Process for preparing alkyl aryl sulphonic acids and alkyl aryl sulphonates

A technology for alkylarylsulfonic acid and alkylaromatic hydrocarbons, which is applied in chemical instruments and methods, preparation of sulfonic acid, preparation of halogenated hydrocarbons, etc., and can solve problems such as unsuitable circulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

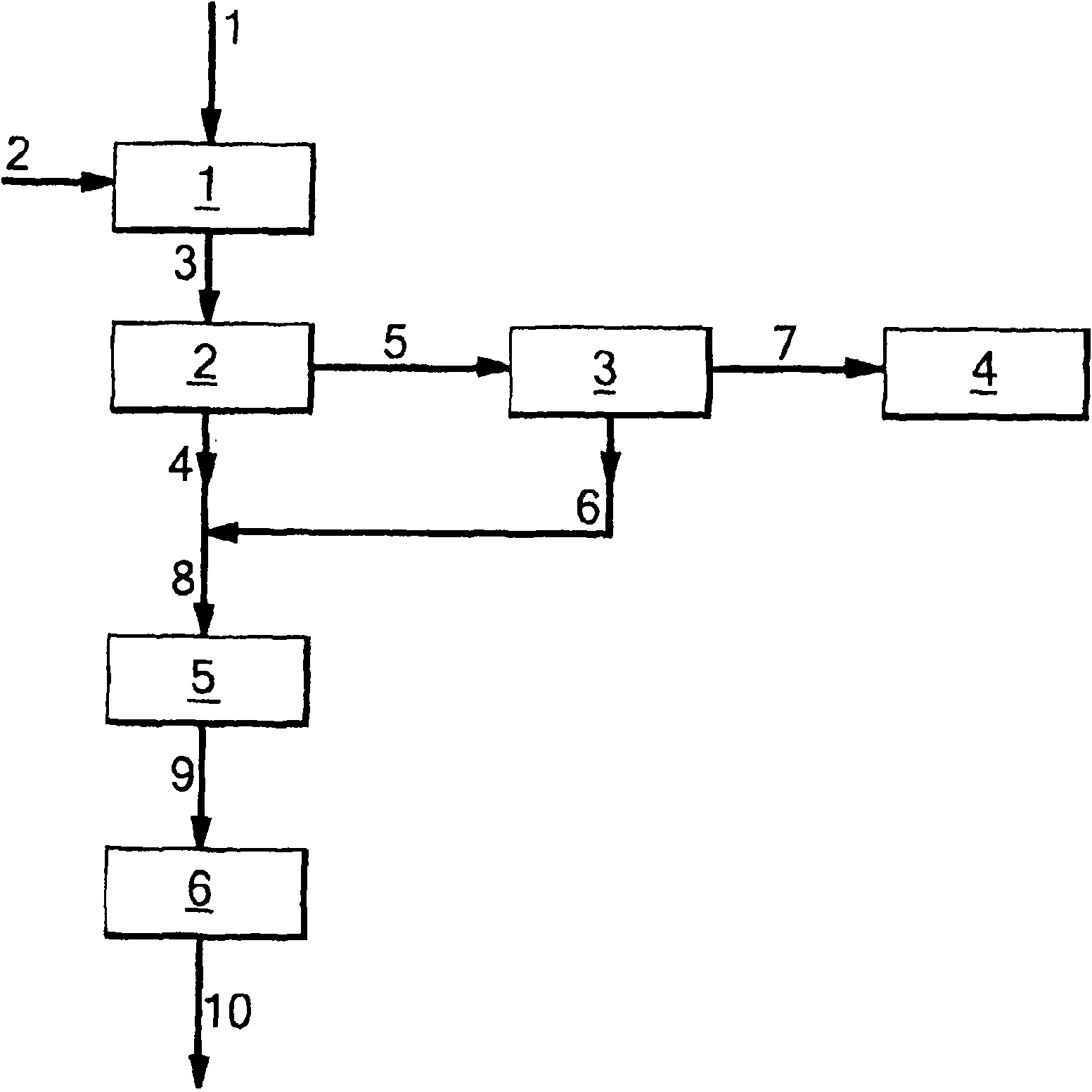

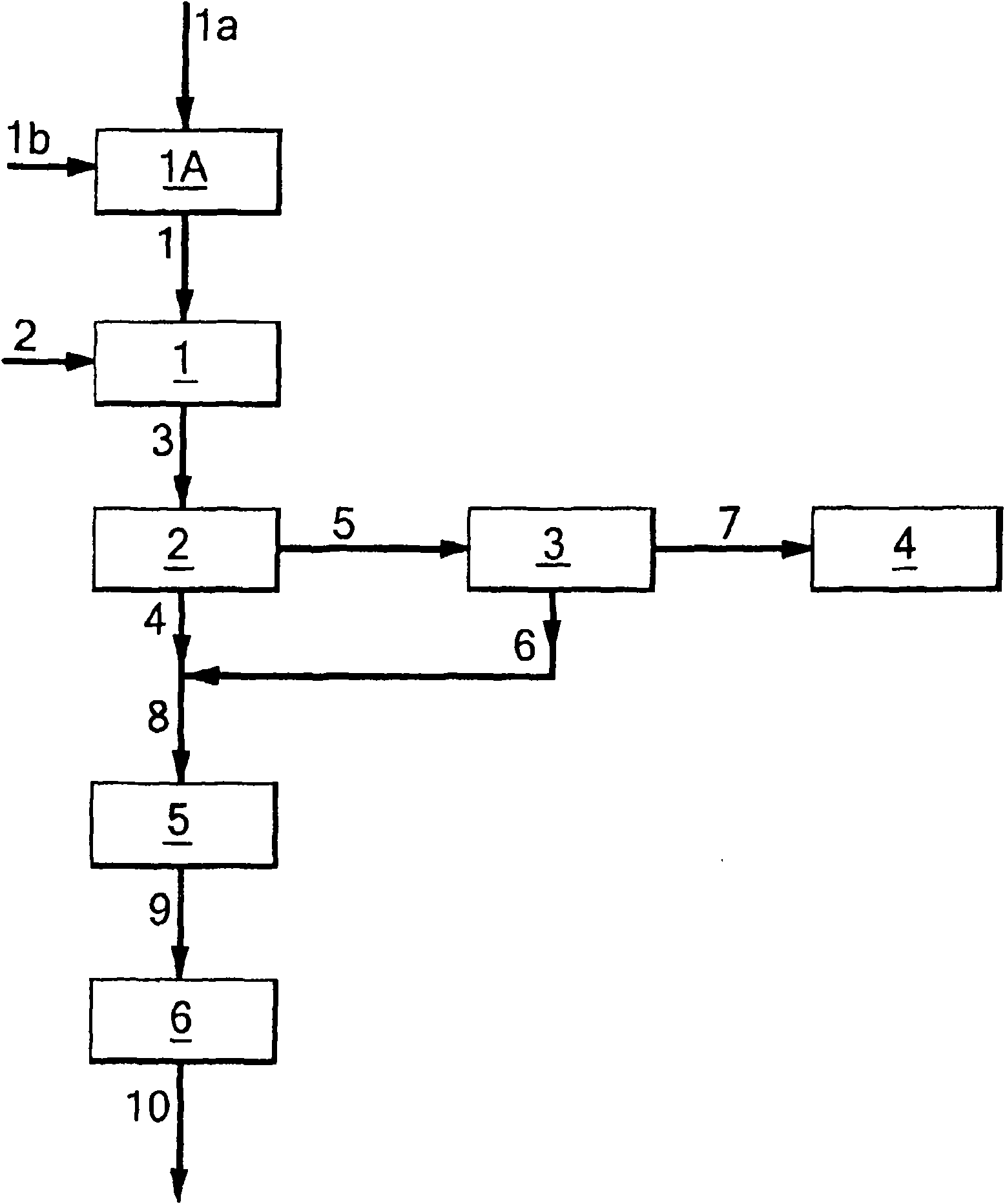

Method used

Image

Examples

Embodiment 1

[0064] Linear alkylbenzenes are produced by dehydrogenation of Fischer-Tropsch derived paraffin feedstock using UOP's PACOL (RTM) process and DEFINE (RTM) process, followed by alkylation using HF as the alkylation catalyst. Preparation of Fischer-Tropsch paraffins in a Fischer-Tropsch reaction using a cobalt-titania Fischer-Tropsch catalyst. The desired carbon fraction is obtained by a combination of distillation and hydrogenation. The resulting Fischer-Tropsch paraffin has the following composition:

[0065] Paraffin carbon number

weight%

C9 and lighter

0.0

C10

10.3

C11

31.0

C12

29.9

C13

28.2

C14 and heavier

0.6

[0066] Linear alkylbenzenes (LAB) are then subjected to sulfonation by reaction with sulfur trioxide. Use elemental sulfur as the base material, which is melted and burned to SO 2 and subsequent conversion to SO 3 to produce sulfur trioxide. 6mol%SO at a f...

Embodiment 2

[0081] Embodiment 2 (comparison)

[0082] Example 1 was repeated except that the acidic liquor drained from the electrostatic precipitator (ESP) was not recycled. Samples of the final linear alkylbenzene sulfonic acid product were measured for absorbance, immediate acidity, UOM (unreacted organic matter), water content, and sulfuric acid content using the test methods described above. The results are shown in Table 1 below.

Embodiment 3

[0083] Embodiment 3 (comparison)

[0084] Example 1 was repeated except that linear alkylbenzenes were produced by dehydrogenating a C9-C14 kerosene derived paraffin feedstock. The alkyl groups of the resulting alkylarylsulfonic acids have the following carbon number distribution:

[0085] Alkyl carbon number

[0086] Samples of the final linear alkylbenzene sulfonic acid product were measured for absorbance, immediate acidity, UOM (unreacted organic matter), water content, and sulfuric acid content using the test methods described above. The results are shown in Table 1 below.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com