Pin tool for friction stir welding and current carrying friction stir welding method

A technology of friction stir welding and friction stir, which is applied in welding equipment, welding medium, welding equipment, etc., can solve the problems of harsh working environment, difficult weld structure, and low service life, so as to reduce welding cost, enhance joint performance, The effect of improving the service life

Inactive Publication Date: 2011-01-05

CHONGQING UNIV

View PDF1 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

1) Insufficient heat input for friction stir and plastic deformation, complex superplasticity, recovery and recrystallization, and phase transformation processes, making it difficult to form a good weld structure;

2) The working environment of the stirring head is harsh, the cost of the stirring head is very high, and the service life is low;

3) Low welding efficiency and poor molding quality

At the same time, even in the friction stir welding of non-ferrous metals with low melting point, there are welding defects, the process requirements are relatively strict, the welding process window is narrow, the friction stir equipment is complicated, and the practical application of friction stir welding technology is limited.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

example 1

example 2

example 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

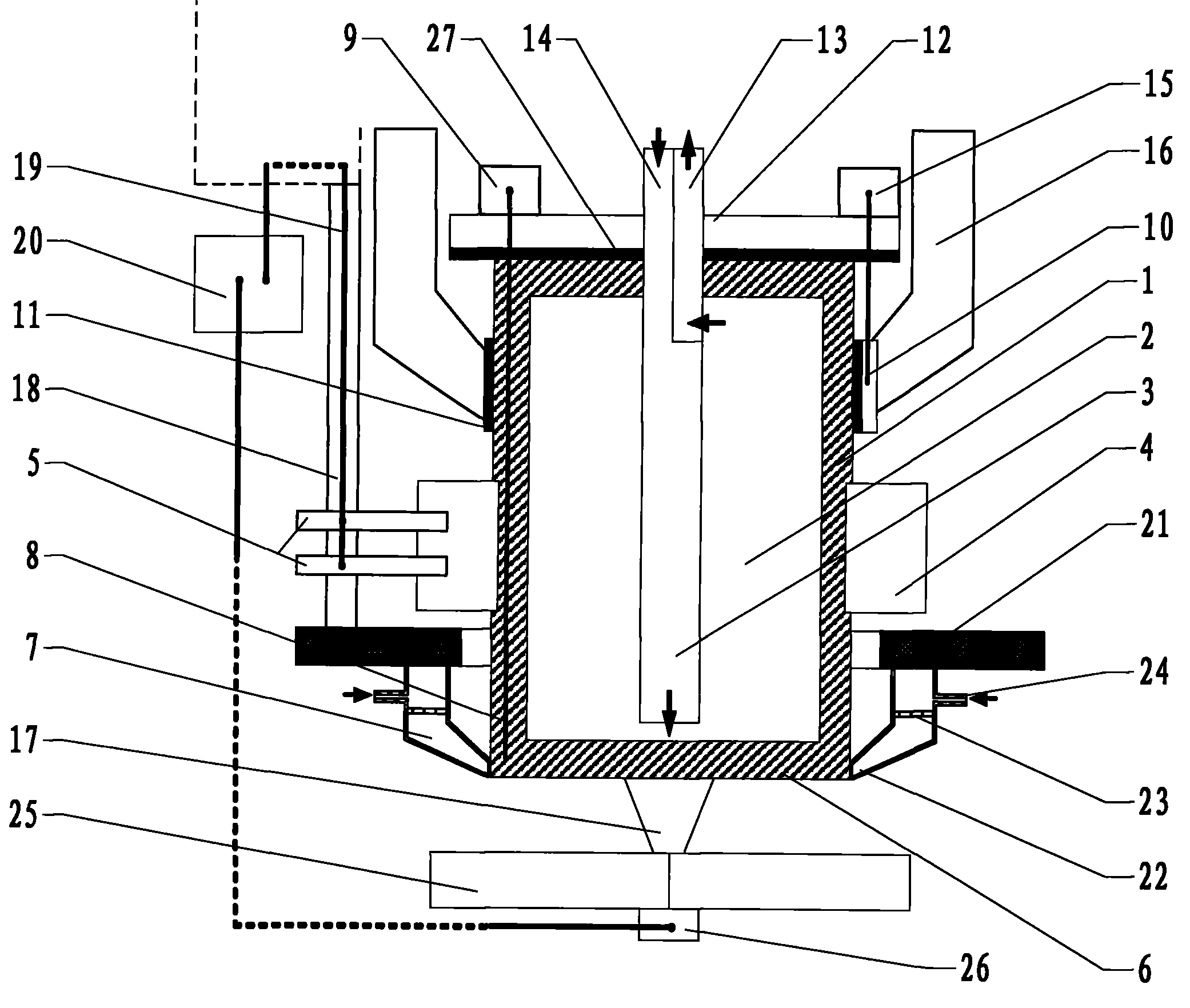

The invention discloses a pin tool used for friction stir welding and a current carrying friction stir welding method, wherein the pin tool comprises a pin tool body arranged on a friction welder and a tool pin arranged at the lower part of the pin tool body; the pin tool body is connected with the welder in a clamping way; the pin tool is characterized by being further provided with a forced cooling device, a current carrying device, a gas shielded device, a sensing device, sealing equipment and an insulating device. The invention has the advantages of high efficiency, low cost, high stability and excellent quality, breaks the limitation of conventional friction stir welding technology, overcomes the dependency of the pin tool for friction stir welding of the high melting point metal on high-quality materials and complex preparation technique, enriches the quality control methods of friction stir welding of the low melting point light alloy, realizes the effective and reasonable matching of high quality and low cost of friction stir welding and improves the friction stir welding technology, thus broadening the range of engineering application in the fields of solid phase welding and surface engineering.

