Soft material producing method with 2D and 3D effects

A technology of soft materials and manufacturing methods, which is applied in the process, chemical instruments and methods, decorative arts and other directions for producing decorative surface effects, can solve the problems of easy distortion and blurring of printed graphics, and achieves easy distortion and application range. wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

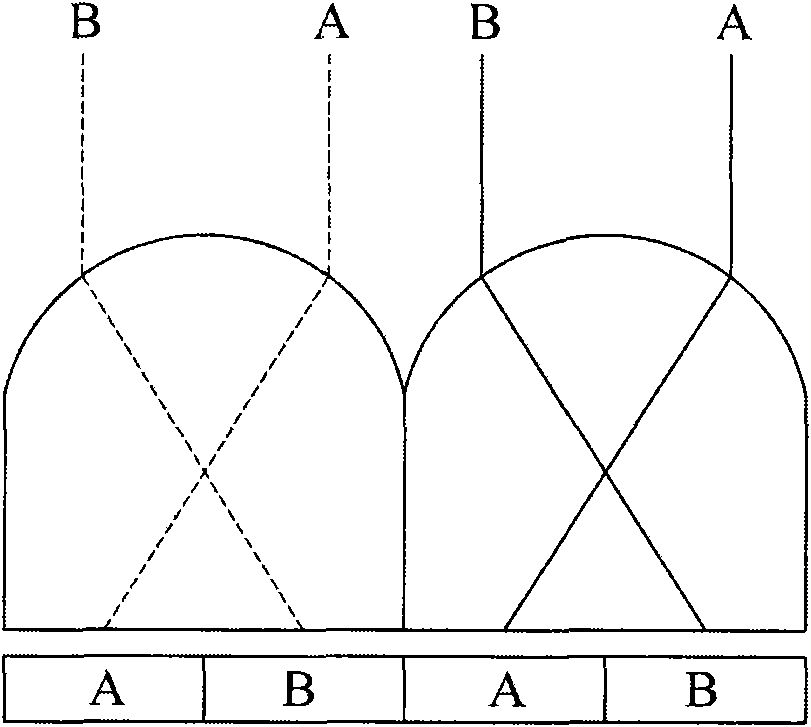

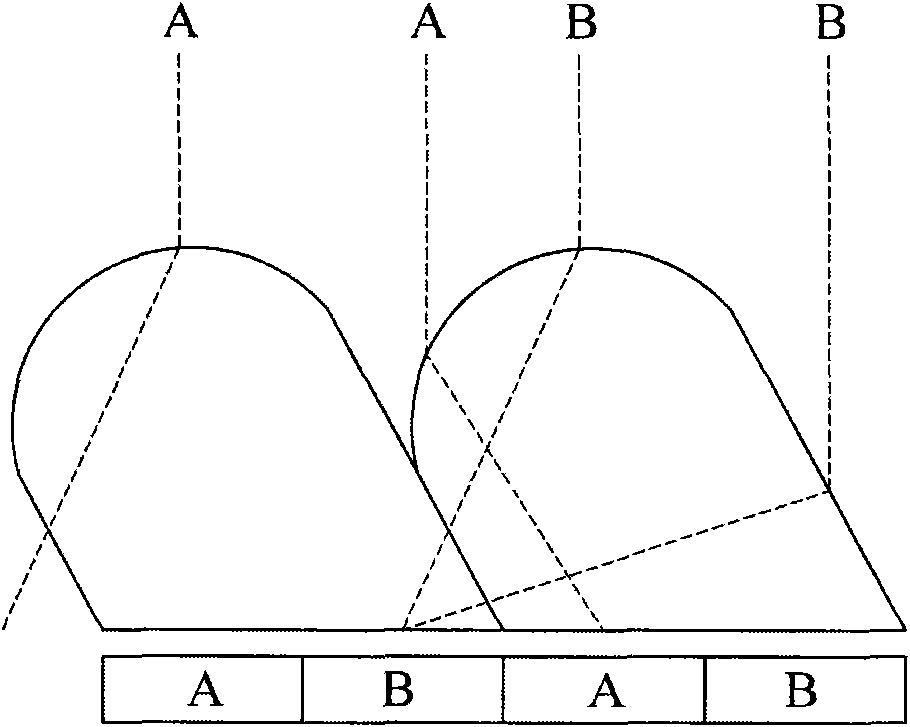

[0032] The method for manufacturing soft materials with 2D and 3D effects according to the present invention will be further described below in conjunction with the accompanying drawings.

