Ground hydraulic augmented injection pump

A hydraulic and ground technology, used in pumps, piston pumps, liquid variable capacity machines, etc., can solve the problems affecting the service life of the booster pump, the inability to fine-tune the water pressure, and the troublesome replacement of the water distributor. The effect of reducing water impurities and prolonging life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

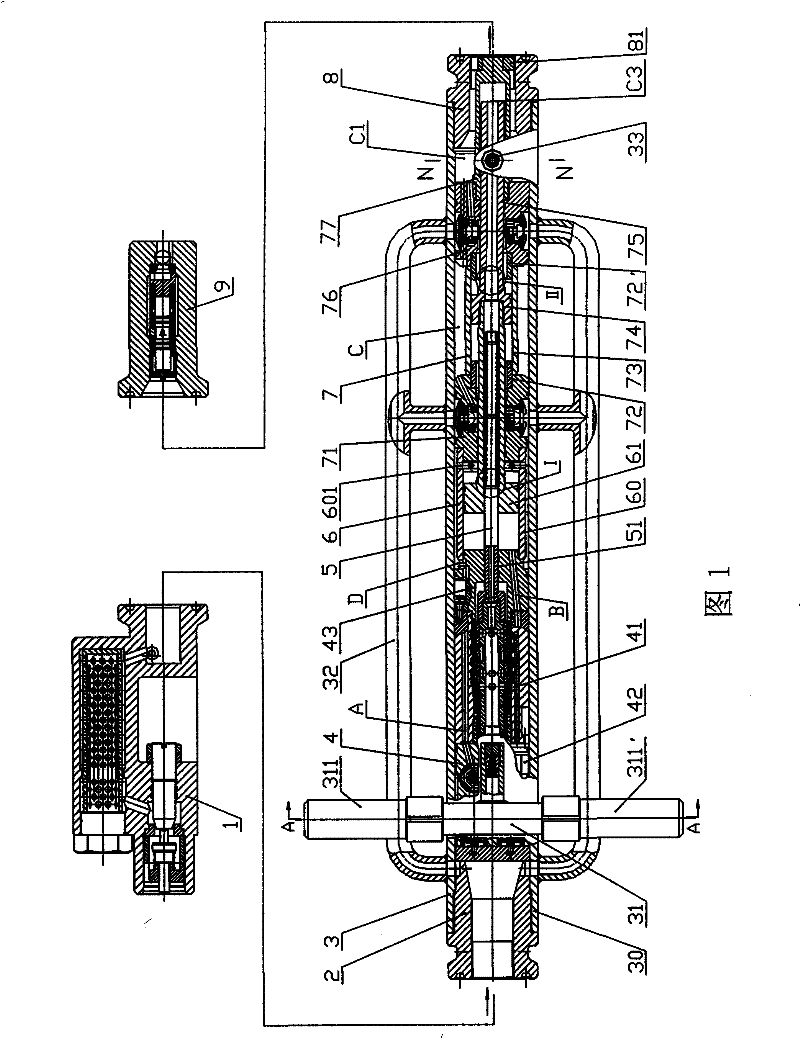

[0125] Such as figure 1 As shown, the ground hydraulic injection pump is mainly composed of an inlet filter decompression device 1, a water inlet joint of the pump station pipe network (left joint for short) 2, a pump main body 3, a boost outlet joint 8 (right joint for short) and a boost outlet The water distribution joint 9 is formed; the pump main body 3 includes a housing main body 30 and a reversing valve 4, a reversing control device 5, a power cylinder 6 and a booster that are arranged in the housing main body 30 and arranged sequentially and coaxially along the axis of the housing main body 30. Pressure cylinder 7; the right end of the inlet filter decompression device 1 is connected with the left joint 2 with a clamp (not shown in the figure), and the right end of the left joint 2 is threaded and sealed with the housing main body 30; the left end of the right joint 8 is connected with the housing The main body 30 is threaded and sealed, and the right end of the right ...

