Integrated equipment of dry concentration, rough concentration and fine concentration of waste disposal site and technique thereof

A technology of dumping and dry separation, applied in solid separation, chemical instruments and methods, magnetic separation, etc., can solve the problems of difficult selection of production line site selection, increased one-time investment, and impact on production efficiency, and achieve production organization Fluency, ore grade improvement, and sufficient sorting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

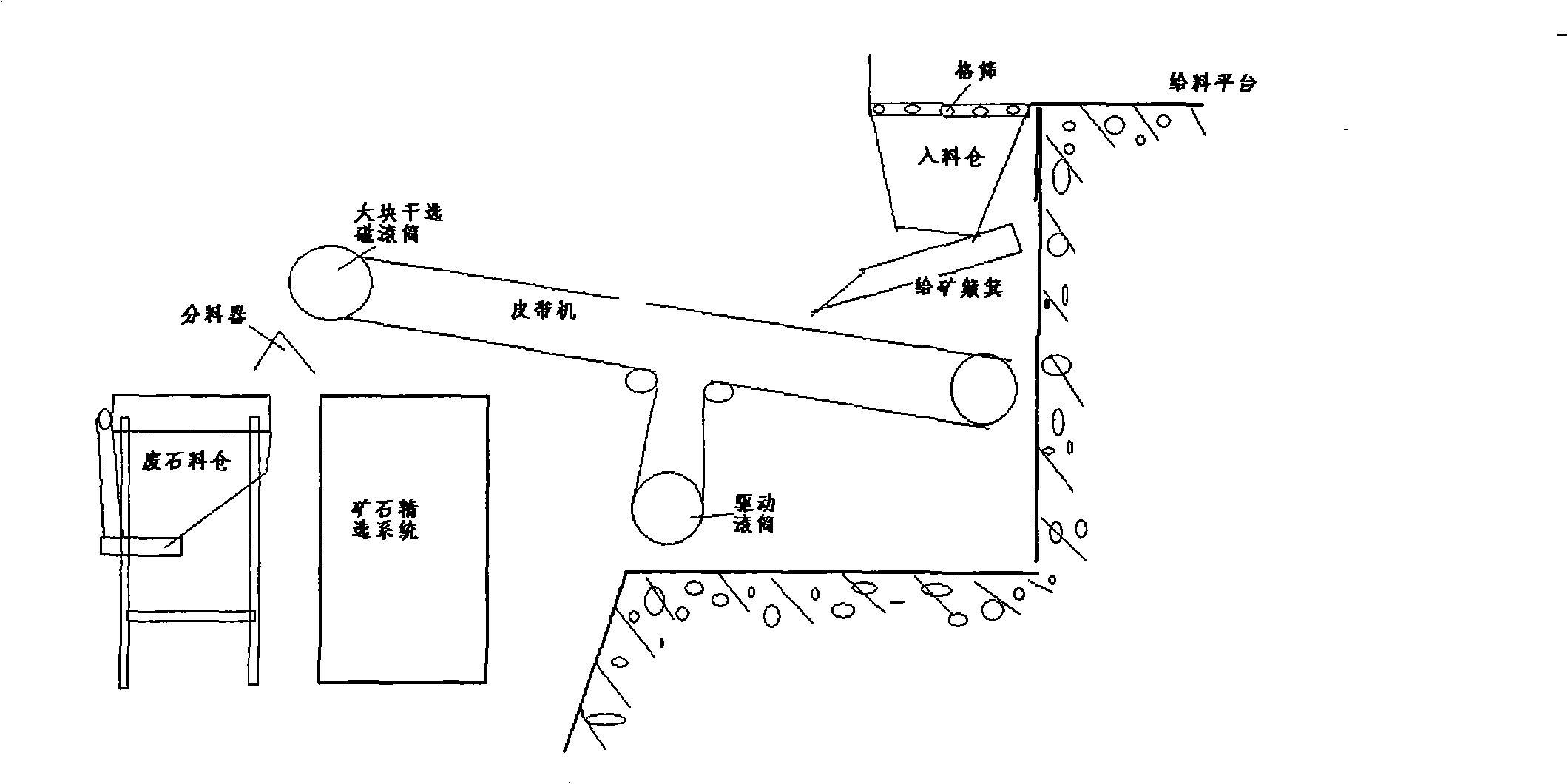

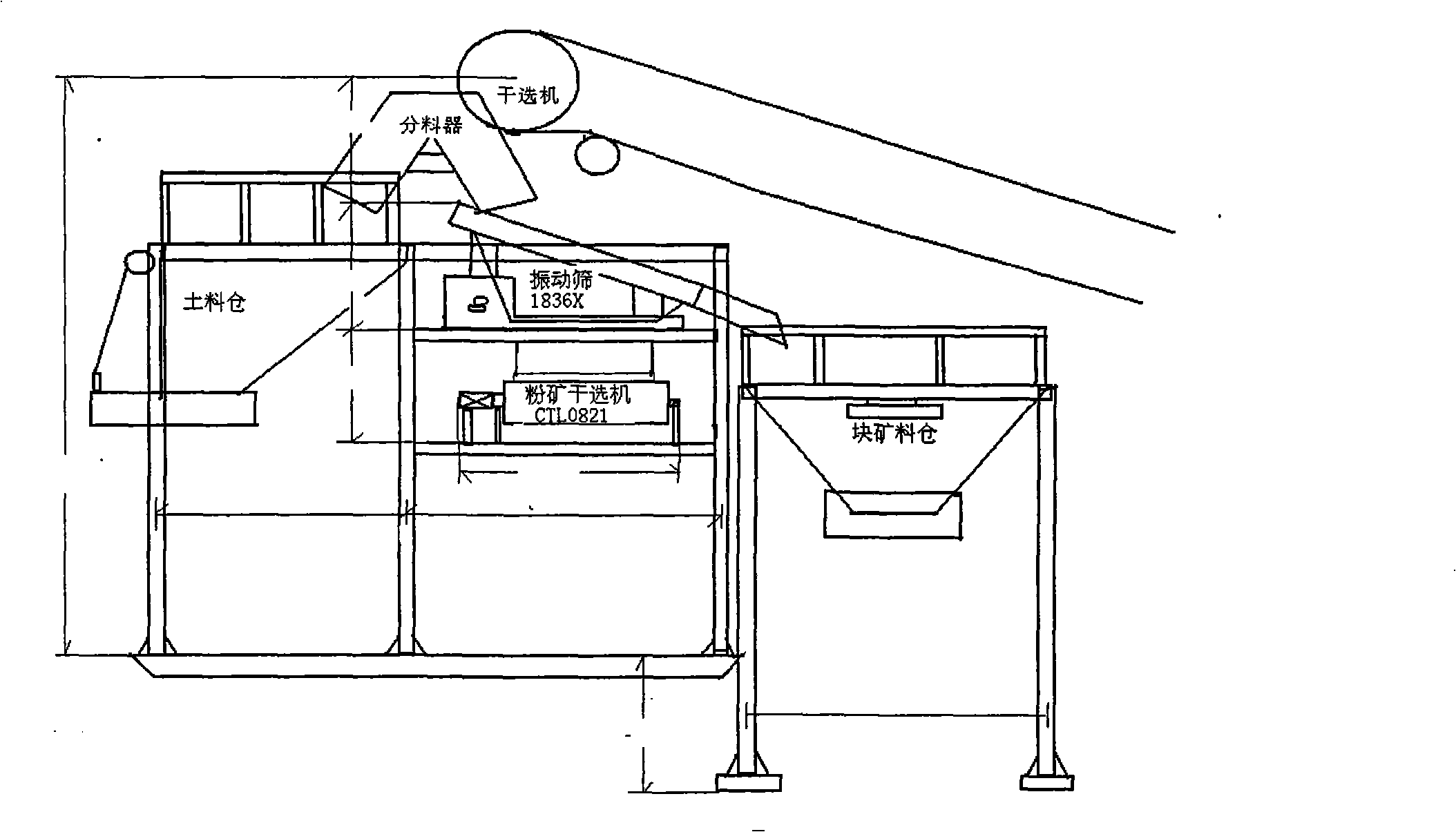

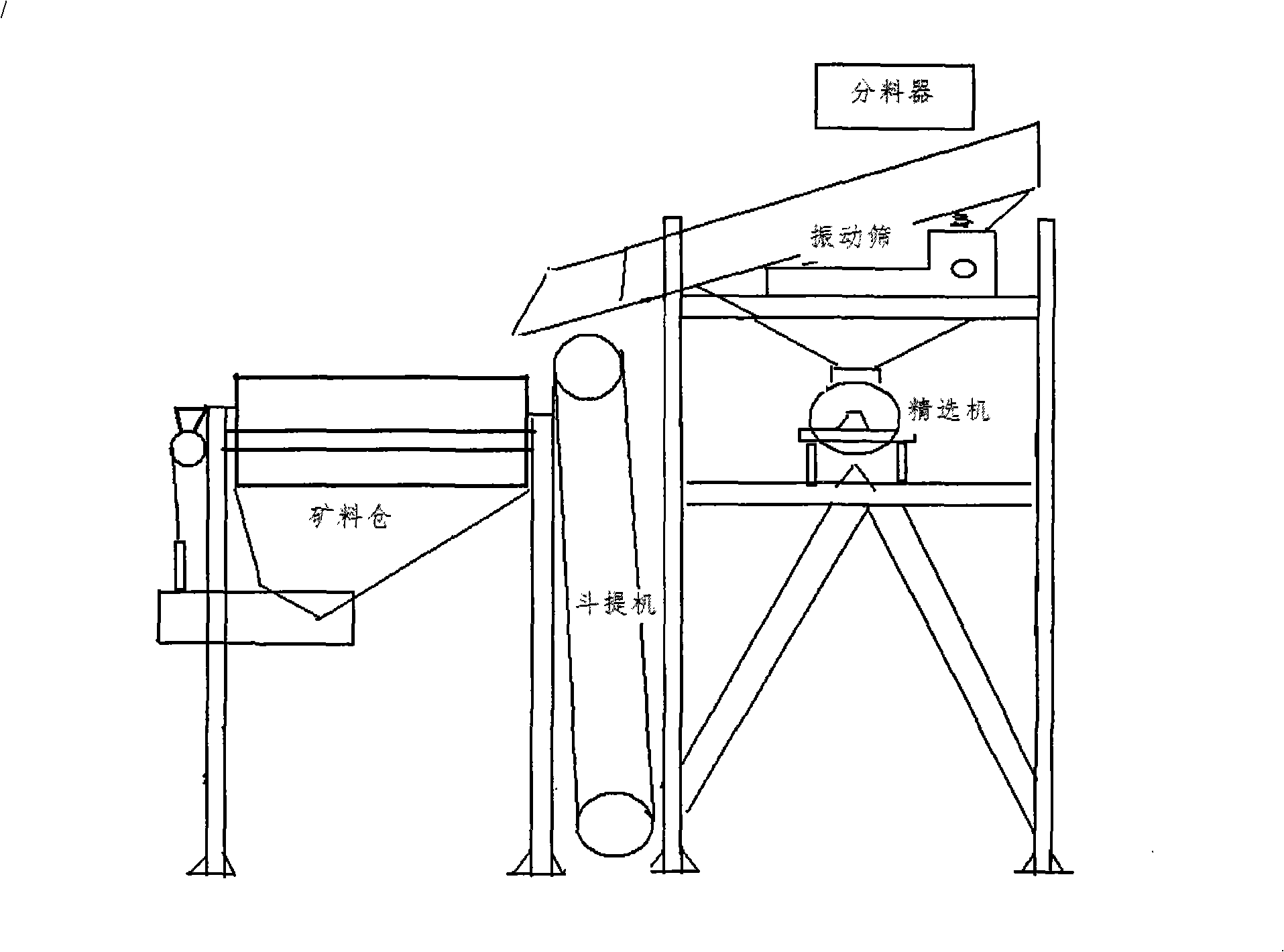

[0023] Implementation status: The implementation status of the rough and fine integrated dry separator for the construction of the second horse workshop in Dashihe Iron Mine of Shougang Mining Company is as follows:

[0024] (1) The size of the entrance of the feeding bin is 4m*6m. The bar-shaped screen is made of ∮219 steel pipe on the bin. The distance between the screen holes is 300mm, which can meet the straight turning strength of a 42-ton mine car. The outlet of the feeding bin is 1000mm*400mm, and a vibrating dustpan is installed. .

[0025] (2) Conveyor belt, width 1400mm, length 35 meters, middle transmission.

[0026] (3) Large block dry separator (magnetic drum): CTDG1600 large-size dry separator is selected, the field strength of the cylinder surface is 4000 Oersted; the field strength at 250mm from the cylinder surface is 500 Oersted; the maximum processing particle size is 350mm: magnetic package Angle 135°

[0027] (4) Waste rock silo: 32 liters, meeting the c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com