Antenna

An antenna and coil conductor technology, which is applied to antennas, helical antennas, antenna parts and other directions, can solve the problems of difficult to achieve miniaturization and high gain of the antenna, and the decrease of gain in the high frequency region, so as to reduce the attenuation loss and improve the gain. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

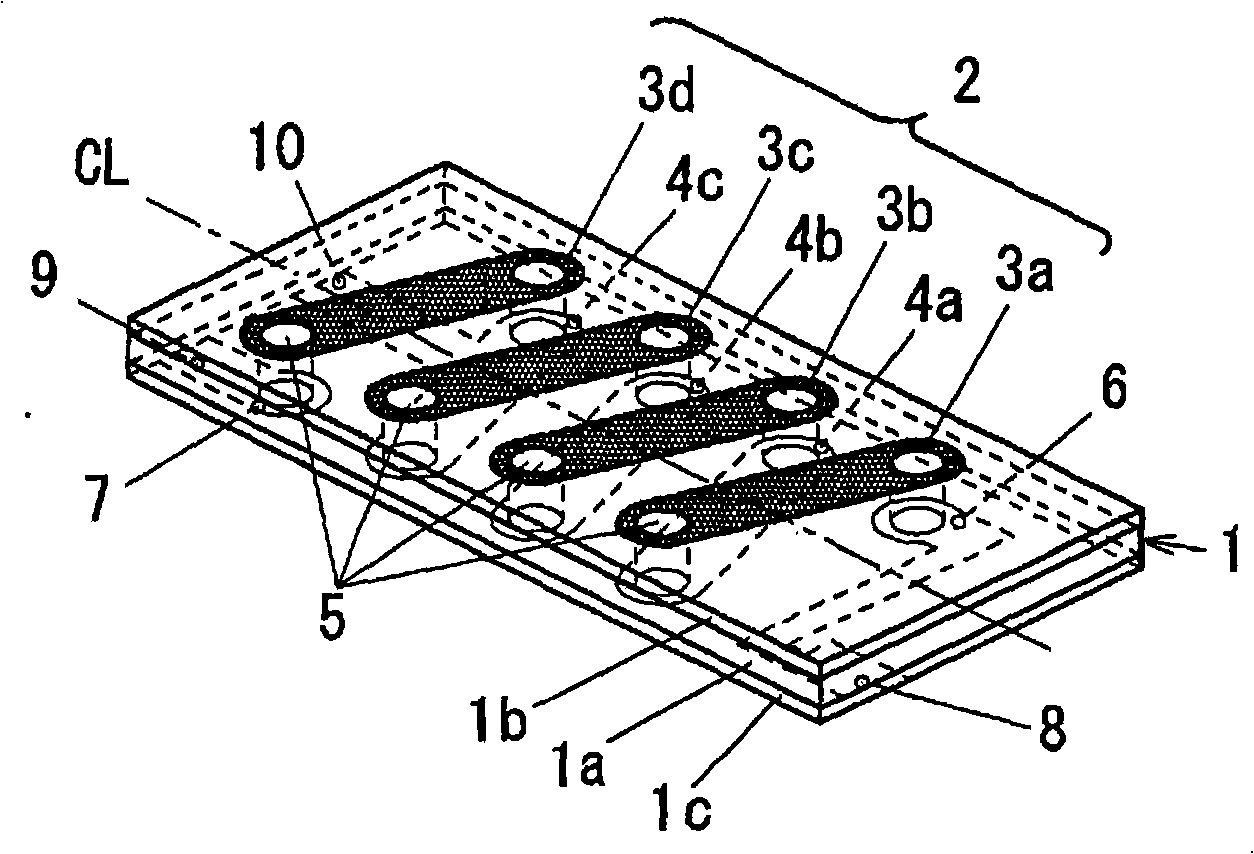

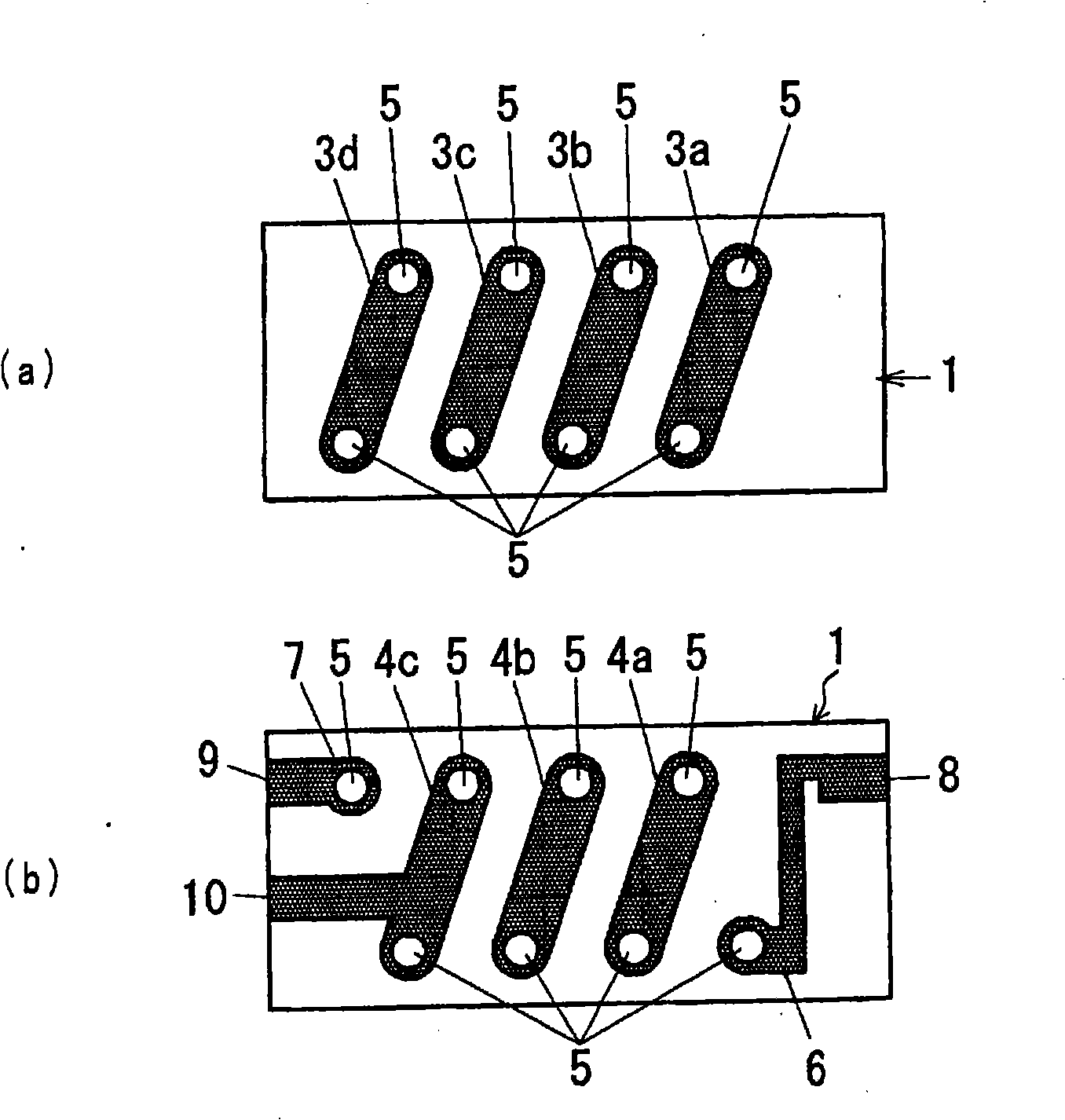

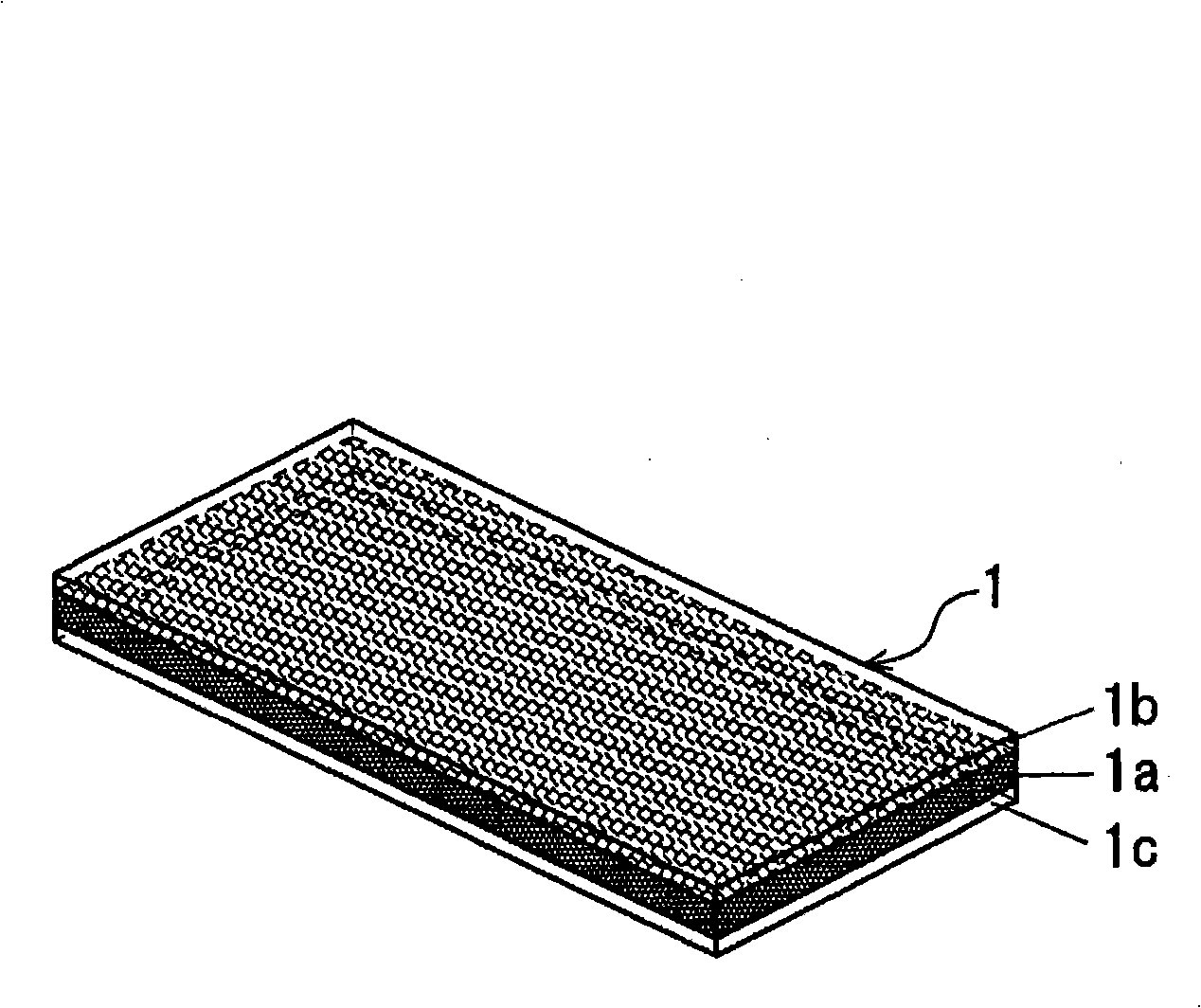

[0032] Figure 1 ~ Figure 3 The antenna structure of Embodiment 1 of the present invention is shown. figure 1 is the stereogram of the antenna, figure 2 is showing figure 1 The surface and back of the figure, figure 2 (a) showing the surface diagram, figure 2 (b) shows the back view. Reference numeral 1 is a magnetic core having a laminated structure formed such that a first resin layer 1a mixed with magnetic powder is provided at the center, and a second resin layer 1b and a third resin layer 1c not mixed with magnetic powder are sandwiched. The structure of the first resin layer 1a is maintained. The details of this magnetic core 1 will be described later.

