Special fixture for manufacturing process of semiconductor module and sliding block component thereof

A manufacturing process and special fixture technology, applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve problems such as increased manufacturing costs, easy drop of workpieces, and poor return function of steel springs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Hereinafter, embodiments of the present invention will be described in detail with reference to the drawings.

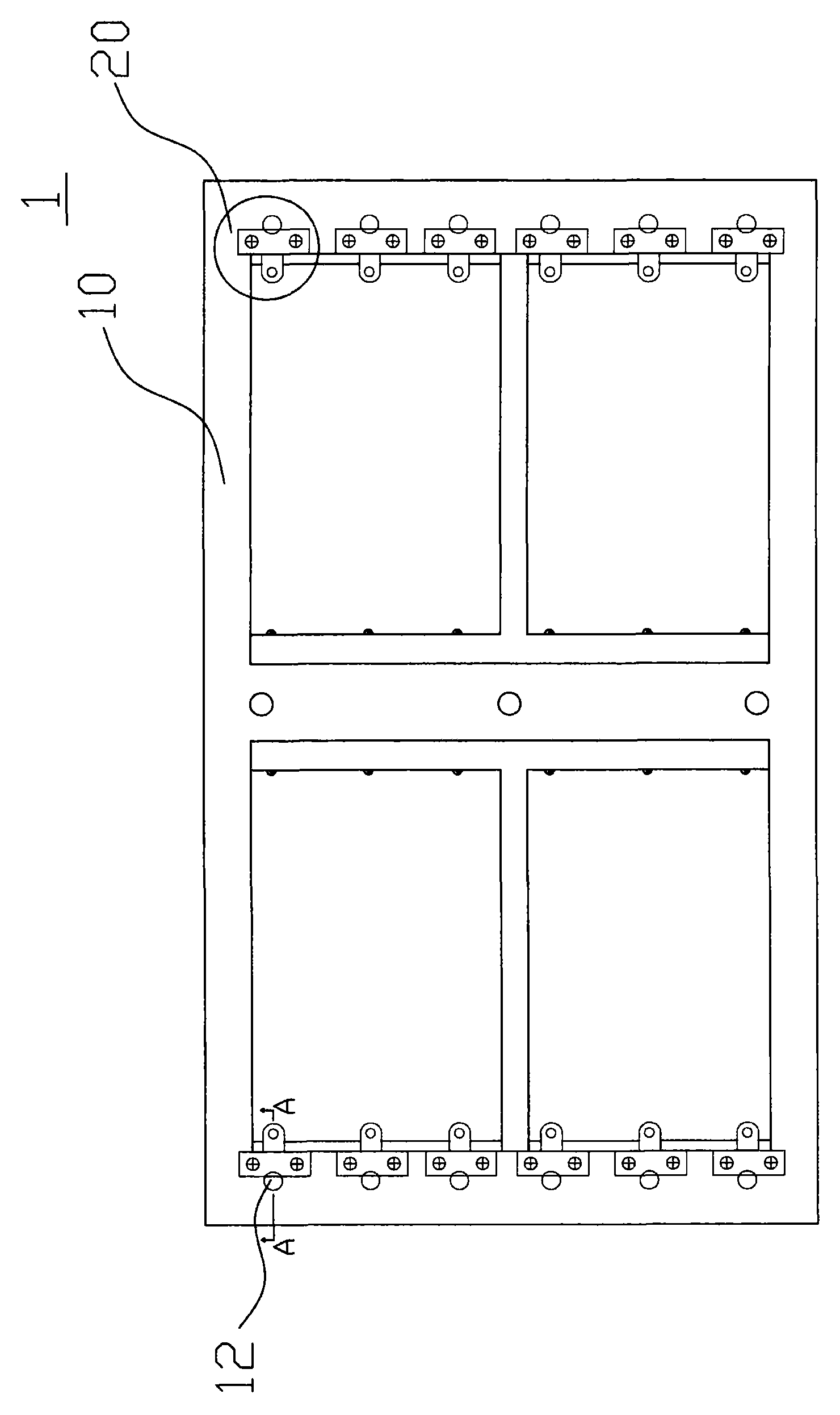

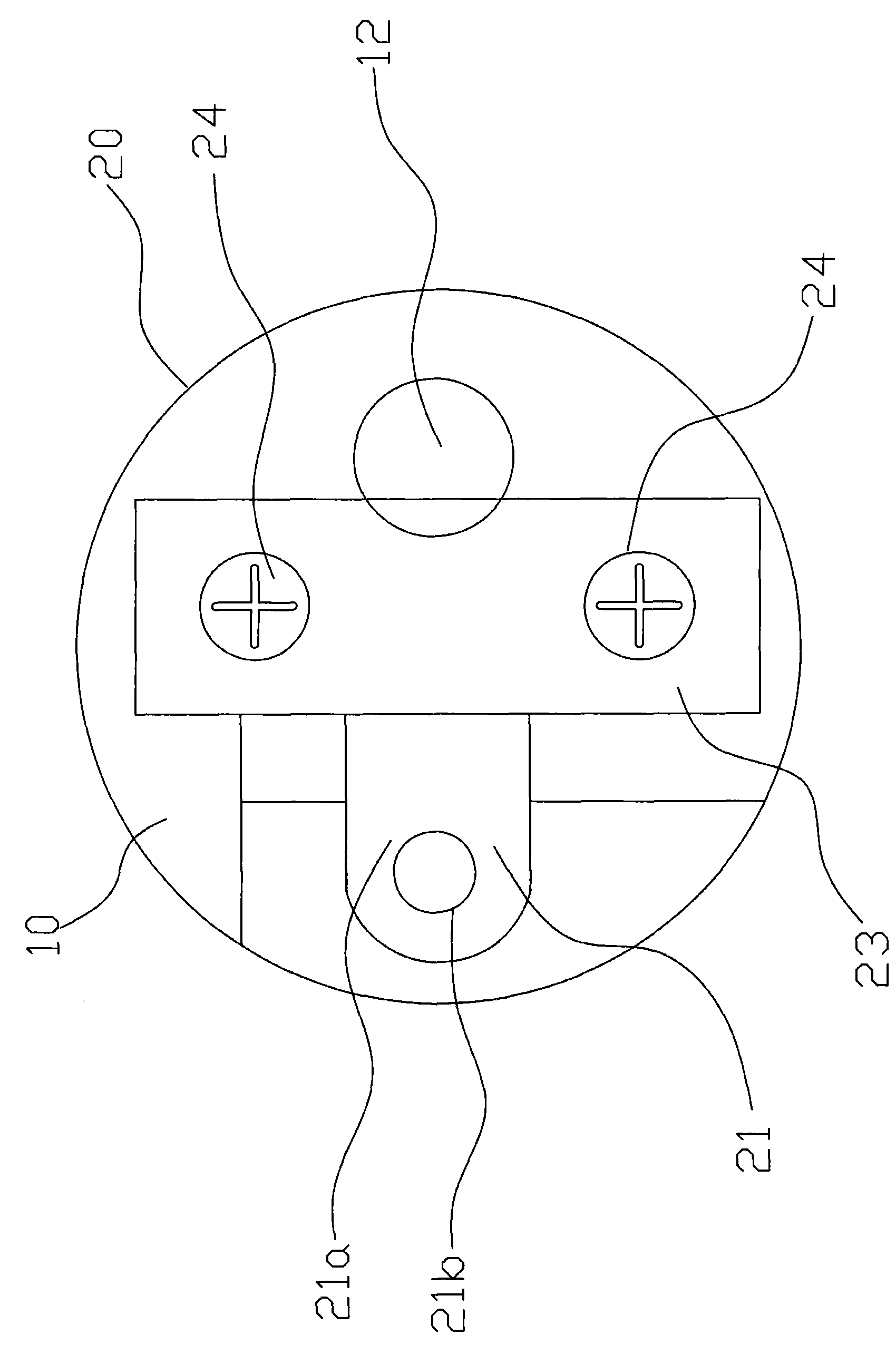

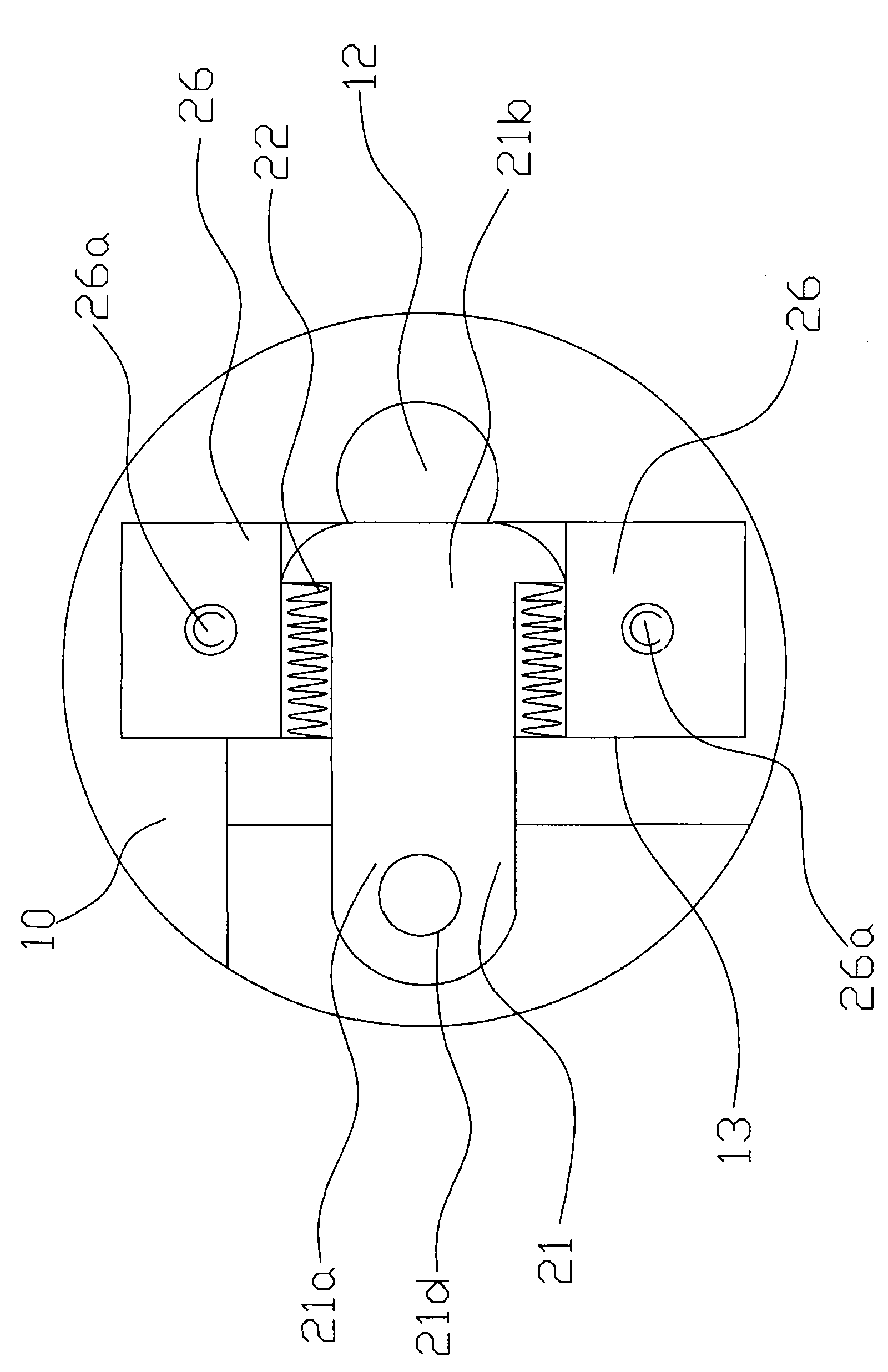

[0017] figure 1 is a plan view showing a jig 1 dedicated to a semiconductor module manufacturing process according to an exemplary embodiment of the present invention. figure 2 is a partial plan view showing the structure of a positioning slider according to an exemplary embodiment of the present invention. image 3 is a partial top view showing the structure of the positioning slider after the cover sheet and screws are removed according to an exemplary embodiment of the present invention.

[0018] like figure 1 As shown, the jig 1 includes a jig body 10 with a certain thickness and several slider assemblies 20 . On the fixture main body 10, there are: several positioning protrusions 11 for matching with positioning holes (not shown) of the workpiece; several thimble holes 12 formed through the fixture main body 10 for making the loading tool (not shown) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com