Description

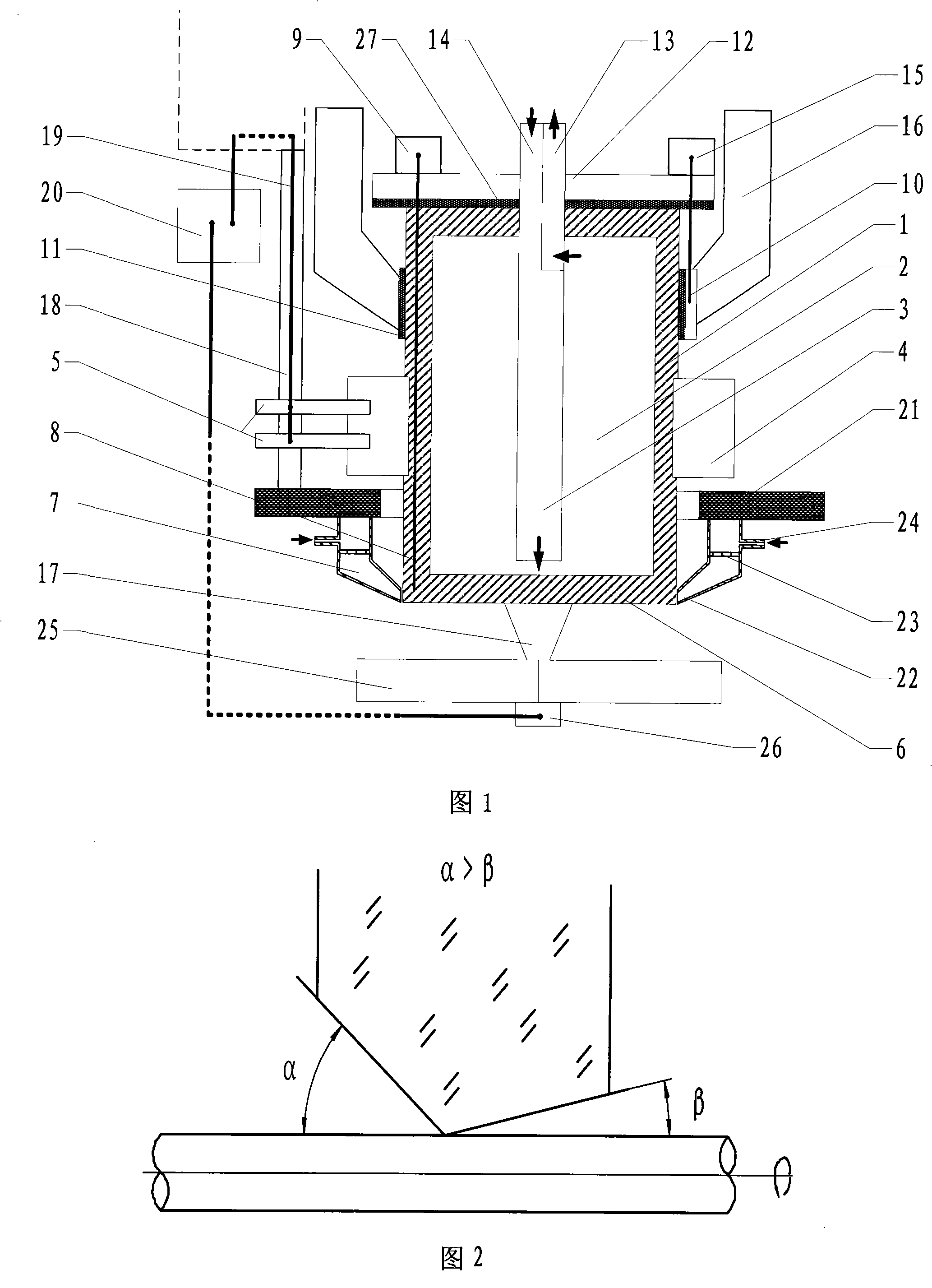

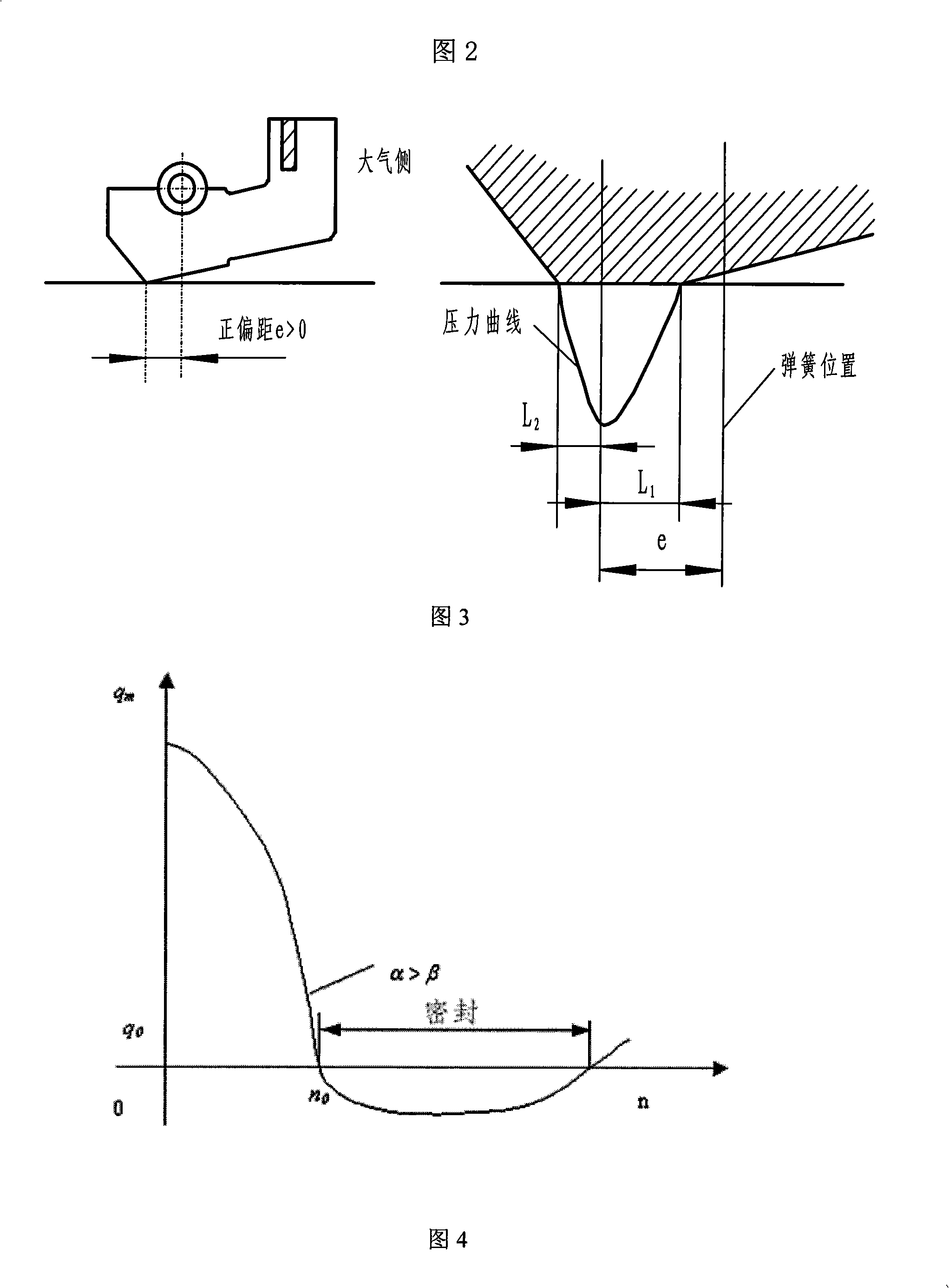

Stirring head for friction stir welding and current-carrying friction stir welding method technical field The invention relates to the field of welding technology, in particular to a stirring head of friction stir welding and a current-carrying friction stir welding method. Background technique In 1991, W.M.Thomas of the British Welding Institute (TWI) invented the friction stir welding technology and obtained a patent authorization in China (ZL95192193.2). The obvious superiority makes it one of the welding technologies that have been rapidly developed and widely used in engineering in the world in the past two decades. The industrial application of friction stir welding is mainly concentrated in the field of aluminum alloys. With the continuous expansion of its application fields, connecting objects and materials, friction stir welding technology has been successfully expanded in non-ferrous metals with low melting points. However, researchers have found that the applic...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): B23K28/02B23K20/12B23K11/00B23K20/26B23K20/14F16J15/32B23K35/38B23K20/24B23K20/22C21D7/13C22F1/00F16J15/3204

Inventor 罗键王颖

Owner CHONGQING UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com