Method of establishing damnification self-diagnosis system for carbon fiber enhancement resin base composite material

A resin-based, self-diagnostic system technology that is applied in the direction of testing material strength and material resistance using a single impact force, testing material strength using a stable bending force, etc., can solve the problem of not being able to intuitively reflect the status of materials and not building composite materials Damage self-diagnosis system and other issues to achieve accurate diagnosis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

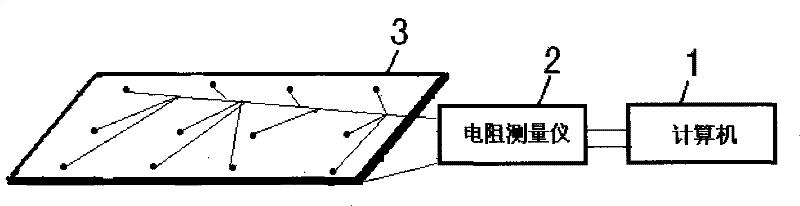

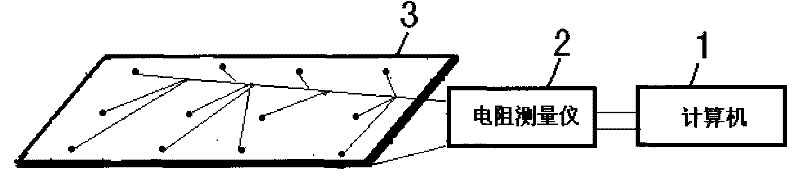

[0017] Such as figure 1 Shown, the present invention is realized like this, and method step is: (1) composite material 3 adopts commercialization (G803 / 5224) carbon fiber cloth / epoxy resin prepreg as raw material, lays up (8 layers) according to warp direction ), and arrange tiny copper sheet electrodes (diameter 6mm, thickness 0.2mm, half of the electrode is exposed on the surface of the material) between the 1st and 2nd layers in a matrix equidistant (60mm spacing), and then put them into a hot press for curing and molding , to prepare a composite material sheet, the thickness of the sheet is about 2.0mm, and the volume content of carbon fiber is about 70%. Remove the burrs and flying burrs, cut the plate into a sample with a length*width of 200mm*150mm, polish the surface of each copper sheet electrode with fine sandpaper, and solder the wires with solder, connect the resistance measuring instrument 2 and the computer 1, and pass the resistance measuring instrument 2 Measu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com