Device for making a combed fiber web

A technology of fiber webs, equipment, applied in the direction of fiber processing, combing machines, textiles and paper making, to achieve the effect of simple manufacturing tolerances

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

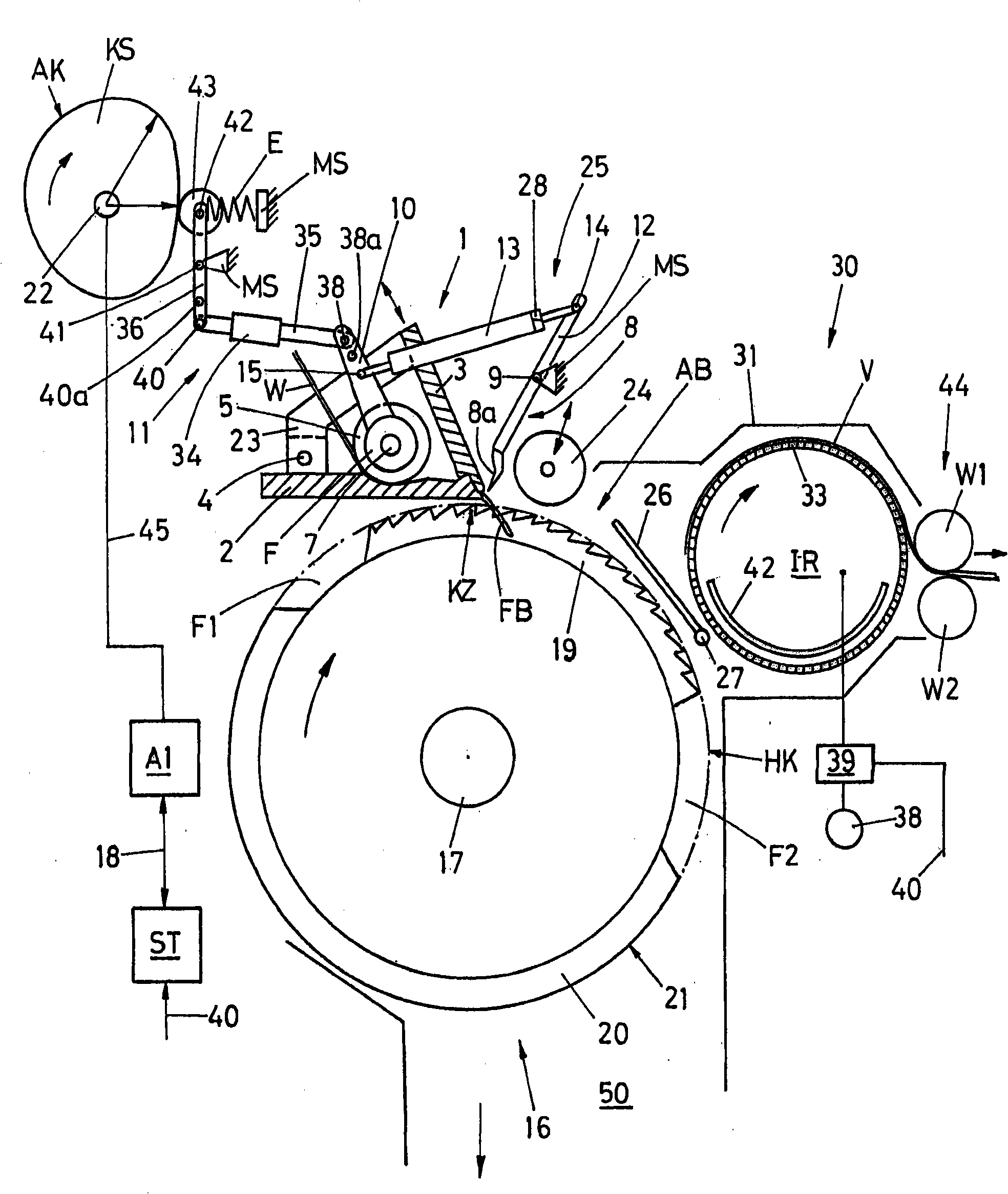

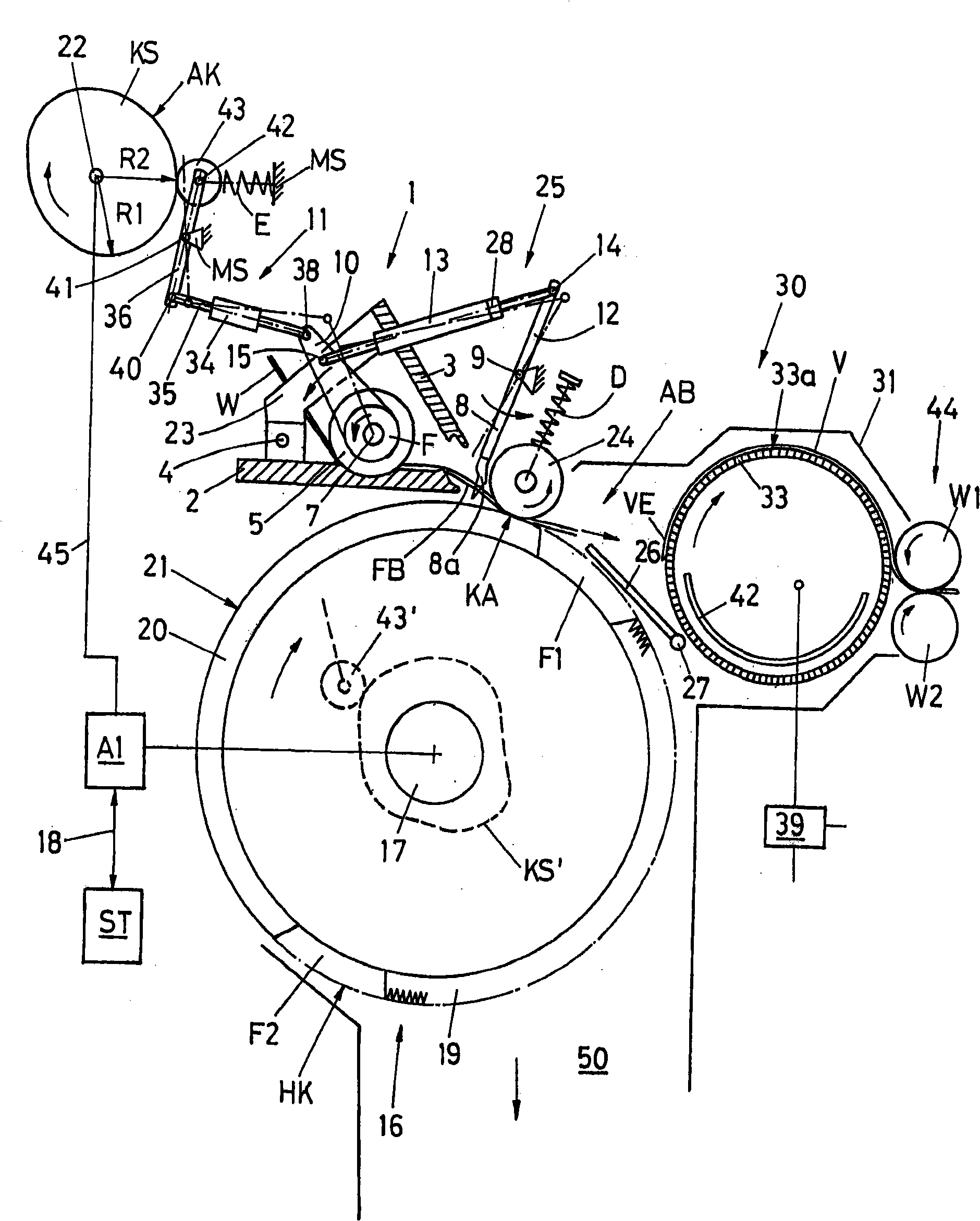

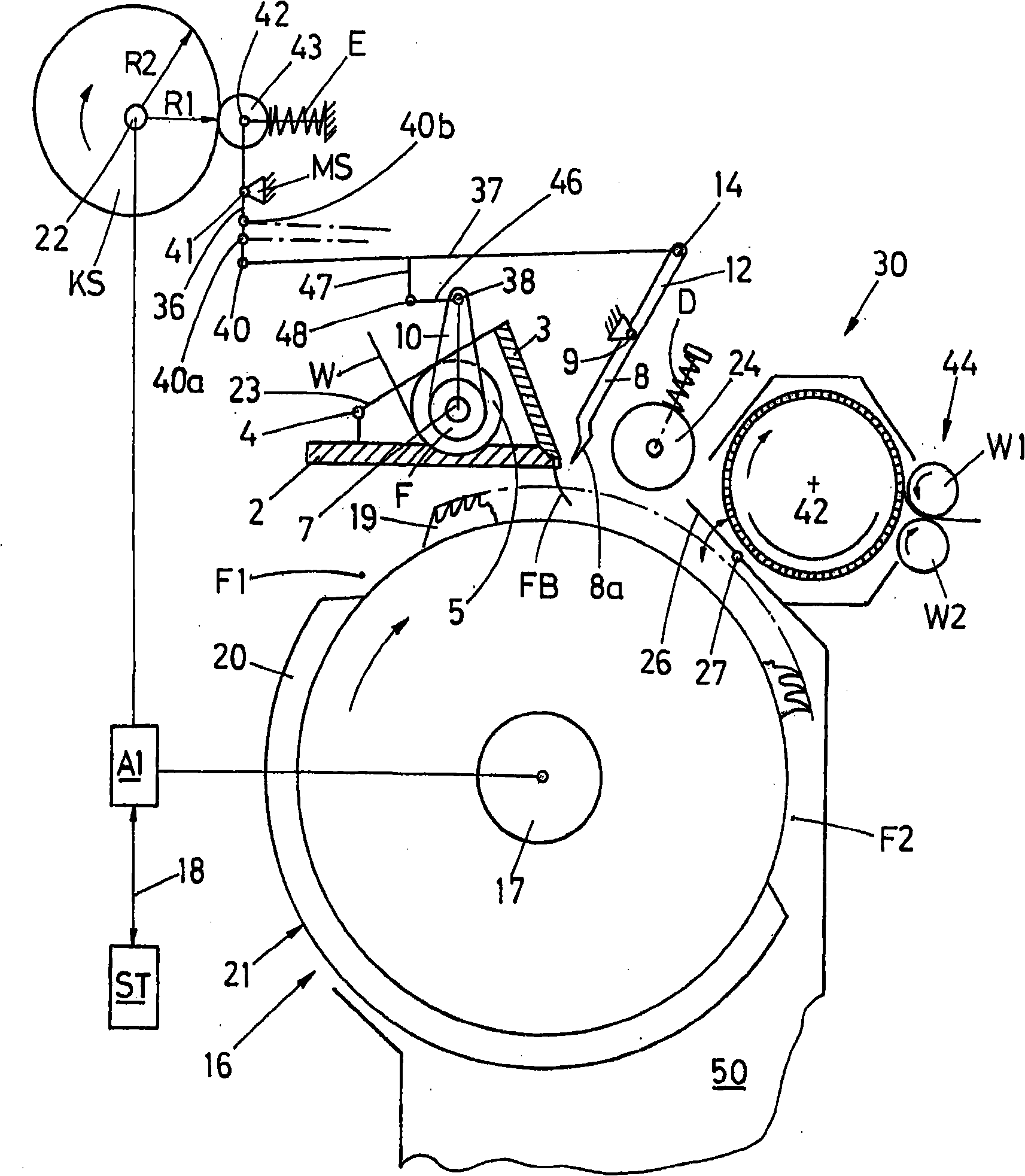

[0030] figure 1 Shown is a jaw assembly 1 of a combing machine (referred to simply as nipper) with a substantially stationary lower nipper 2 and with nippers 3 mounted movably relative to the lower nipper. In this example, the nipper blade 3 is fixed on an arm 23 pivotably mounted about an axis 4, which arm is fixed in the frame or on the lower nipper plate 2, as shown.

[0031] In the illustration shown, the tongs are closed, the nipper blade 3 and the lower nipper 2 form a nip point KZ for clamping a sliver W.

[0032] The sliver W can be formed, for example, from a sliver sheet unwound from a sliver roll, not shown in detail. It is also possible for the sliver W to consist of one or more fiber slivers (sliver) supplied next to each other. In the case of using fiber slivers, the fiber slivers are fed from cans installed at the combing machine. This example shows only one grooming head.

[0033] Generally, however, a plurality of such carding heads are arranged side by si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com