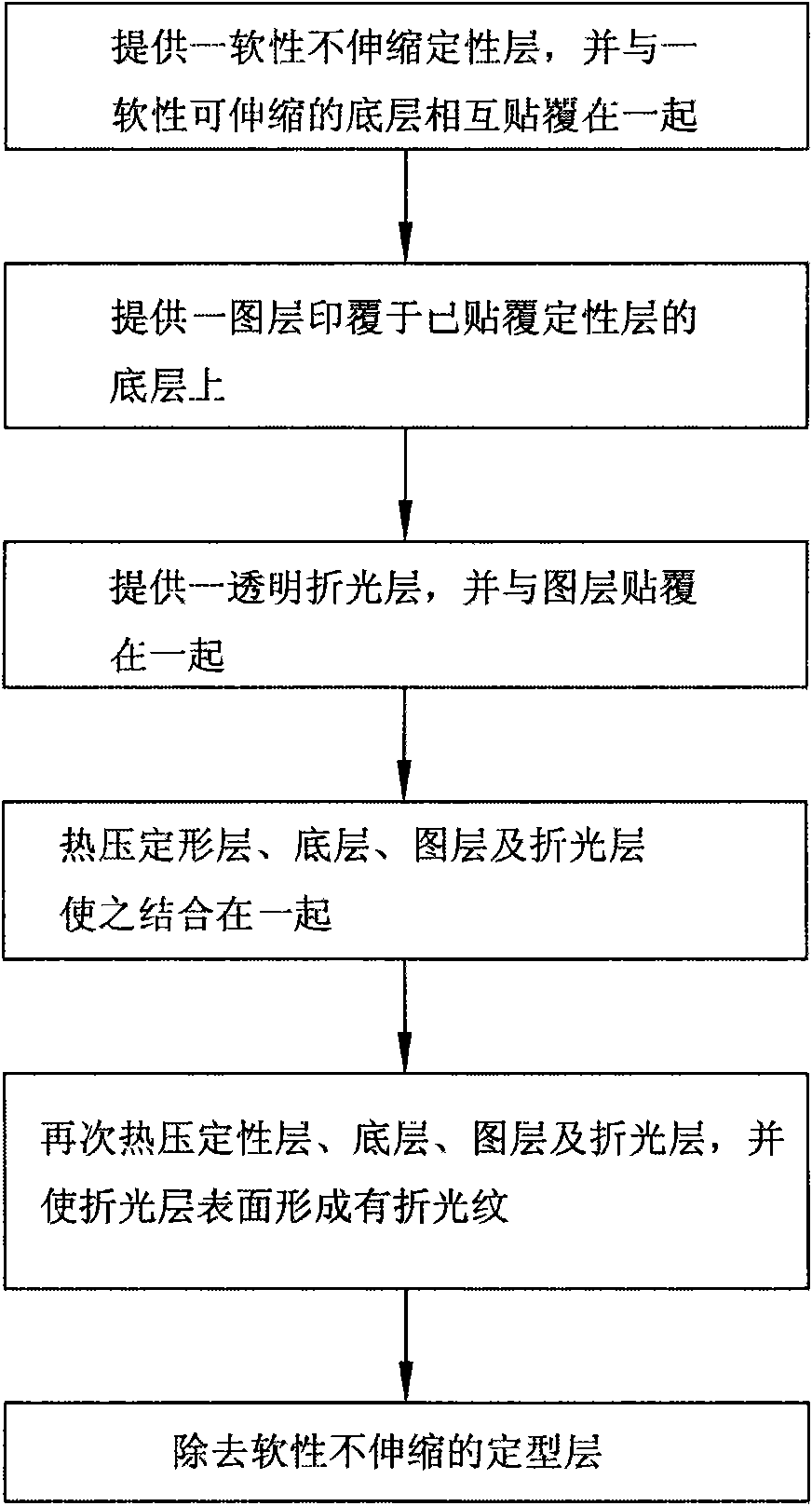

[0033] like figure 2 as shown, figure 2 It is a flow chart of the soft material manufacturing method with 2D and 3D effects of the present invention. The method comprises the steps of:

[0034] a. Provide a soft non-stretch shaping layer, and stick together with a soft stretchable bottom layer;

[0035] b. Provide a layer to be printed on the bottom layer that has been pasted with the shaping layer;

[0036] c. Provide a transparent refraction layer and paste it together with the layer;

[0037] d. The heat-pressed setting layer, the bottom layer, the layer and the refractive layer are combined together;

[0038] e. heat-press the shaping layer, the bottom layer, the layer and the refraction layer again, and form refraction patterns on the surface of the refraction layer;

[0039] f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com