Packaging structure and packaging method of optoelectronic device

An optoelectronic device and packaging method technology, applied in the field of optoelectronics, can solve the problems of device performance degradation, material negative effects, device performance degradation, etc., to achieve the effects of optimizing device performance, improving barrier function, and prolonging device life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

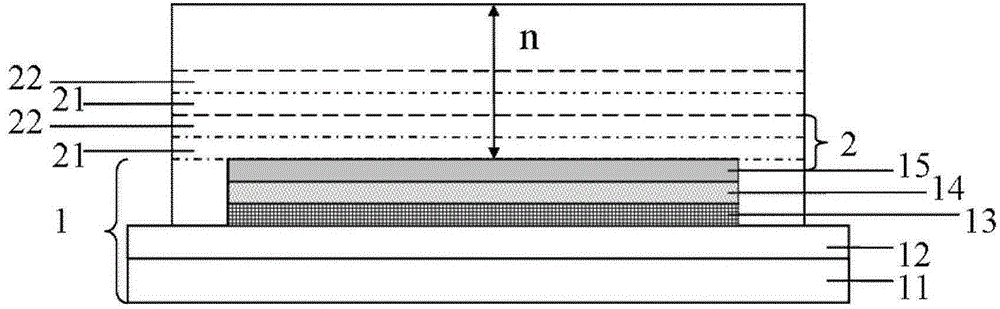

[0030] Such as figure 1 As shown, 1 is an organic electroluminescent device, the anode layer 12 is ITO, and the hole transport layer 13 is N,N'-bis(naphthylidene-1-yl)-N,N'-bis(phenyl) - benzidine (NPB), electron transport layer 14 is 1,3,5-(triN-phenyl-2-benzimidazole-2) benzene 41 (TPBi), cathode layer 15 is Mg:Ag alloy, inorganic package Material layer 21 is Al 2 o 3 , the UV curable resin layer 22 includes 58% shellac, 3% glycerin, 0.97% lead oxide, 4% toluene diisocyanate, 9% trimethylol propane, 0.01% hydroquinone, 11% tetrahydrofuran, 7% 2-hydroxyethyl methacrylate, 0.02% dibutyltin dilaurate, 2% 2,2-dimethoxy-phenyl ketone and 5% trimethylol Propane triacrylate, the period number n is 20, and the device structure is:

[0031] Glass substrate / ITO / NPB(50nm) / TPBi(30nm) / Mg:Ag(200nm) / [Al 2 o 3 (200nm) / UV curable resin (100nm)] 20

[0032] The preparation method is as follows:

[0033] ①Use detergent, acetone solution, ethanol solution and deionized water to ultraso...

Embodiment 2

[0042] Such as figure 1 As shown, 1 is an organic electroluminescent device, the anode layer 12 is ITO, and the hole transport layer 13 is N,N'-bis(naphthylidene-1-yl)-N,N'-bis(phenyl) - benzidine (NPB), electron transport layer 14 is 1,3,5-(triN-phenyl-2-benzimidazole-2) benzene 41 (TPBi), cathode layer 15 is Mg:Ag alloy, inorganic package Material layer 21 is Al 2 o 3 , the UV curable resin layer 22 includes 53% shellac, 5% glycerin, 0.005% lead oxide, 4% toluene diisocyanate, 9% trimethylol propane, 0.005% hydroquinone, 12% tetrahydrofuran, 7% 2-hydroxyethyl methacrylate, 0.99% dibutyltin dilaurate, 3% 2,2-dimethoxy-phenyl ketone and 6% trimethylol Propane triacrylate, the period number n is 16, and the device structure is:

[0043] Glass substrate / ITO / NPB(50nm) / TPBi(30nm) / Mg:Ag(200nm) / [Al 2 o 3 (200nm) / UV curable resin (100nm)] 16

[0044] The preparation method is similar to Example 1.

Embodiment 3

[0046] Such as figure 1 As shown, 1 is an organic electroluminescent device, the anode layer 12 is ITO, and the hole transport layer 13 is N,N'-bis(naphthylidene-1-yl)-N,N'-bis(phenyl) - benzidine (NPB), electron transport layer 14 is 1,3,5-(triN-phenyl-2-benzimidazole-2) benzene 41 (TPBi), cathode layer 15 is Mg:Ag alloy, inorganic package Material layer 21 is Al 2 o 3 , the UV curable resin layer 22 includes 39% shellac, 5% glycerol, 0.003% lead oxide, 7% toluene diisocyanate, 10% trimethylol propane, 0.097% hydroquinone, 10% tetrahydrofuran, 7.9% 2-hydroxyethyl methacrylate, 1% dibutyltin dilaurate, 9% 2,2-dimethoxy-phenyl ketone and 11% trimethylol Propane triacrylate, the period number n is 12, and the device structure is:

[0047] Glass substrate / ITO / NPB(50nm) / TPBi(30nm) / Mg:Ag(200nm) / [Al 2 o 3 (200nm) / UV curable resin (100nm)] 12

[0048] The preparation method is similar to Example 1.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap