Self cleaning filter assembly and circulation system

A filter assembly, self-cleaning technology, applied in the field of self-cleaning filter assemblies, can solve problems such as increased fire risk, danger, and bulkiness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

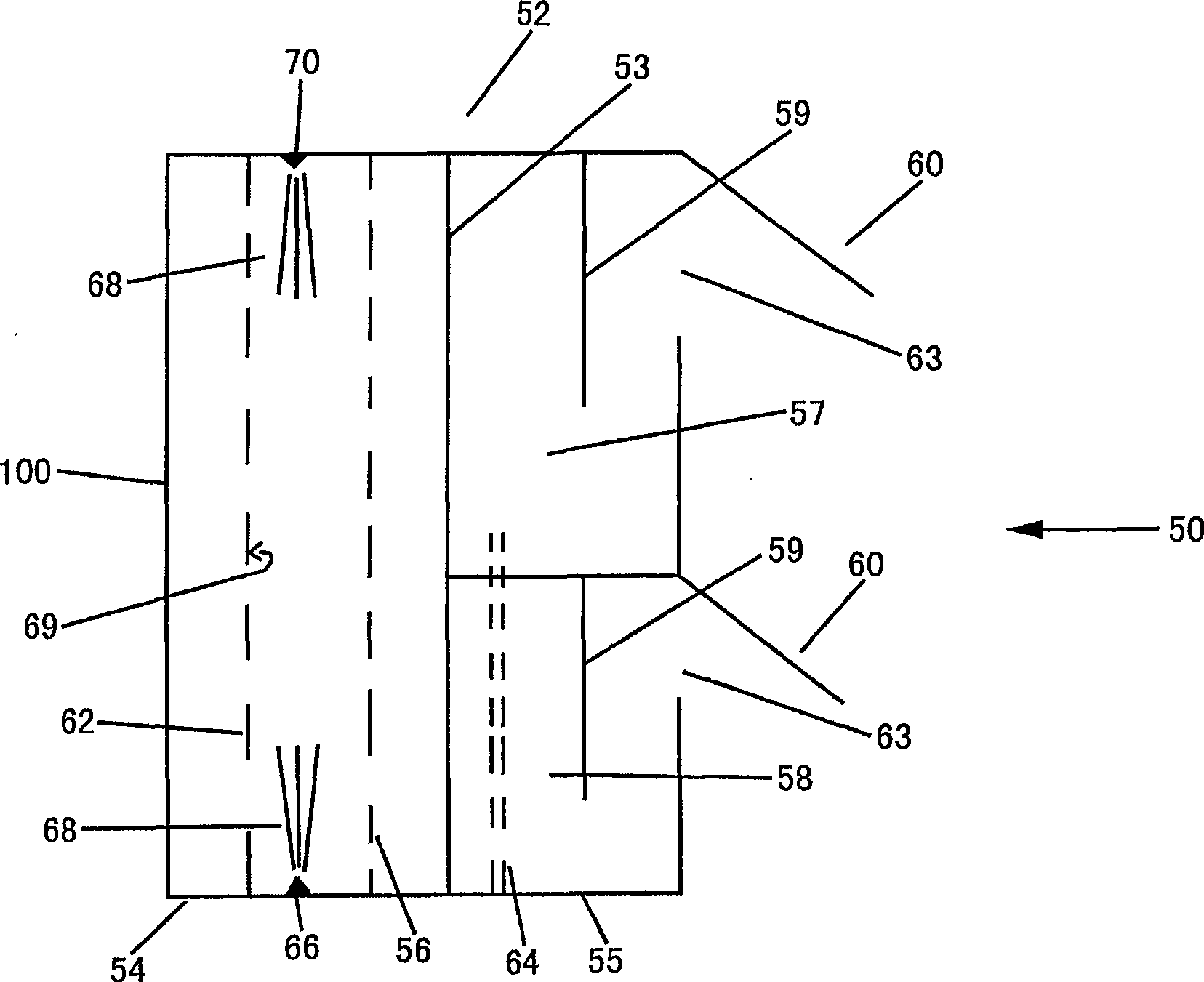

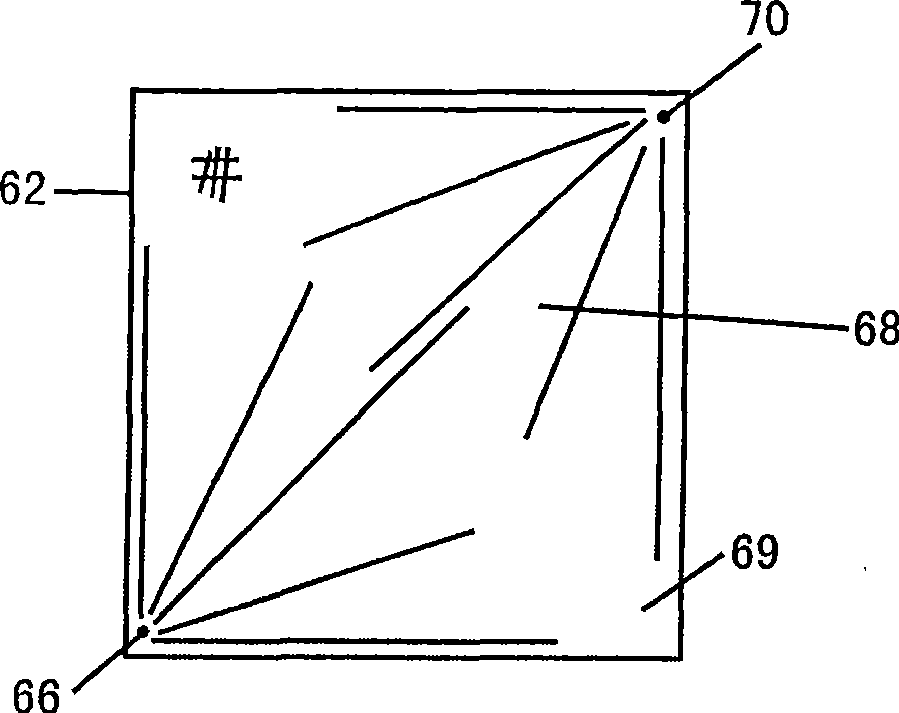

[0034] First refer to figure 1 , shows an air flow passage through the exhaust system, with air flowing in the direction of arrow 50 . The air passing in the direction of arrow 50 may contain contaminants such as oil droplets, dust, particulate matter and others. Air is drawn in the direction of arrow 50 when an exhaust fan (not shown) of the exhaust system operates.

