Tooling capable of automatically pasting the adhesive tape of the car decoration strip

A technology for automatic sticking and decorative strips, applied in workbenches, manufacturing tools, etc., can solve problems such as the inability to guarantee the consistency of batches, the inaccuracy of the sticking position, the peeling and bonding of the glue strips, etc., to achieve good consistency and reduce manpower. , the effect of improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

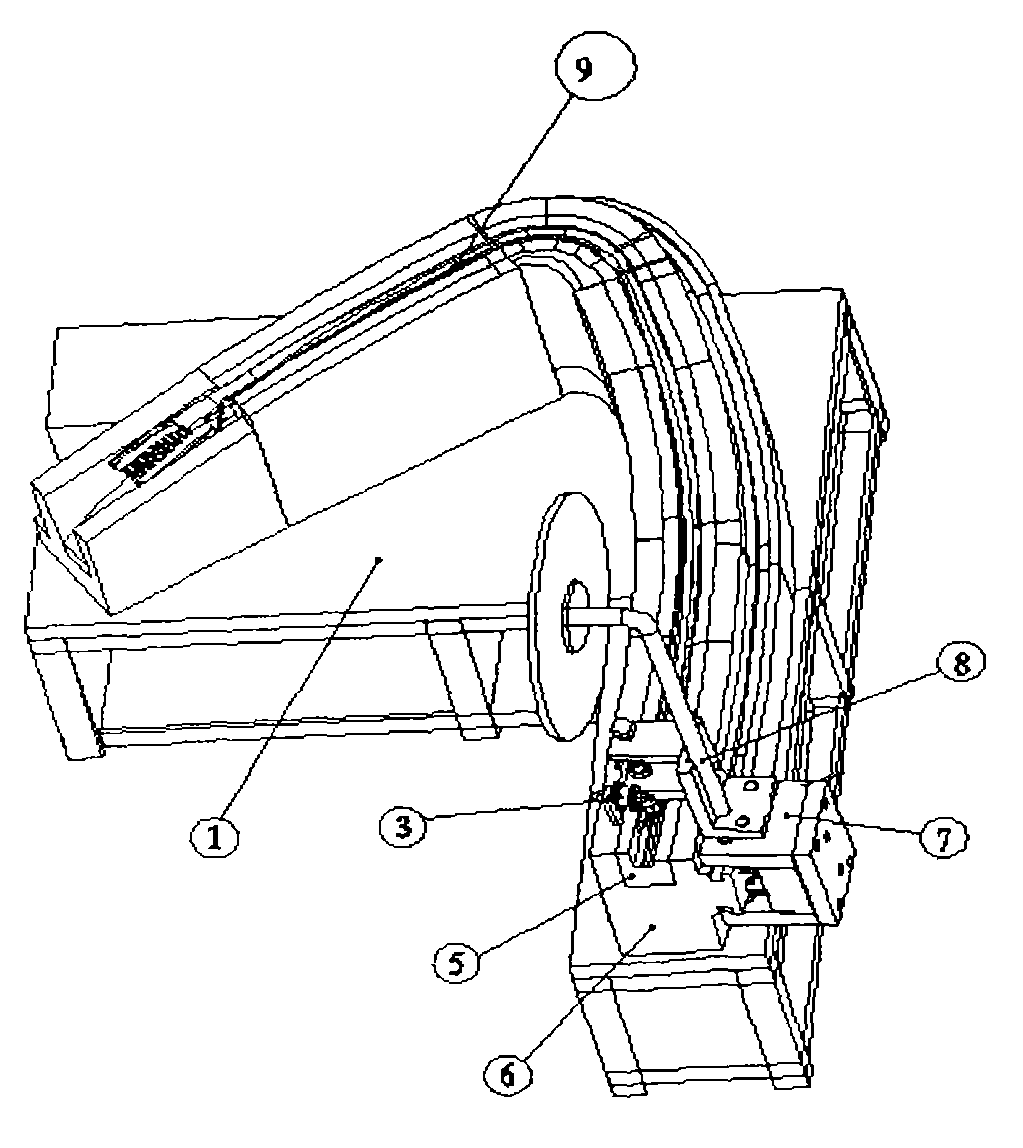

[0019] The concrete structure of this frock is described in detail below in conjunction with accompanying drawing:

