Method for programming the progress of an injection molding cycle of an injection molding machine

A technology for injection molding machines, processes, applied in program control, instrumentation, control/regulation systems, etc., to solve problems such as inability to test cycle segments without danger, tool damage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

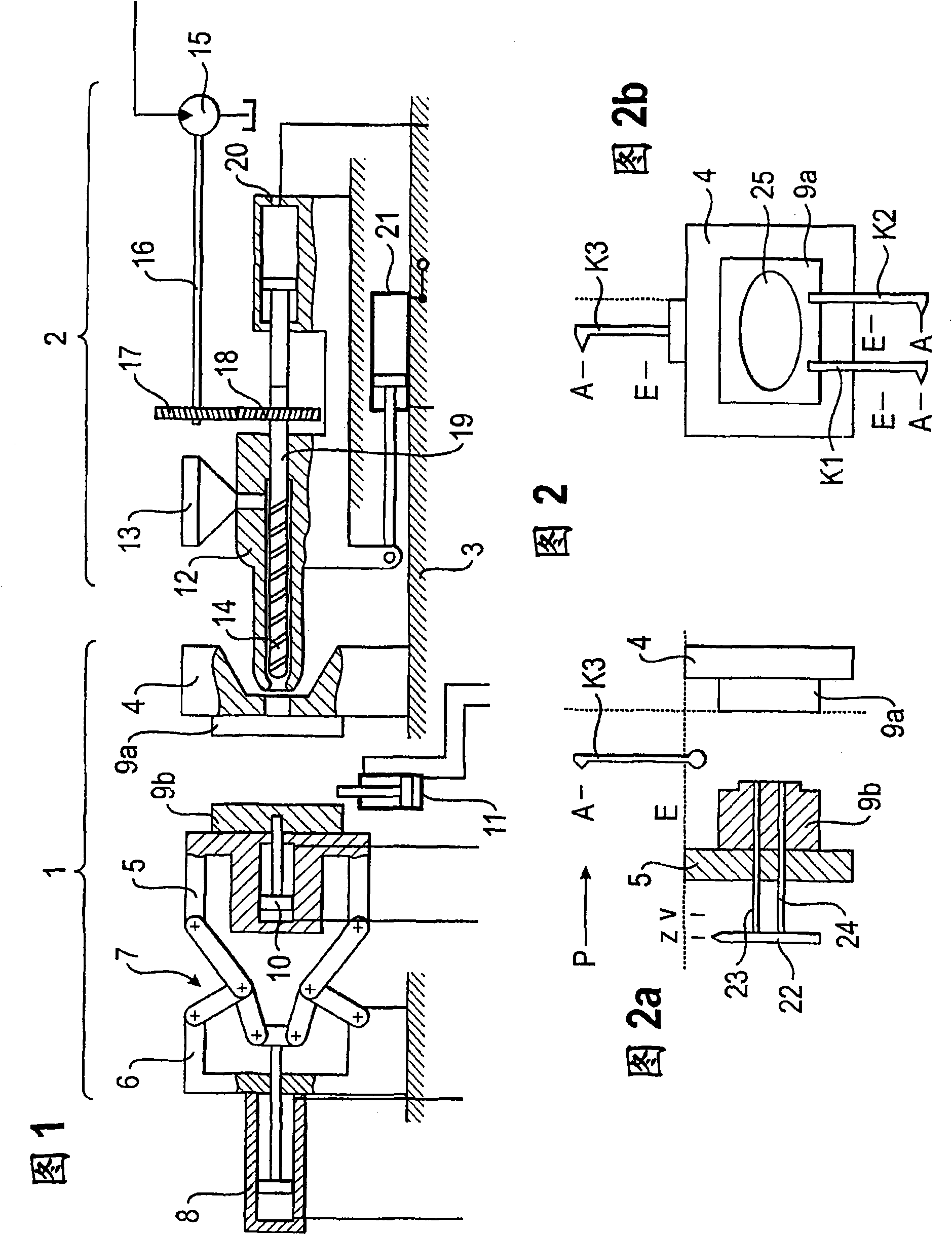

[0020] exist figure 1 The hydraulically driven injection molding machine shown schematically in , which is known per se, comprises a closing unit 1 and an injection unit 2 , which are carried by a frame 3 . The closing unit 1 comprises a fixed profiled fastening plate 4, a movable profiled fastening plate 5, a support plate 6, a crank mechanism 7 and a hydraulic cylinder 8 (closing cylinder) for operating the crank mechanism, wherein the profiled fastening plate 4 Having a fixed profiled half 9a, the profiled fastening plate 5 has a movable profiled half 9b. With this hydraulic cylinder 8 the movable profiled fastening plate 5 can be moved and the necessary closing pressure applied. It is also possible to move the movable profiled fastening plate on the one hand and to provide a separate hydraulic cylinder on the other hand for generating the required closing pressure. Furthermore, a hydraulic cylinder 10 is provided for operating the ejector and one or more hydraulic cylin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com