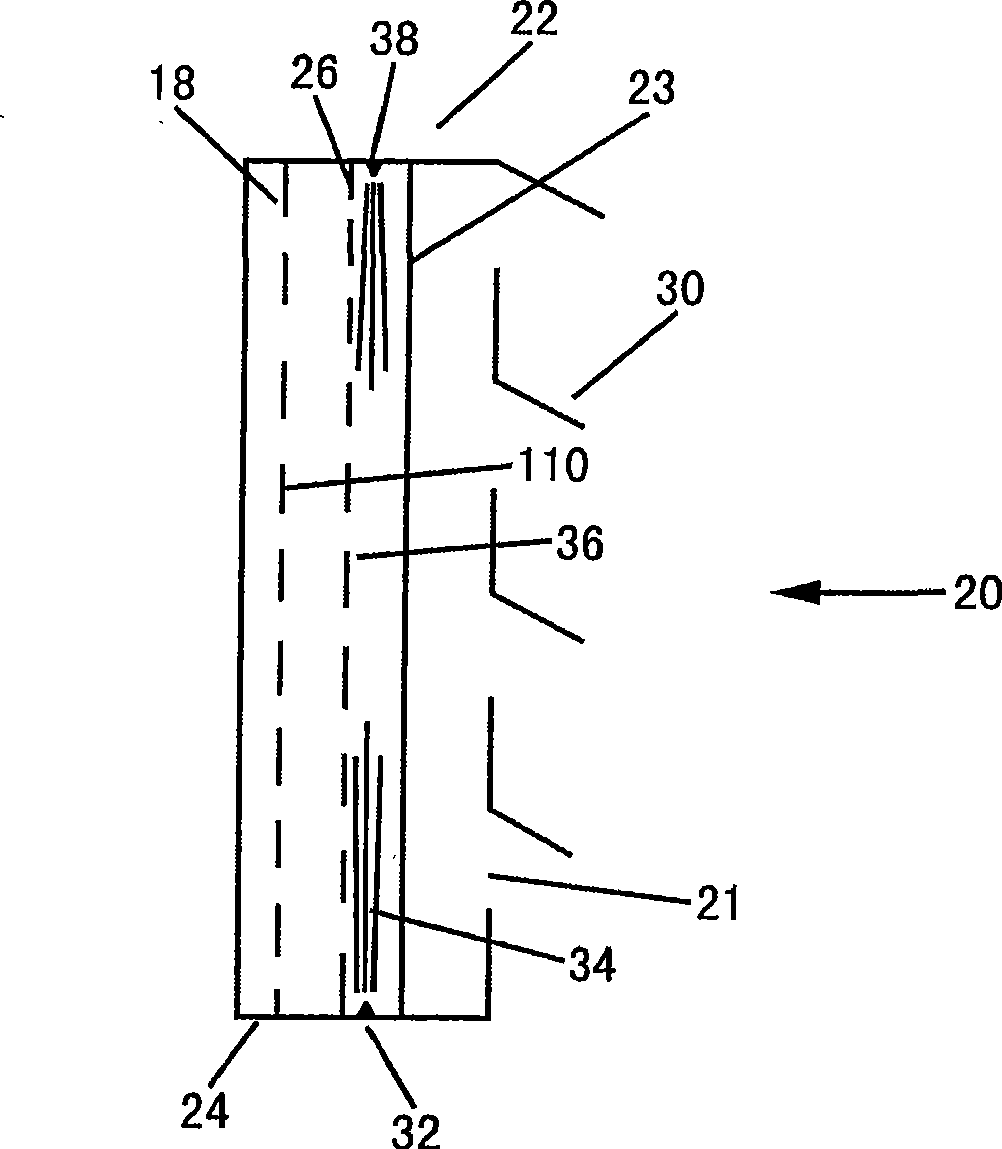

[0035] The self-cleaning filter assembly 52 is arranged in the airflow channel of the exhaust system along the airflow direction 50 . Self-cleaning filter assemblies fit into brackets or slots on existing filter assemblies in existing exhaust systems. Existing baffle filters may be replaced with self-cleaning filter assemblies 52 . A traditional kitchen exhaust system can be replaced with an advanced grease removal kitchen exhaust system with minimal capital expenditure. Such as Figure 14 As shown, the self-cleaning filter assembly 52 may be installed in an existing bracket or slot in an existing exhaust s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com