Embodiment 2

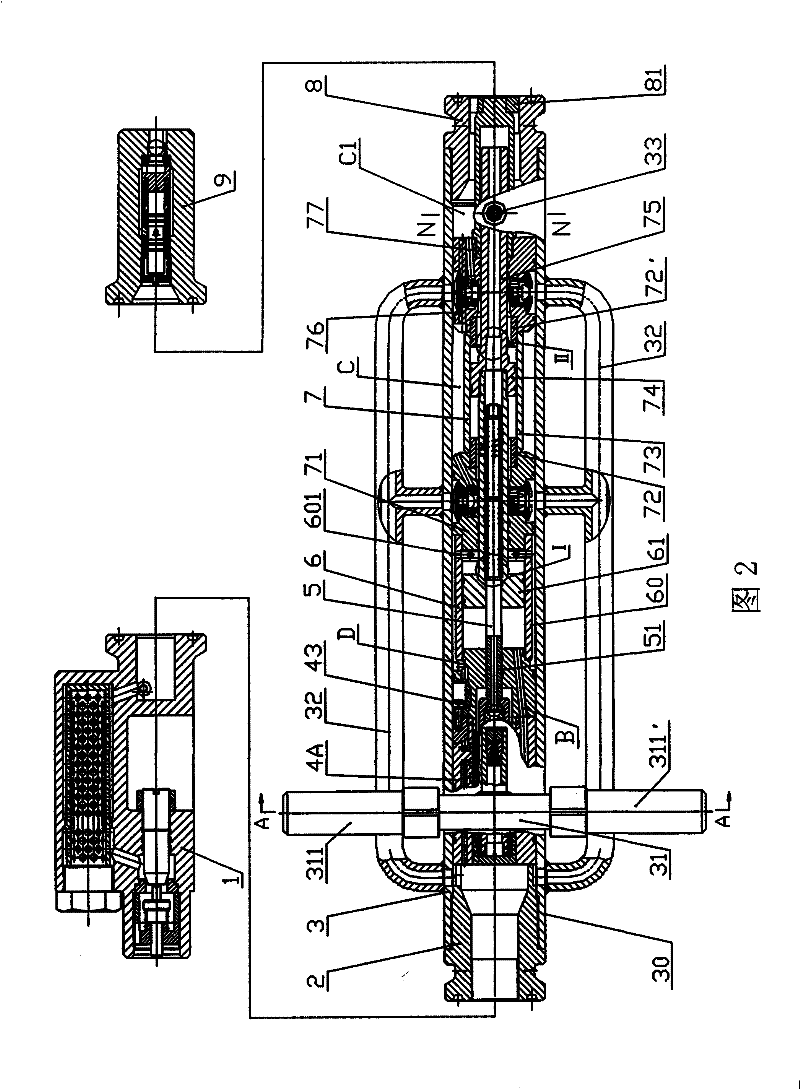

[0140] Such as figure 2 , Figure 18 and Figure 20 As shown, the surface injection pump of this embodiment is mainly composed of an inlet filter decompression device 1, a pump station pipe network water inlet joint (left joint for short) 2, a pump main body 3, a pressurized outlet joint 8 (right joint for short) and a booster The pressure outlet water distribution joint 9 is formed; the pump main body 3 includes a housing main body 30 and a reversing valve 4A, a reversing control device 5, a power cylinder 6 and a booster that are arranged in the housing main body 30 and arranged in sequence along its axis and coaxially. Pressure cylinder 7; the right end of the inlet filter decompression device 1 is connected with the left joint 2 with a clamp (not shown in the figure), and the right end of the left joint 2 is threaded and sealed with the housing main body 30; the right joint 8 is connected with the housing main body 30 is threaded and sealed, the right end of the right j...

Embodiment 3

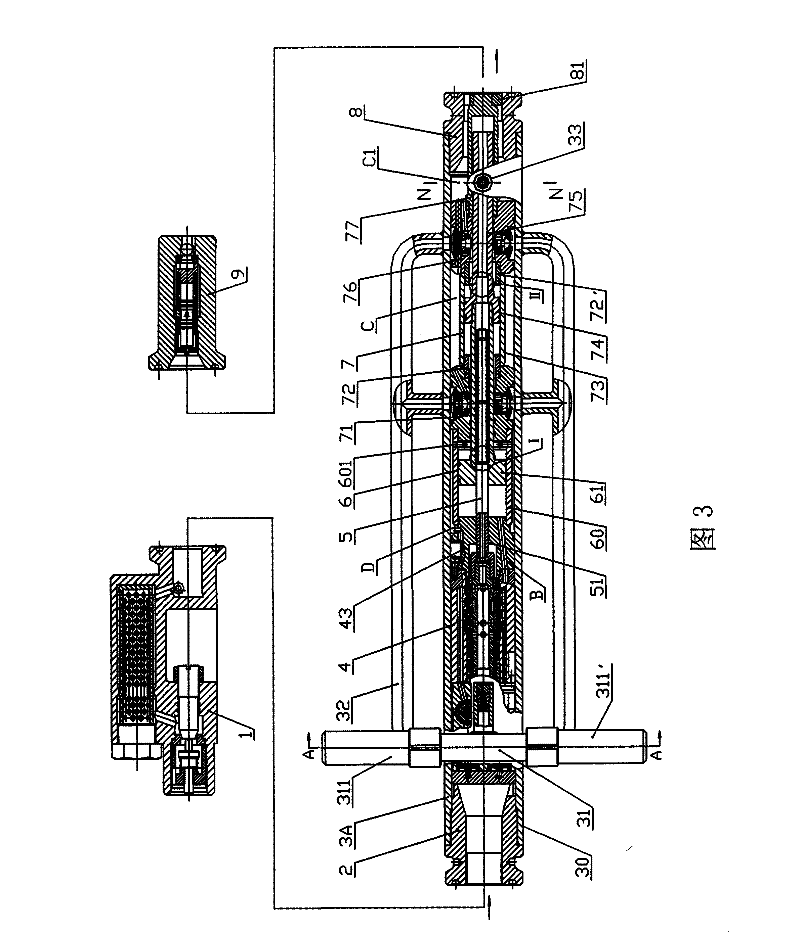

[0144] Such as image 3 As shown, the ground injection pump of this embodiment is mainly composed of an inlet filter decompression device 1, a water inlet joint of the pump station pipe network (abbreviated as the left joint) 2, a pump main body 3A, a pressurized outlet joint 8 (abbreviated as the right joint) and an increaser The pressure outlet water distribution joint 9 is formed; the pump main body 3A includes a housing main body 30 and a reversing valve 4, a reversing control device 5, a power cylinder 6 and a booster that are arranged in the housing main body 30 and arranged in sequence along its axis and coaxially. Pressure cylinder 7; the right end of the inlet filter decompression device 1 is connected with the left joint 2 with a clamp (not shown in the figure), and the right end of the left joint 2 is threaded and sealed with the housing main body 30; the right joint 8 is connected with the housing main body 30 is threaded and sealed, the right end of the right join...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com