Anti-spattering bow fin of high-speed ship

An anti-splash and high-speed technology, which is applied in the field of ship fin device and hull structure of high-speed ships, can solve the problems of increasing manufacturing and use costs, and achieve the effect of reducing energy loss of the first wave and suppressing splash flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below with reference to the drawings and embodiments.

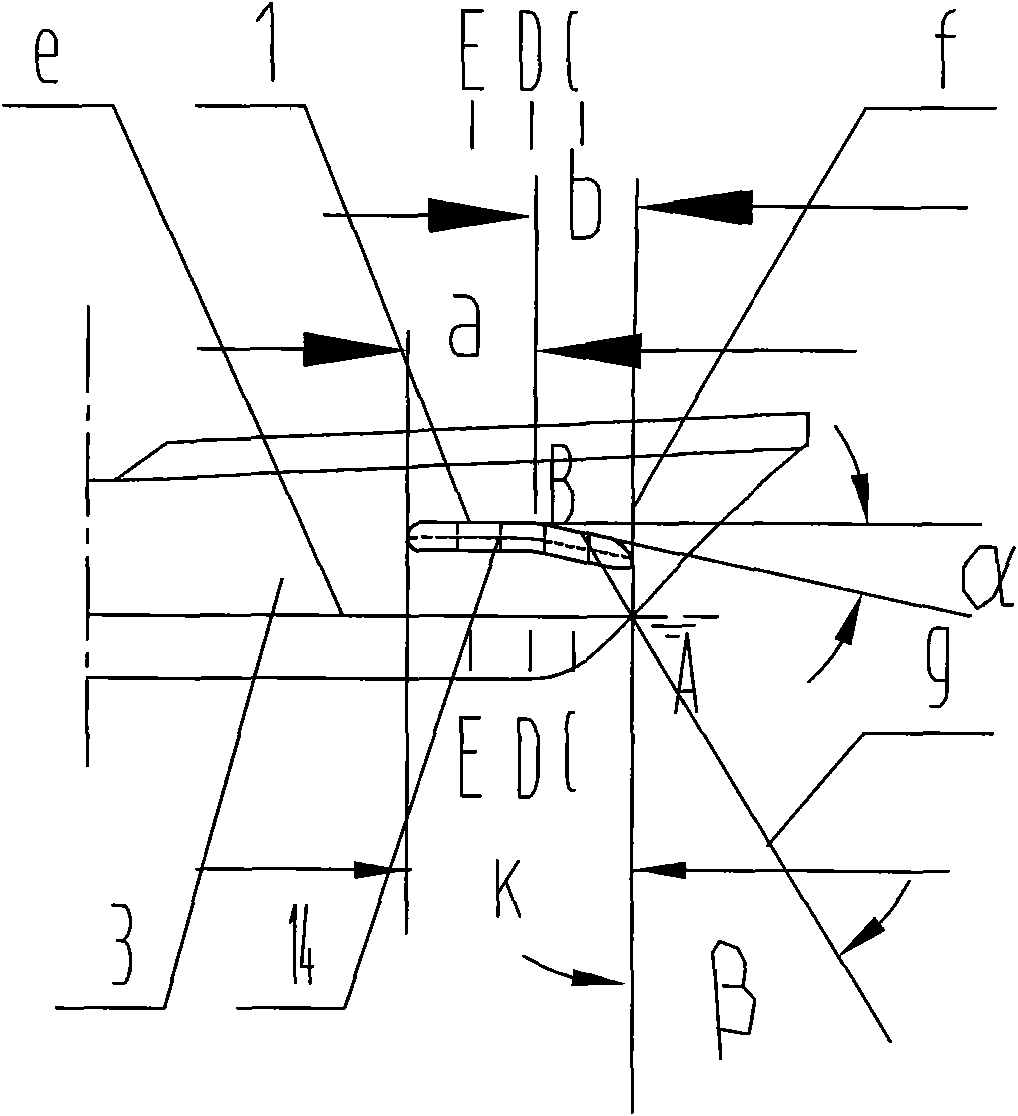

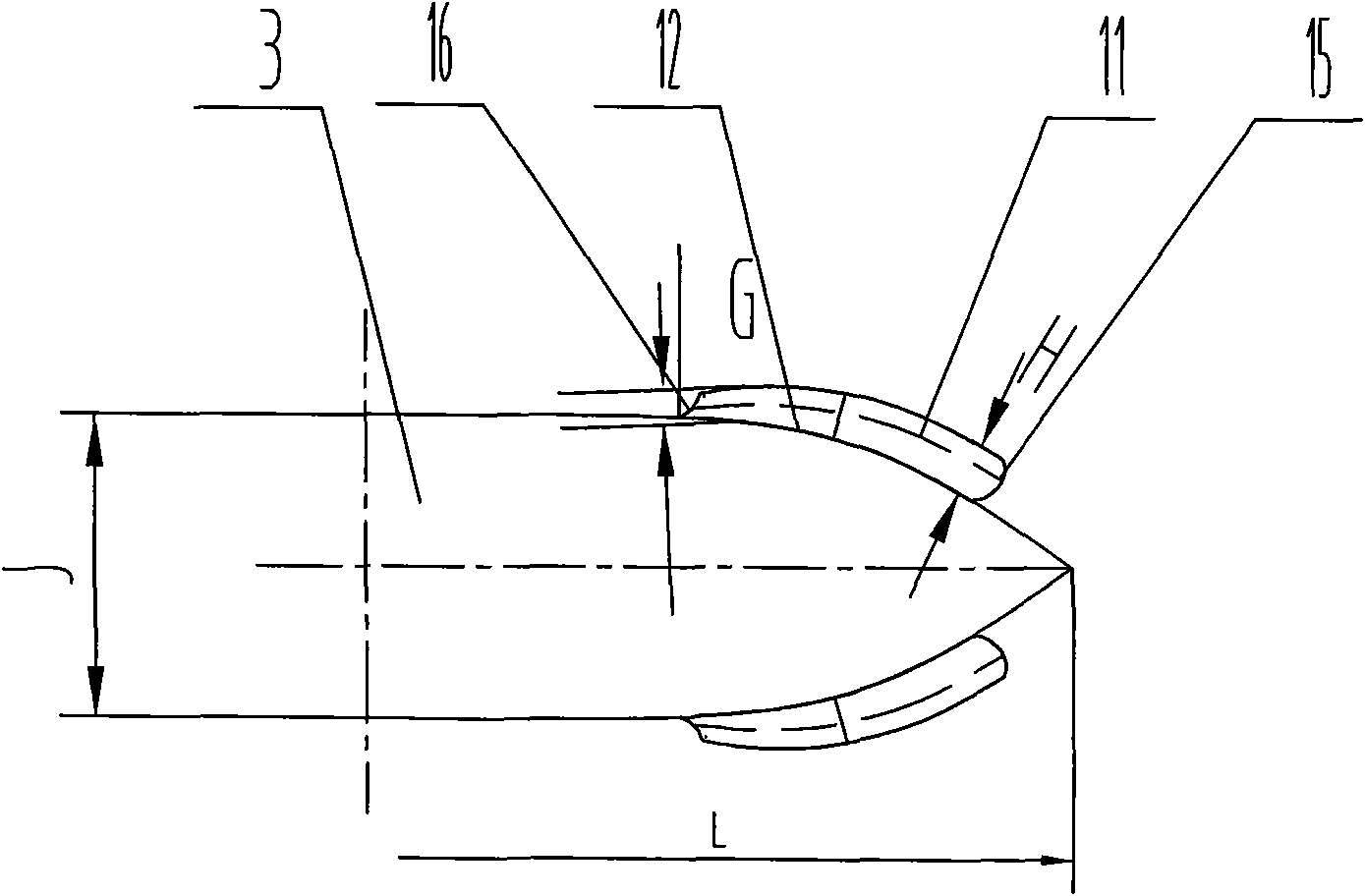

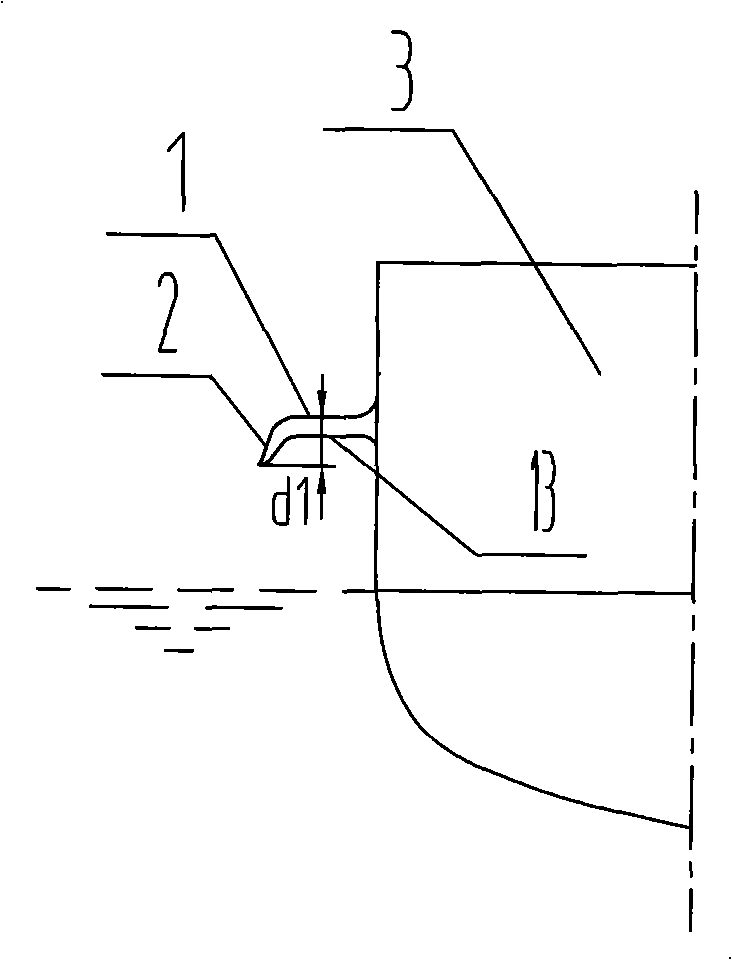

[0027] Such as Figure 1 ~ Figure 6 As shown, the present invention is arranged on both sides above the waterline of the bow of a high-speed ship. The longitudinal view of the present invention is a streamlined structure of a closed wing. The closed wing is close to the bow and the waterline is 8°-25° The angle α, away from the bow, is parallel to the waterline surface e, and the closed wing is formed by smoothly connecting and welding the upper plate I11 at an angle with the waterline surface α and the upper plate II 12 and the lower plate 13 parallel to the waterline surface. The longitudinal streamlined closed wing of the present invention is provided with four transverse support ribs 14 at certain intervals to improve the structural strength and rigidity of the closed wing. The transverse view of the present invention is a streamlined closed wing bent down from the ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com