Zinc oxide nano-ultraviolet light sensor and preparation method thereof

A zinc oxide nanometer and sensor technology, which is applied in the direction of zinc oxide/zinc hydroxide, semiconductor devices, and final product manufacturing, and can solve problems such as the practical application of cumbersome and complicated processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

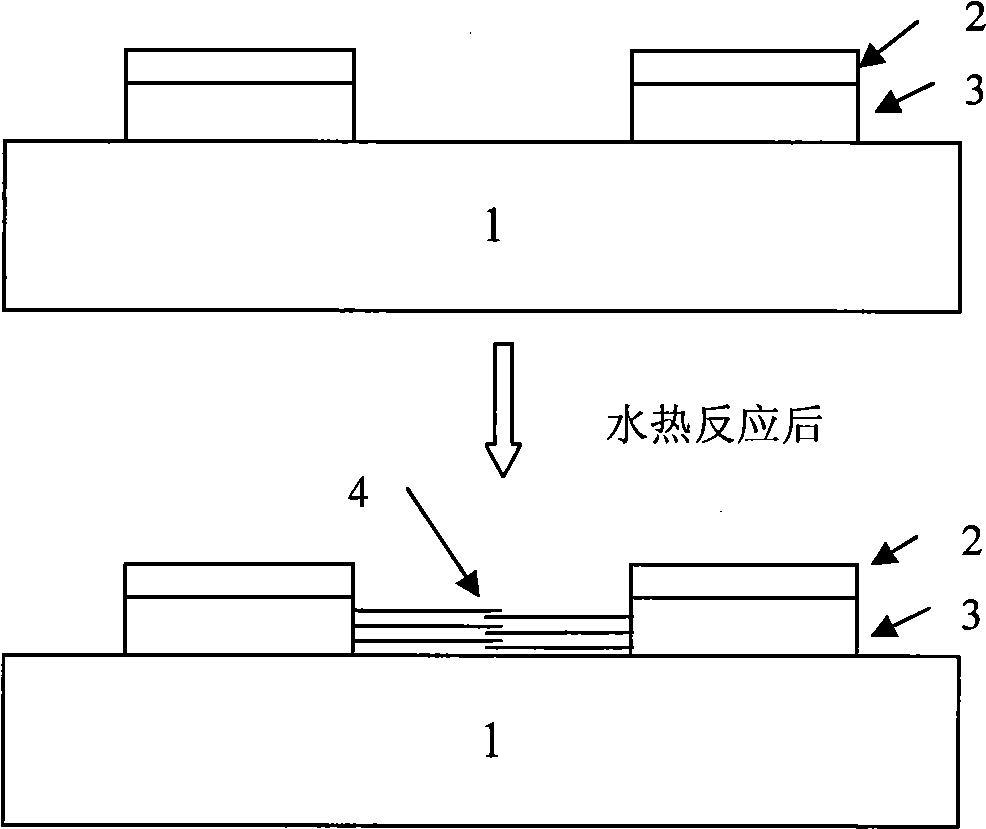

[0025] See attached figure 2 , in this example, ordinary glass is used as the substrate, and a traditional photolithography mask is used as an example to illustrate. Specific steps are as follows:

[0026] 1. Use traditional semiconductor technology to clean ordinary blank glass substrates.

[0027] 2. Make a layer of photoresist mask on the glass substrate using traditional photolithography technology.

[0028] 3. Deposit a layer of 300nm ZnO thin film on the glass substrate as the seed layer.

[0029] 4. Deposit a layer of 50nm Sn film on the substrate as a passivation layer and also as an electrode.

[0030] 5. Use the traditional photoresist removal method to wash off the photoresist to obtain the required interdigitated electrodes.

[0031] 6. A high-pressure hydrothermal reactor with polytetrafluoroethylene lining is used as the reaction vessel, and the aqueous solution is zinc acetate and hexamethylene tetramine with a concentration of 0.005mol / L. Put the sample f...

