Spray nozzle manifold and process for quenching a hot gas using such an arrangement

一种高温气体、喷嘴的技术,应用在高温气体骤冷领域,能够解决喷雾嘴堵塞等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

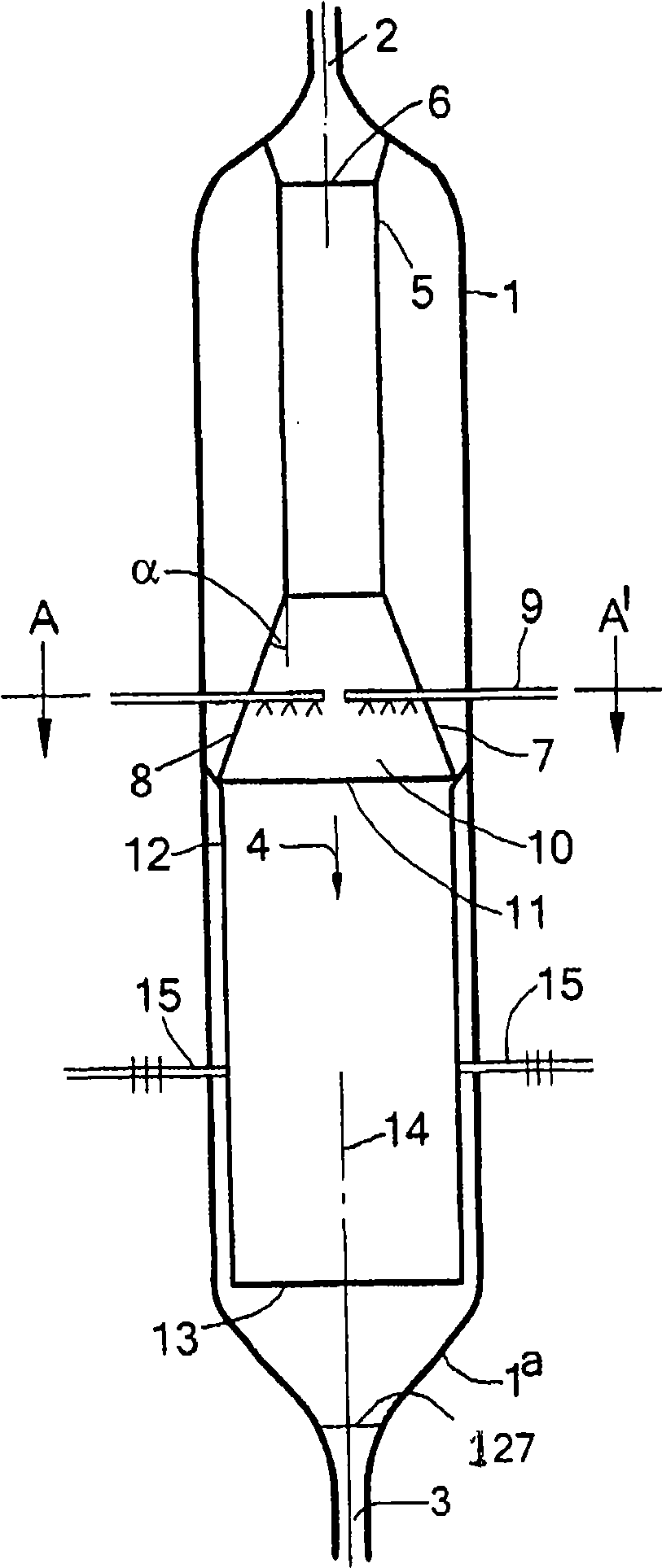

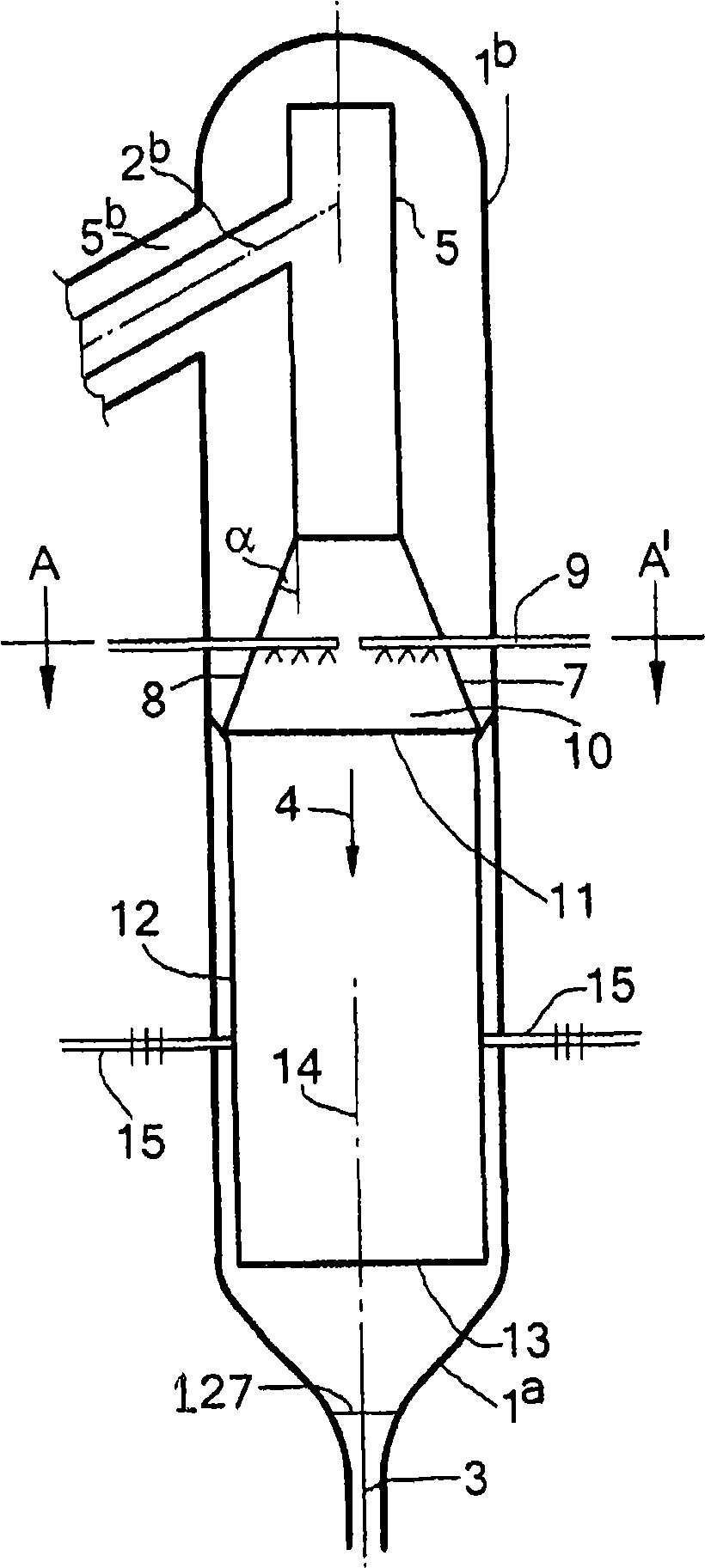

[0012] Define nozzle manifolds using terms such as upper, top, lower, down, horizontal, vertical. These terms refer to nozzle manifolds in such Figure 1-4 Preferred orientation for use shown. These terms are not used to limit the scope of the invention to nozzle manifolds having only this orientation.

