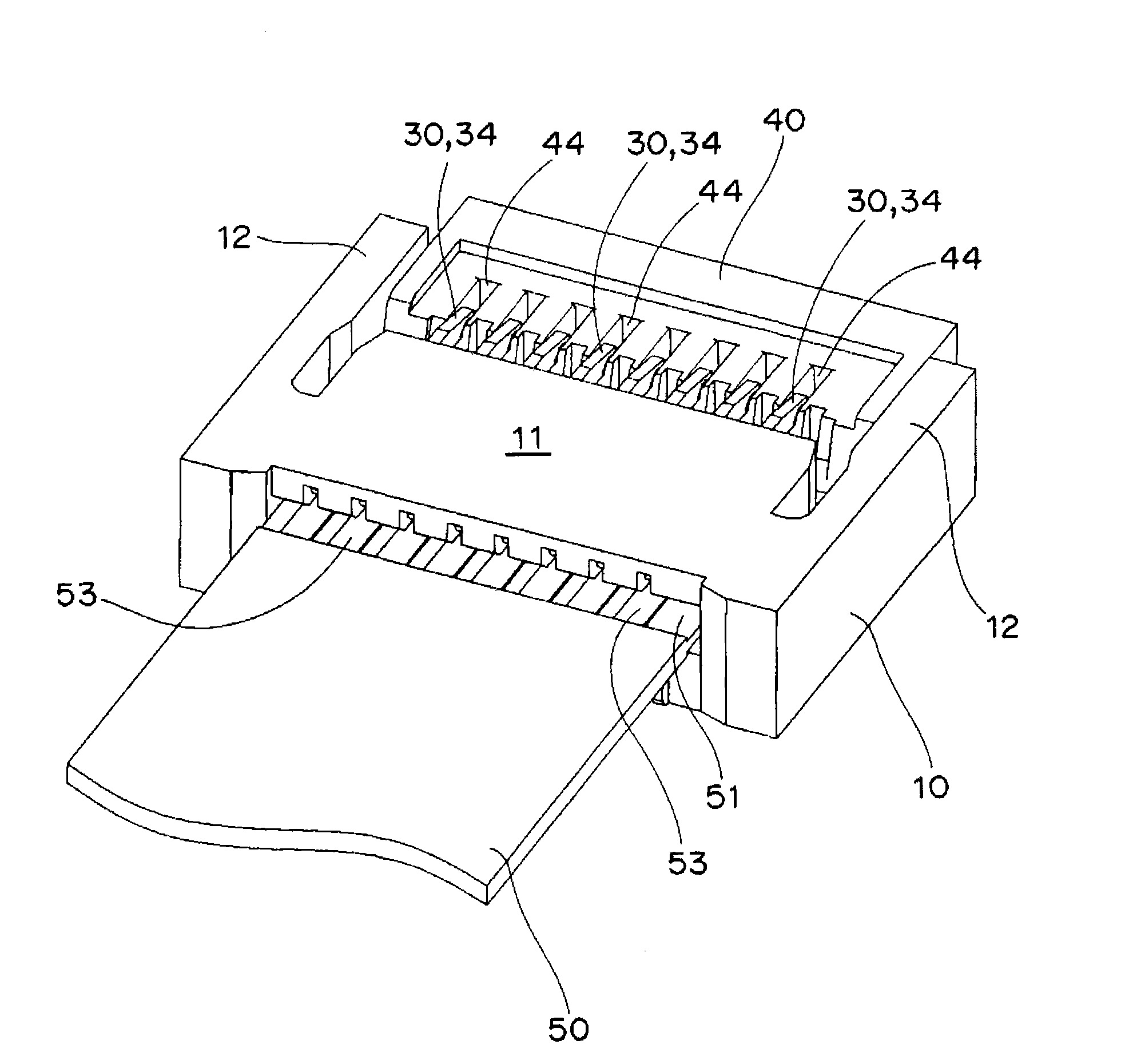

[0061] Refer to Figure 1~Figure 14 The embodiments of the present invention will be described.

[0062] Such as Figure 1 ~ Figure 3 As shown, the connector 10 of the first embodiment is roughly composed of a base 11, a first connection terminal 20, a second connection terminal 30, and an operating lever 40.

[0063] Such as Figure 5 As shown in (B), the base 11 has elastic arms 12 and 12 extending in parallel from one side edge to the back side of both end surfaces of the base 11, respectively. On the inward surface of the elastic arm portion 12, a guide tapered surface 12a is formed on the front end edge portion, and a shaft support slit 12b is formed on the back side thereof. In addition, such as Figure 5 As shown in (A), the base 11 is provided with an opening 11a on the front surface into which the front end 51 of the FPC 50 described later can be inserted, and a first insertion hole 13 with a stepped portion 13a for fitting is arranged side by side at a predetermined pitc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com