[0033] Reference numeral 2 is a coil conductor, and constitutes the following conductor pattern. On the surface of the magnetic core 1, four conductor patterns 3a to 3d are formed as first conductor patterns. Each of the conductor patterns 3a to 3d is not parallel to the left and right sides of the magnetic co...

Embodiment 2

[0048] Next, Embodiment 2 of the antenna of the present invention will be described.

[0049] Figure 7 The structure of the magnetic core used in the antenna of Example 2 of the present invention is shown.

[0050] Figure 7 The illustrated magnetic core 1A has a constant thickness as a whole, but the thicknesses of the first, second, and third resin layers 1d, 1e, and 1f vary linearly. Specifically, the first resin layer 1d is set to be thin on the right end side of the magnetic core 1A, and the thicknesses of the second resin layer 1e and the third resin layer 1f are set to be thick. The thickness of the first resin layer 1d is set thicker on the left end side of the magnetic core 1A, and the thicknesses of the second resin layer 1e and the third resin layer 1f are set thinner. The thickness gradually changes from the right end side to the left end side of the core 1A in a linear form.

Embodiment 3

[0052] Next, Embodiment 3 of the antenna of the present invention will be described.

[0053] Figure 8 The structure of the magnetic core used in the antenna of Embodiment 3 of the present invention is shown.

[0054] Figure 8 The left half of the illustrated magnetic core 1B is a first core part 11 of a single-layer structure composed only of a resin layer 1g mixed with magnetic powder, and the right half is a second core part 12 of a laminated structure. The second magnetic core part 12 is formed of the following resin layers: a first resin layer 1h in which a resin layer mixed with magnetic powder is formed in the center of the right half; The second resin layer 1i formed of only resin and the third resin layer 1j formed of only resin.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com