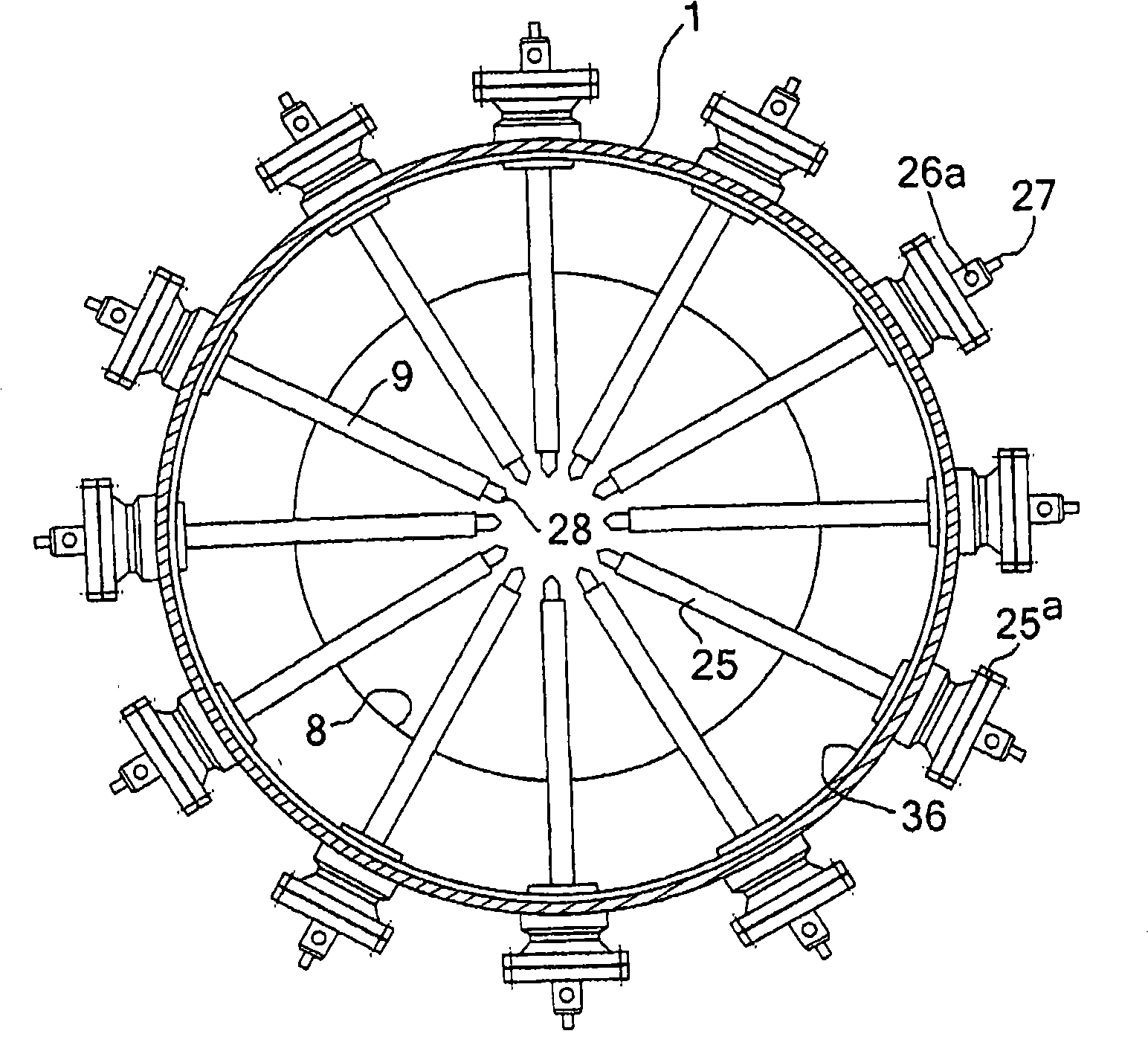

[0013] The nozzle manifold according to the invention has a first coaxial channel for supplying atomizing gas and a second coaxial channel present in said first channel for supplying liquid. These channels are preferably tubular. Transversely spaced nozzles are positioned to atomize and eject the liquid in a direction away from the longitudinal axis of the manifold. Preferably, the nozzles are positioned on a line parallel to the longitudinal axis. Preferably, the nozzles are positioned to spray in the same direction perpendicular to the longitudinal axis, spaced apart from additional nozzles positioned at the end of the channel, which may spray in a different direction, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com