Rotor for a flotation machine, method for forming same, and method for maintenance of same

A flotation machine and rotor technology, used in flotation, chemical instruments and methods, mixers, etc., can solve the problems of difficult and expensive handling, transportation and storage of heavy rotor parts, and reduce the cost of molding tools and molds. Small, easy to transport and store, low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

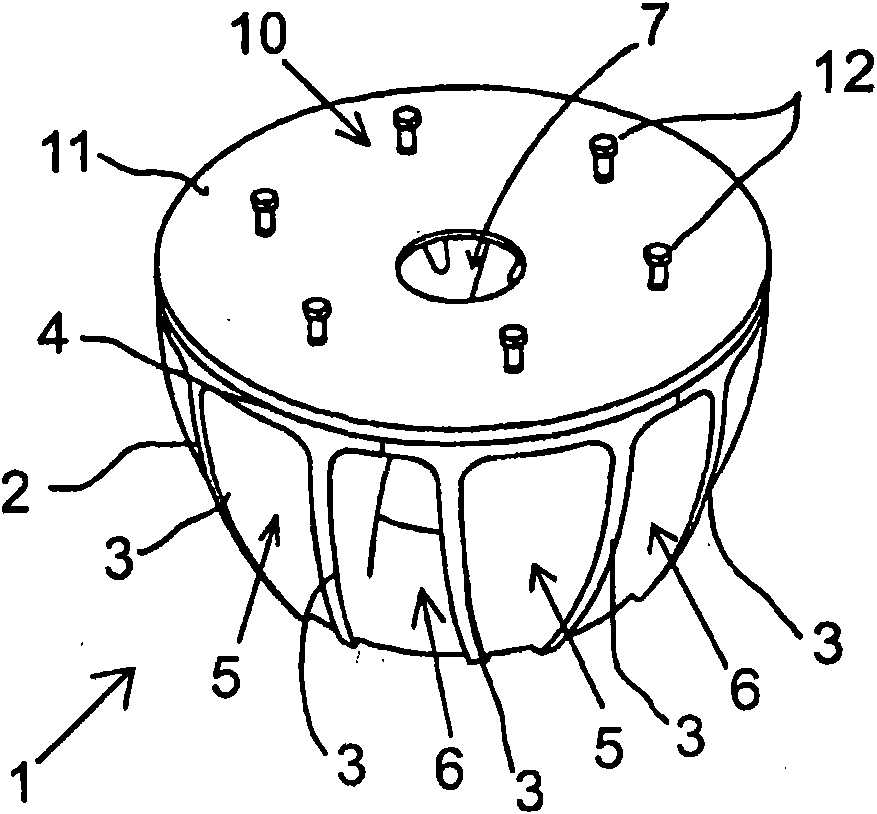

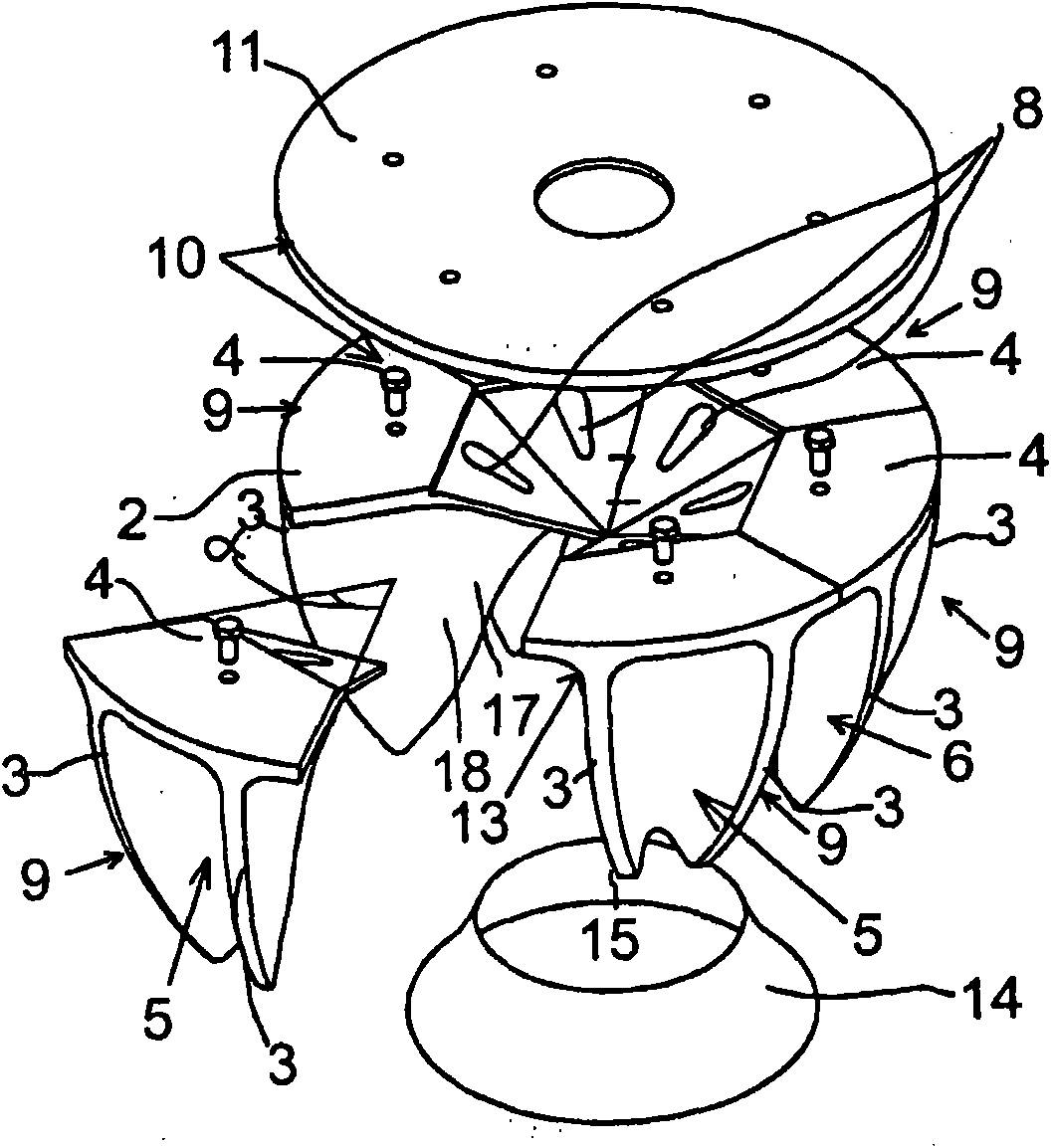

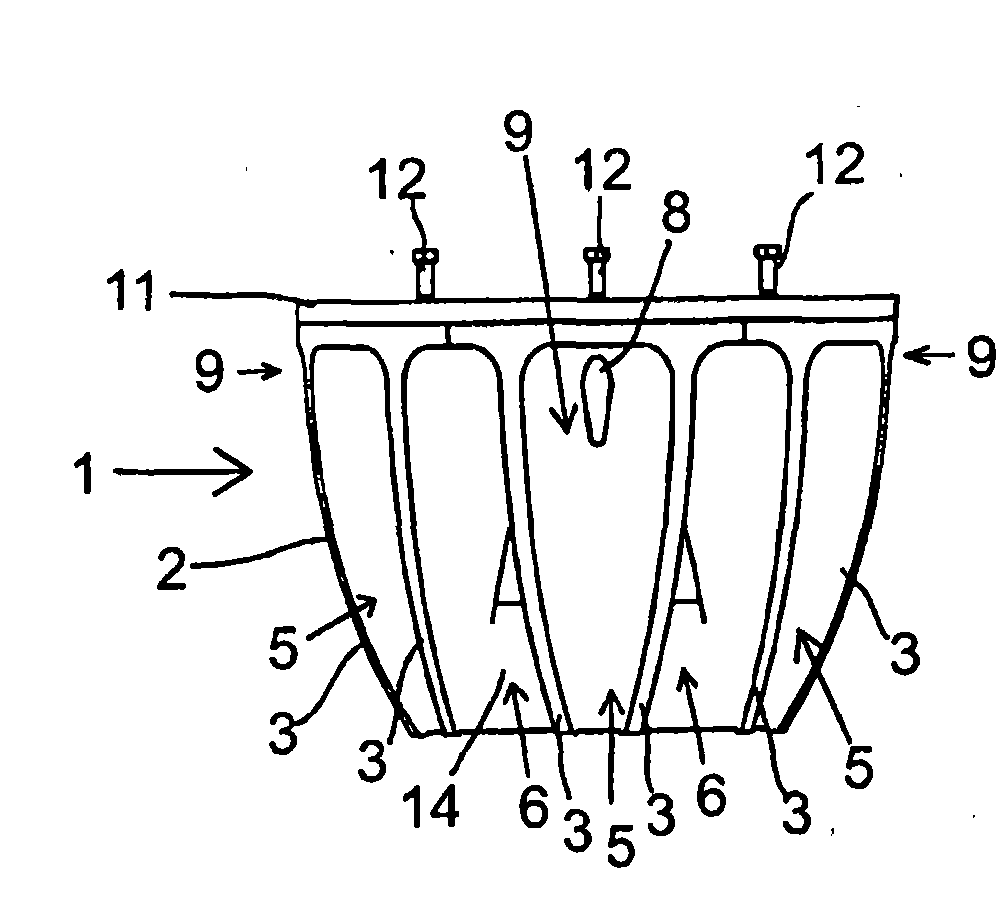

[0041] Figure 1-4 Shown is the rotor of the flotation machine used to disperse air into the sludge mixed with the rotor in the flotation cell (not shown). The rotor is fastened on a shaft (not shown). The rotor includes a cover flange 11 , a modular rotor body 2 and a bottom ring 14 , and the rotating shaft can be fastened on the cover flange 11 .

[0042] The rotor body 2 includes blades 3, in Figure 1-4There are 12 blades in the exemplary embodiment. The blades 3 extend radially outward with respect to the center of the rotor, and the blades 3 taper arcuately towards the lower end. The rotor body 2 also includes an upper wall 4 extending transversely (horizontally) relative to the blades 3 at the upper ends of the blades 3 so that blades adjacent to each other and parts of the upper wall 4 between these blades mutually Alternating radial air ducts 5 and slime ducts 6 are defined therebetween. Furthermore, the inclined portion of the upper wall 4 extending towards the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com