Embodiment 2

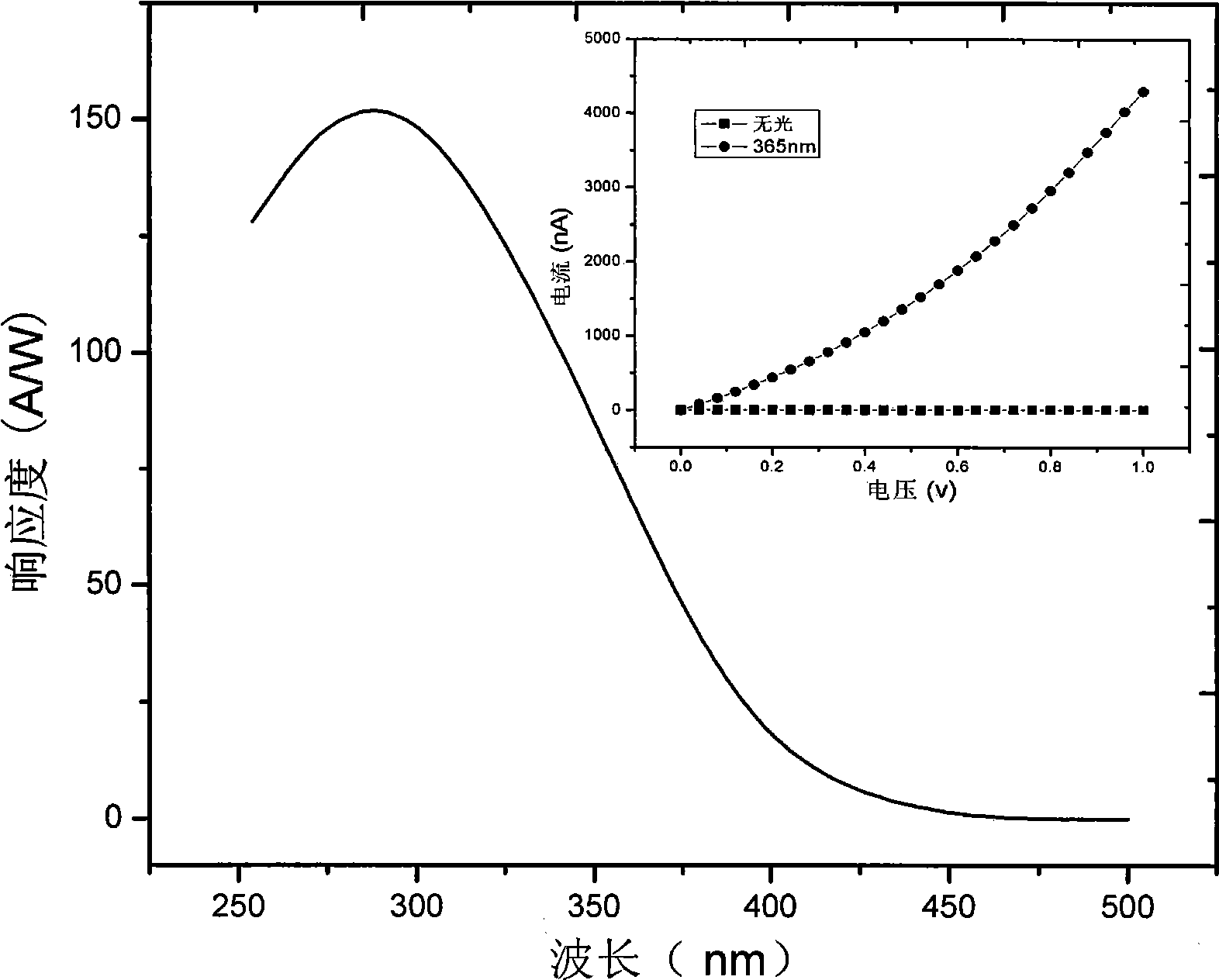

[0035] See attached image 3 , in this example, silicon dioxide is used as the substrate, and a traditional photolithography mask is used as an example to illustrate.

[0036] Specific steps are as follows:

[0037] 1. Clean the silicon dioxide substrate using traditional semiconductor processes.

[0038] 2. Make a layer of photoresist mask on the silicon dioxide substrate using traditional photolithography technology.

[0039]3. Deposit a layer of 200nm aluminum-doped zinc oxide film on the silicon dioxide substrate as a seed layer.

[0040] 4. Deposit a layer of 50nm Cr thin film on the silicon dioxide substrate as a passivation layer, and also as an electrode.

[0041] 5. Use the traditional photoresist removal method to wash off the photoresist to obtain the required interdigitated electrodes.

[0042] 6. A high-pressure hydrothermal reactor lined with polytetrafluoroethylene is used as the reaction vessel, and the aqueous solution is zinc acetate and hexamethylene tet...