[0020] see figure 1 , is a kind of tooling used for automatically pasting adhesive strips on car window frame trim strips, which includes a tooling table (1), a base (6), a tire membrane (5), a tape fixing frame (8), and a pressing device (3 ) and sliding system (7), etc. The base (6) is fixedly installed on the tooling table 1, the membrane (5) is installed in the base (6), the pressing device (3) is located directly above the membrane (5), and the adhesive tape fixing frame (8) It is connected with the sliding system (7), and the sliding system (7) is assembled on the base (6) through the guide chute on the side of the base (6).

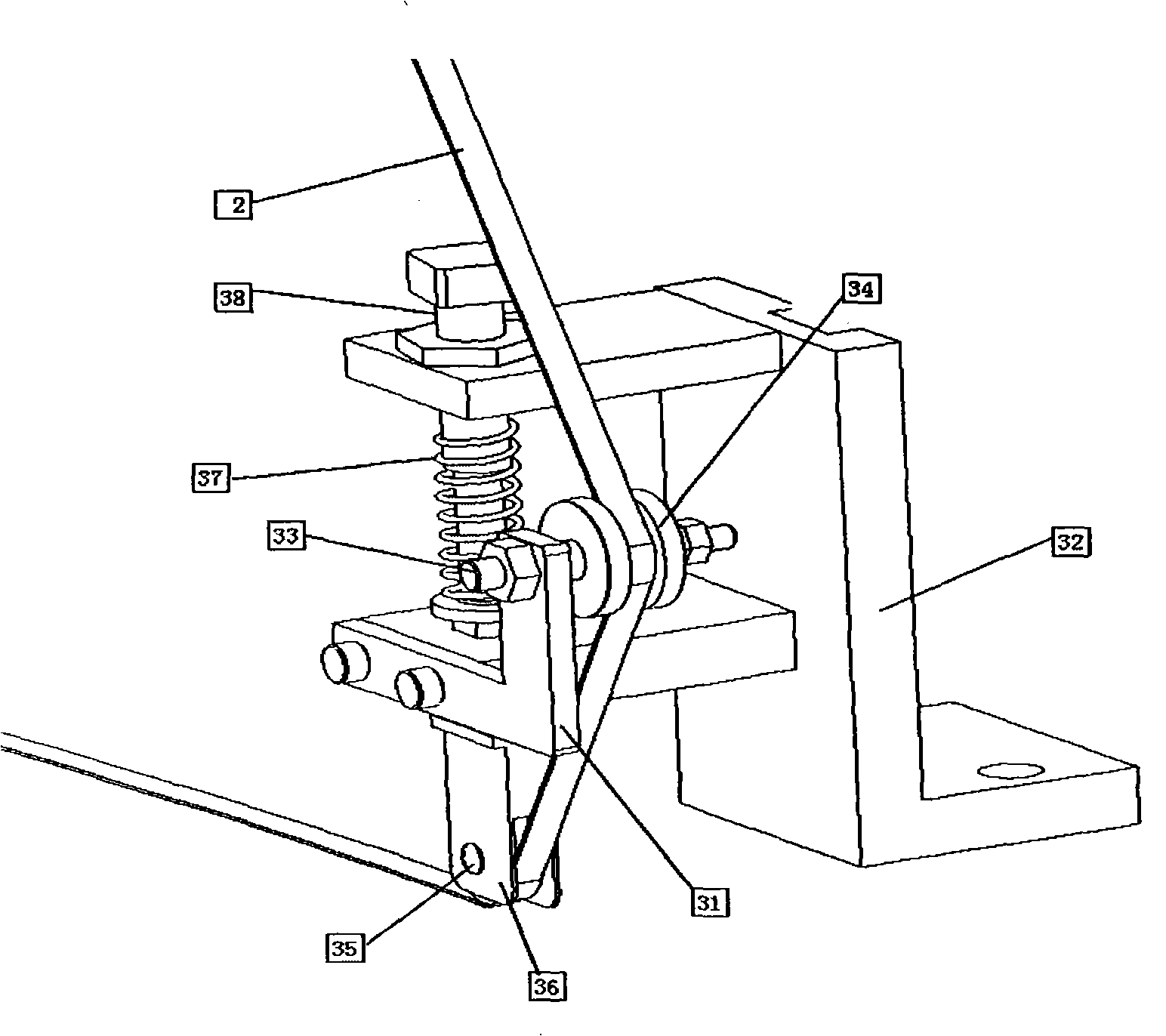

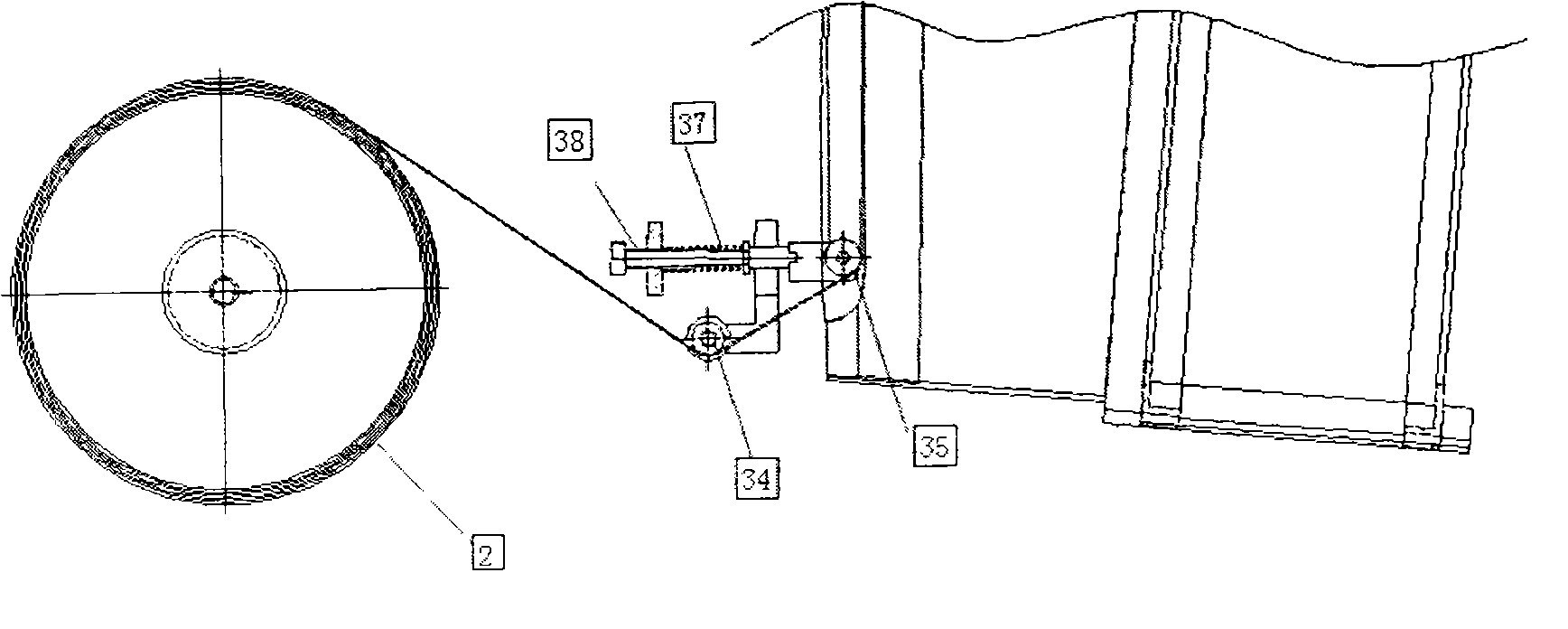

[0021] The concrete structure of sliding system (7) sees Figure 4 and Figure 5 , which is fixed on the operating frame (75) by the lower positioning bearing (71), the upper positioning bearing (73), the side positioning bearing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com