Inorganic light weight thermal insulation wall tile forming machine and forming method

A technology for wall tiles and forming machines, applied in the direction of forming pressure head, supply device, unloading device, etc., which can solve the problems of small force-bearing area of the pressing surface, high operation intensity, long time consumption, etc., and achieve production efficiency Low, high degree of automation, the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

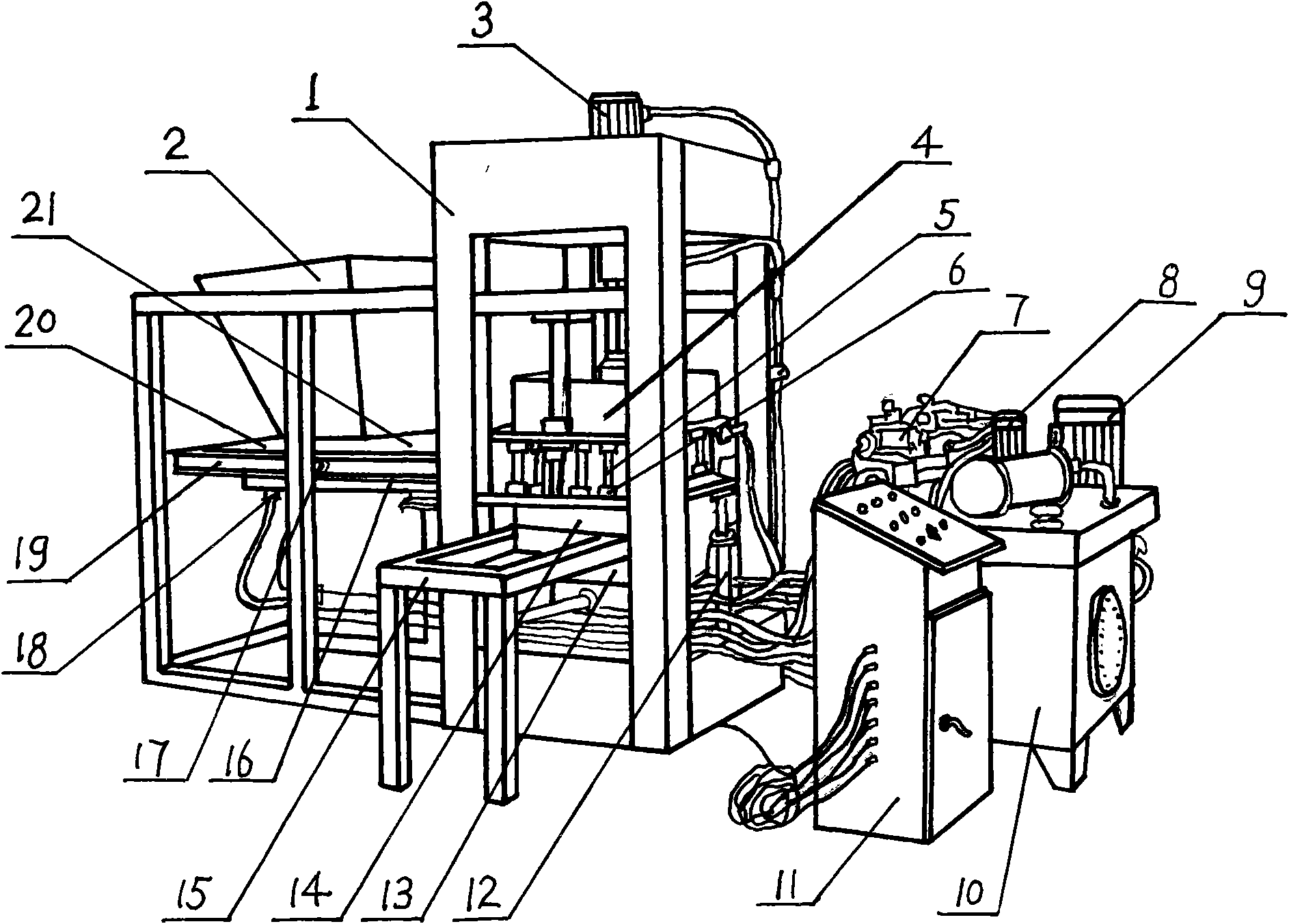

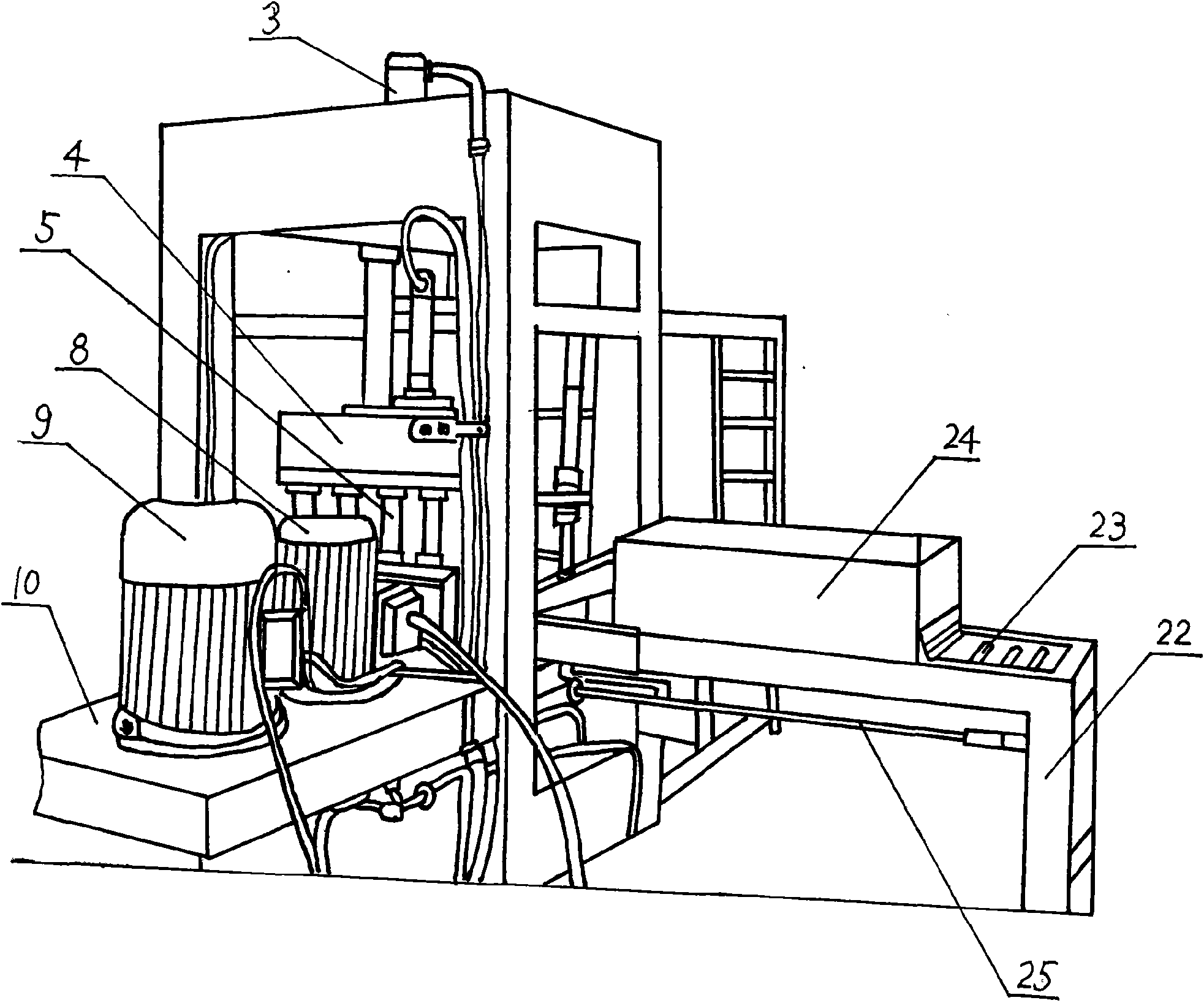

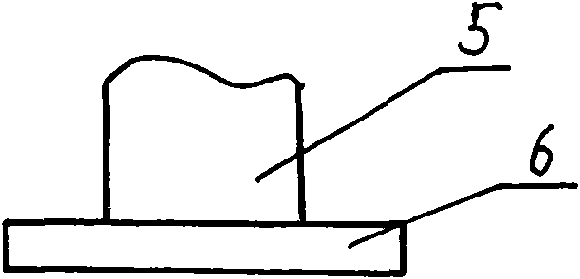

[0024] see figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , the inorganic lightweight thermal insulation wall brick forming machine of the present invention is composed of a frame 1, a molding device, a feeding device, a blanking device, a hydraulic station 10 and an electric control cabinet 11, wherein the frame 1 is a frame structure, and the molding device Installed in the frame 1, the device includes an upper die base 4, an upper die 5, a lower die base 13, a lower die 14, a main hydraulic cylinder 3 and a lower die lifting cylinder 12. The main hydraulic cylinder 3 is installed on the frame 1. The top of the lower plunger is fixedly connected to the upper die base 4 and the upper die 5 in turn. 16 to 80 die heads 6 integrated with the upper die are arranged and arranged on the punching surface of the upper die 5, and 16 to 80 wall tiles can be formed by punching at one time. The punching surface of the die head 6 is provided with evenly distributed protrusio...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap