Early-detaching combined template system

A technology of combined formwork and formwork, which is applied in the field preparation of formwork/formwork/work frame, pillars, and building components, etc., can solve the problems of high labor intensity, restrictions, and low efficiency of formwork construction for operators, and achieve saving in turn. Field capacity, safe use, and high efficiency in assembly and disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described below in conjunction with the accompanying drawings, but the present invention is not limited to the scope of the described embodiments.

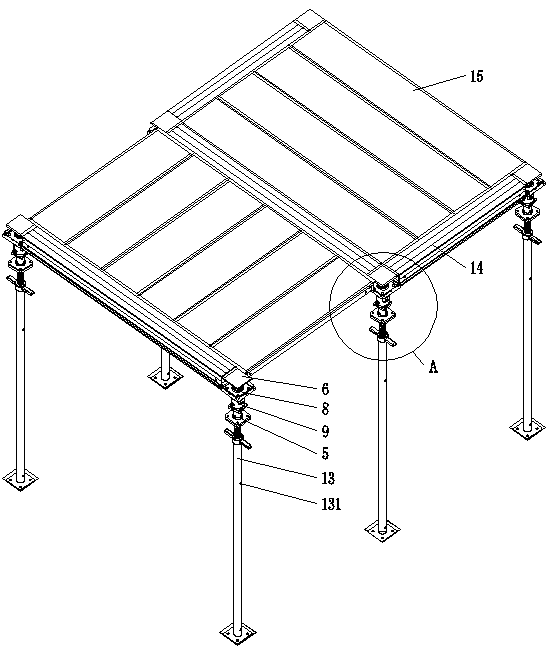

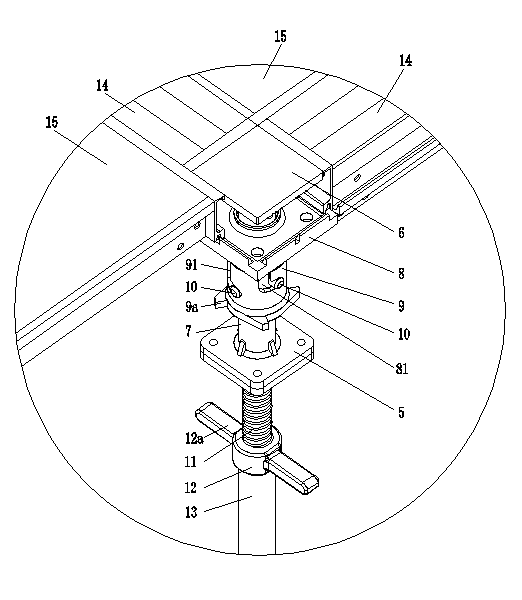

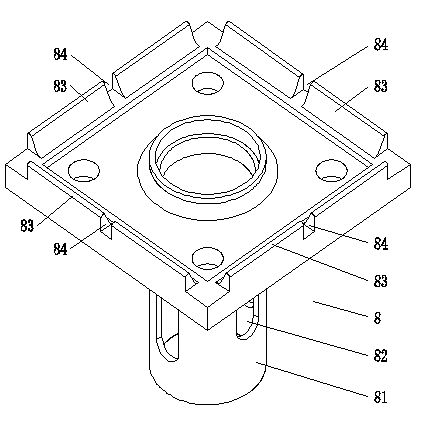

[0040] see figure 1 , figure 2 , image 3 , an early demolition combined formwork system, comprising a plurality of supporting columns 13 and formwork components, the supporting columns 13 are provided with an early dismantling mechanism, the top plate 6 and the bracket 8 of the early dismantling mechanism are in a right-angled quadrilateral, and the multiple early dismantling mechanisms Bracket 8 forms the support to formwork assembly, and the top plate 6 of a plurality of early demolition mechanisms and formwork assembly form the lower support form of pouring body, it is characterized in that, described formwork assembly is made up of a plurality of rectangular beam parts 14 and a plurality of rectangular The template part 15 is composed of the beam part 14 supported on the bracket...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com