Automotive electric fitting production splitter

A technology of wire splitter and electrical equipment, applied in the direction of electrical components, etc., can solve the problems of mixed lines, low production efficiency, wrong lines, etc., and achieve the effect of reducing mixed lines, convenient operation, and neat placement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

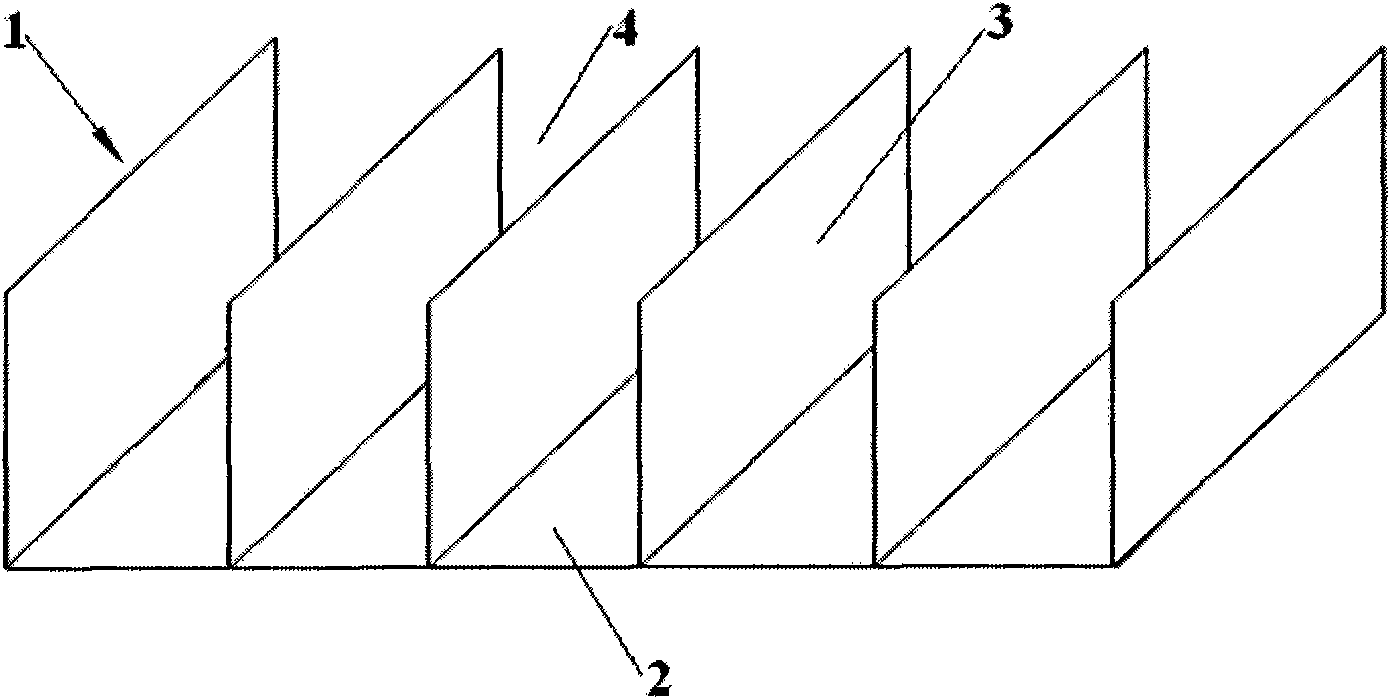

[0024] Considering that the quantity of wires of various specifications (wire diameters) used is unequal, so the spacing between the divider partitions 3 according to the present invention is unequal to accommodate the storage of wires of different wire diameters.

Embodiment 2

[0026] The connection between the splitter partition 3 and the bottom plate 2 of the splitter according to the present invention is a fixed connection. Metal or non-metal plates are used for welding.

Embodiment 3

[0028] Due to the replacement of products, the ratio of the number of wires of various specifications changes. In order to adapt to this change, the connection between the splitter partition plate 3 and the splitter bottom plate 2 of the present invention is a slot-type connection. The width of the line distribution slot 4 can be easily adjusted to adapt to changes in the ratio of the number of wires.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com