Embodiment 3

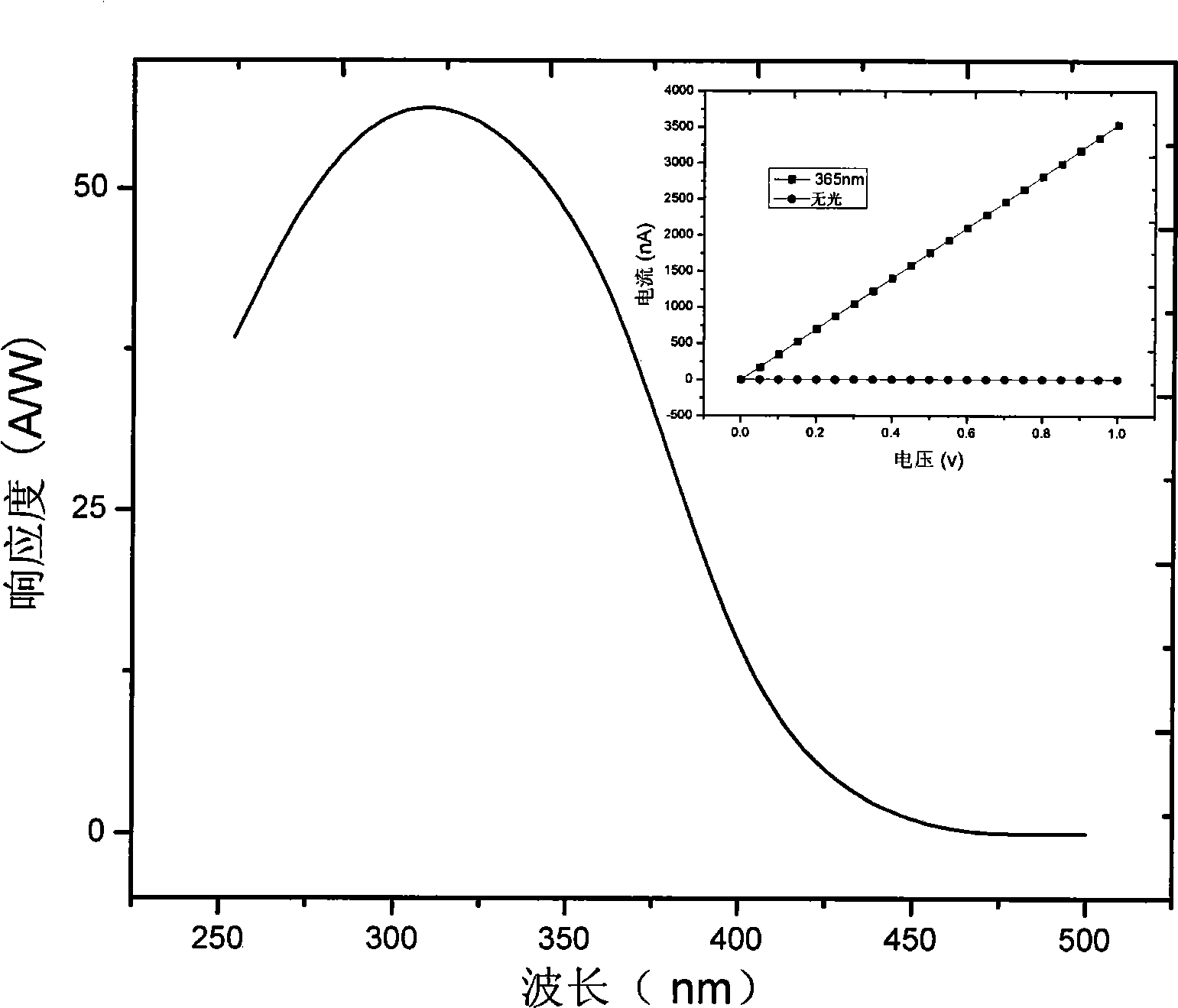

[0046] See attached Figure 4 , In this example, the flexible substrate PET (polyethylene terephthalate) is used as the substrate, and the metal mask is used as an example to illustrate. Specific steps are as follows:

[0047] 1. Clean the PET flexible substrate with absolute ethanol and deionized water and dry it for use.

[0048] 2. Using a metal mask as a mask, deposit a 30nm gold thin film on the substrate as a seed layer.

[0049] 3. Deposit a layer of 50nm ITO film on the substrate as a passivation layer and also as an electrode.

[0050] 4. A high-pressure hydrothermal reactor with polytetrafluoroethylene lining is used as the reaction vessel, and the aqueous solution is zinc acetate and hexamethylene tetramine with a concentration of 0.001mol / L. Put the sample face down and place it horizontally below the liquid level in the reaction kettle, put the autoclave in a constant temperature box, and keep it at 65°C for three hours.

[0051] 5. Take out the sample, rinse ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap