Hybrid locking bone fracture plate system and matching screw driver

A bone plate and screwdriver technology, applied in the field of internal fixation systems, can solve the problems of reduced quality of reduction, increased difficulty, failure of internal fixation, etc., and achieves the effect of avoiding secondary displacement and maintaining stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] Attached below figure 1 to attach Figure 9 The hybrid locking bone plate system and its driver of the present invention are further described in detail.

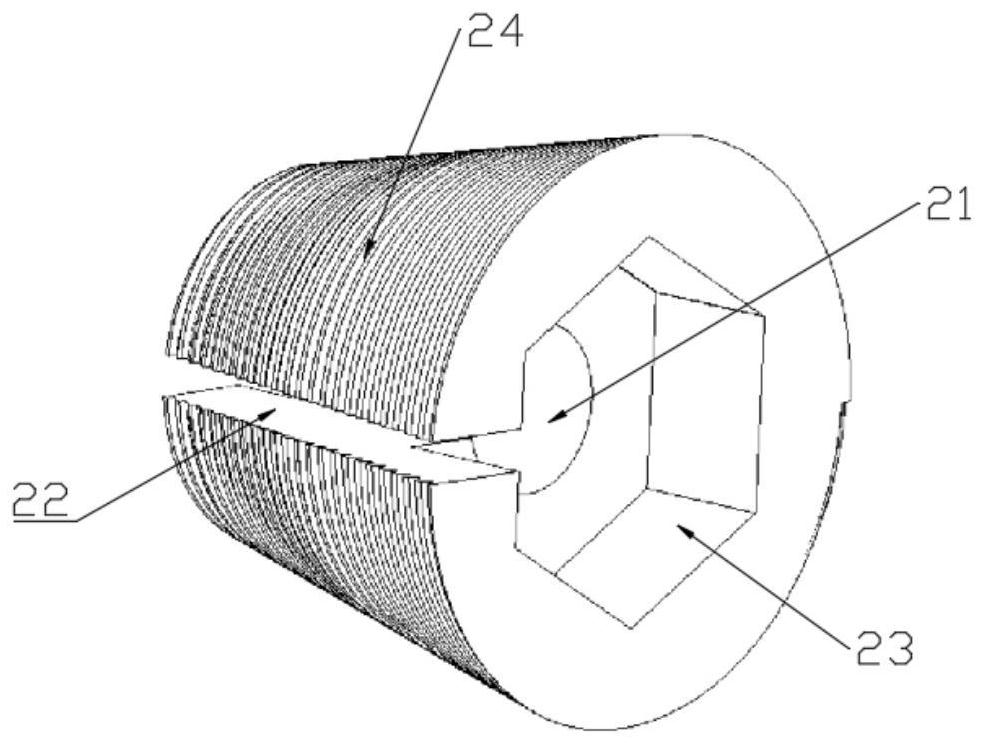

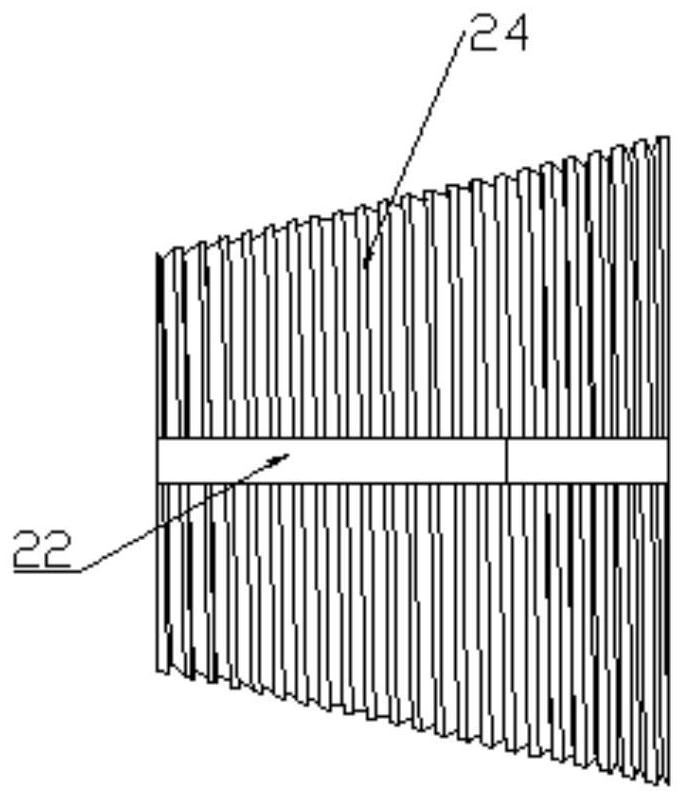

[0044] Such as Figure 1-7 and Figure 9 As shown, the present invention discloses a hybrid locking bone plate system, including a pin A, a collet B and a bone plate C.

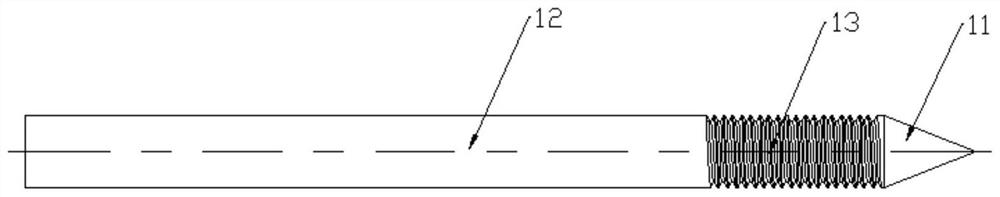

[0045] The needle A is a cylindrical structure, such as figure 1 As shown, one end of the needle A is a tip 11 and the other end is a rod 12 . In this embodiment, the end of the rod portion 12 close to the tip 11 is provided with a third thread 13 to increase the riveting effect of the needle A in the bone. Certainly, the outer surface of the rod portion 12 may also be a smooth outer surface.

[0046] Because of its fast implantation speed and less damage to the bone, the needle A lays the foundation for resetting the fracture and adjusting the positional relationship between the bone and the bone plate, which helps to improve the quality of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com