Sucker controller

A controller and sucker technology, which is applied in the direction of magnetic objects, electrical components, load suspension components, etc., can solve the problems of complex demagnetization circuit and long demagnetization time, and achieve the effect of simple demagnetization circuit, fast demagnetization speed and low failure rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

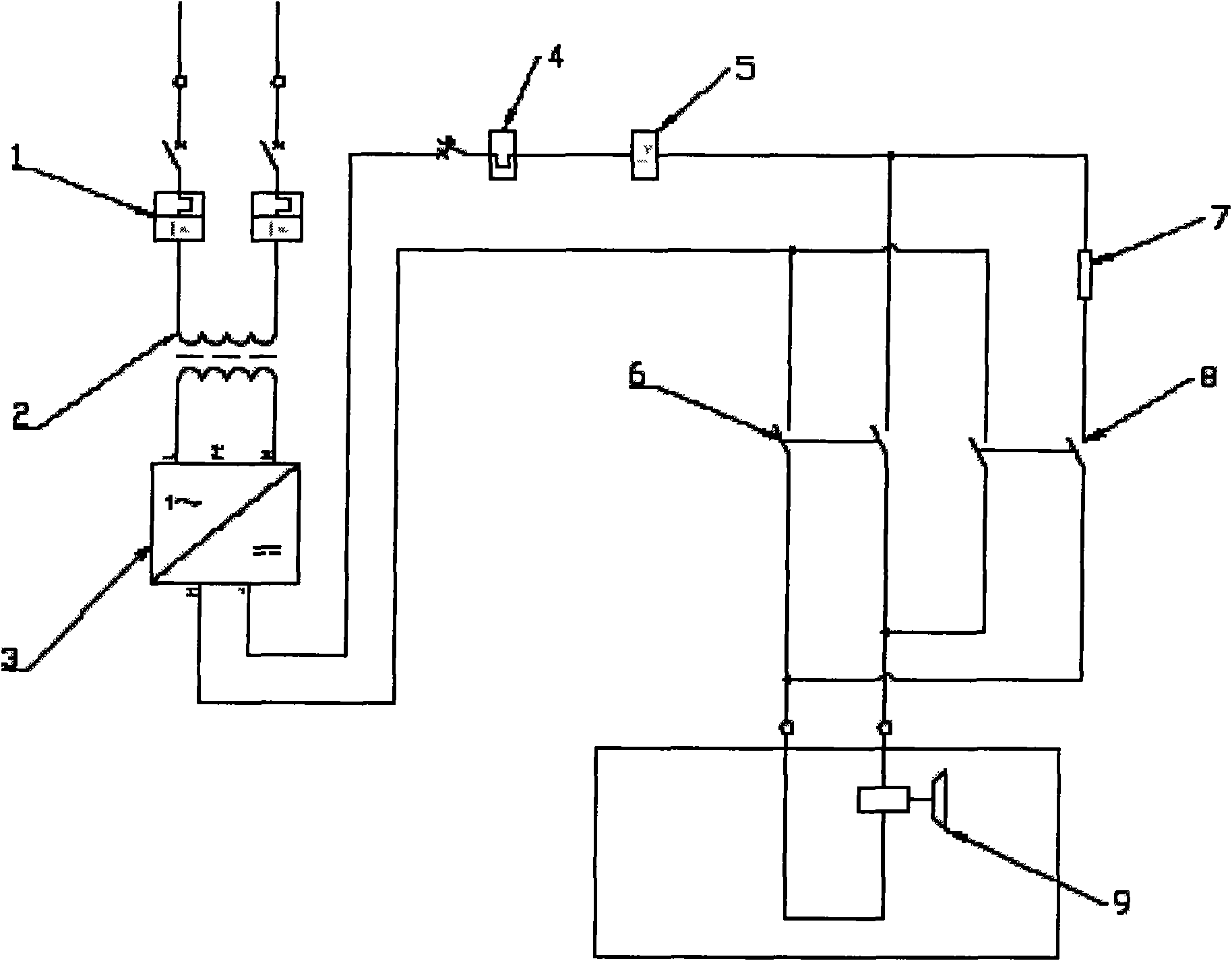

[0010] exist figure 1 Among them, a sucker controller consists of an air switch (1), a transformer (2), a rectifier (3), an air switch (4), a current relay (5), a magnetism relay (6), a demagnetization resistor (7) and Composed of demagnetization relay (8), the air switch (1) is connected in series with the primary side of the transformer (2), after the secondary side of the transformer is connected in series with the rectifier (3), it is connected in series with the air switch (4) and the current relay (5), and then connected with the The demagnetization relay (6) is connected in series with the demagnetization circuit in parallel, and finally connected with the sucker (9); in the demagnetization circuit, the demagnetization resistor (7) is connected in series with the demagnetization relay (8).

[0011] Working principle: When magnetically absorbing, the transformer (2) transforms the input voltage, rectifies it into direct current through the rectifier (3), and then adds it...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com