Replaceable unit curtain wall panel system

A unit curtain wall, replacement technology, applied in the direction of walls, building components, buildings, etc., can solve the problems of easily damaged profiles, easy loosening, noise, etc., and achieve the effect of good limit effect and long service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

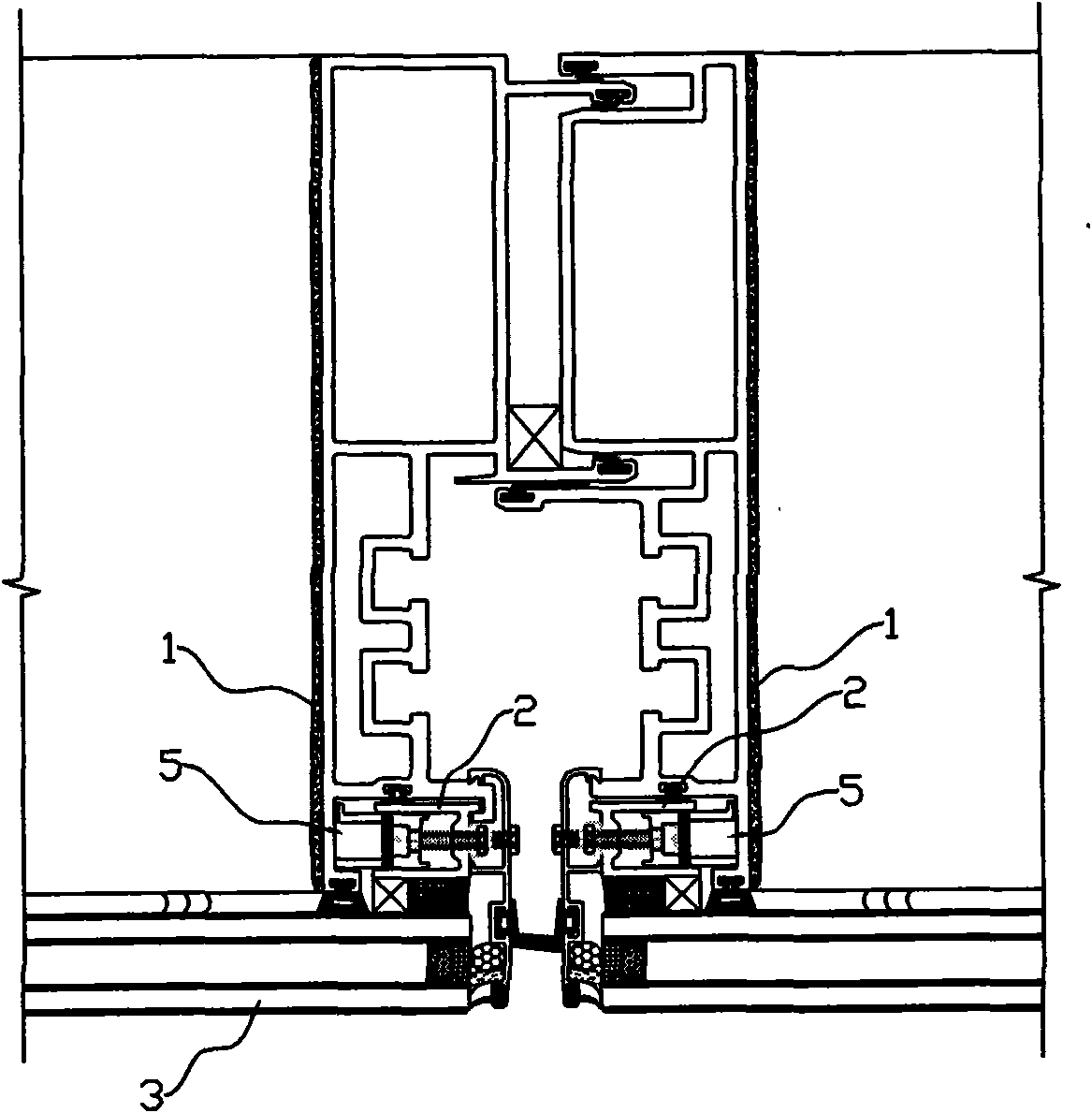

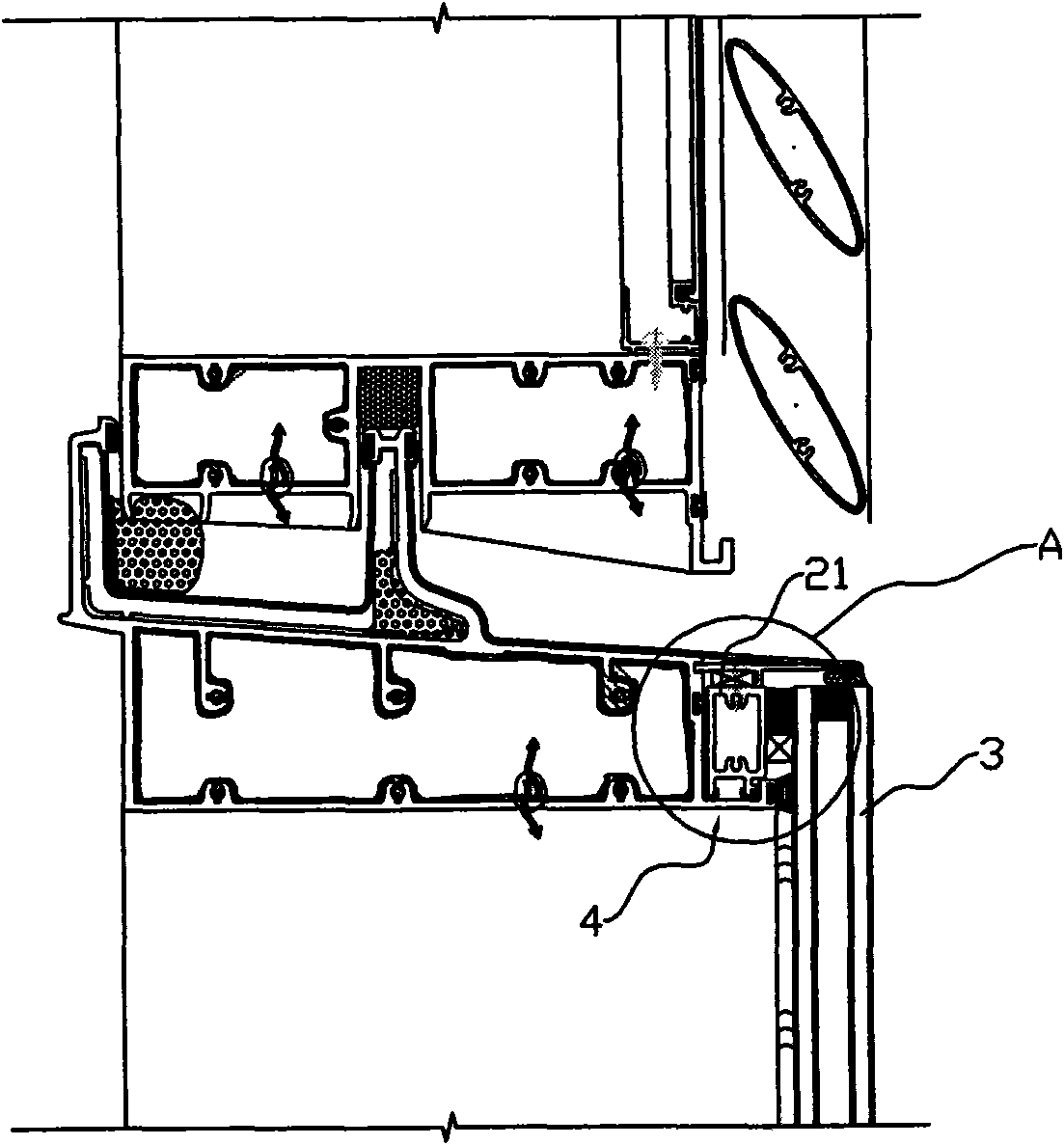

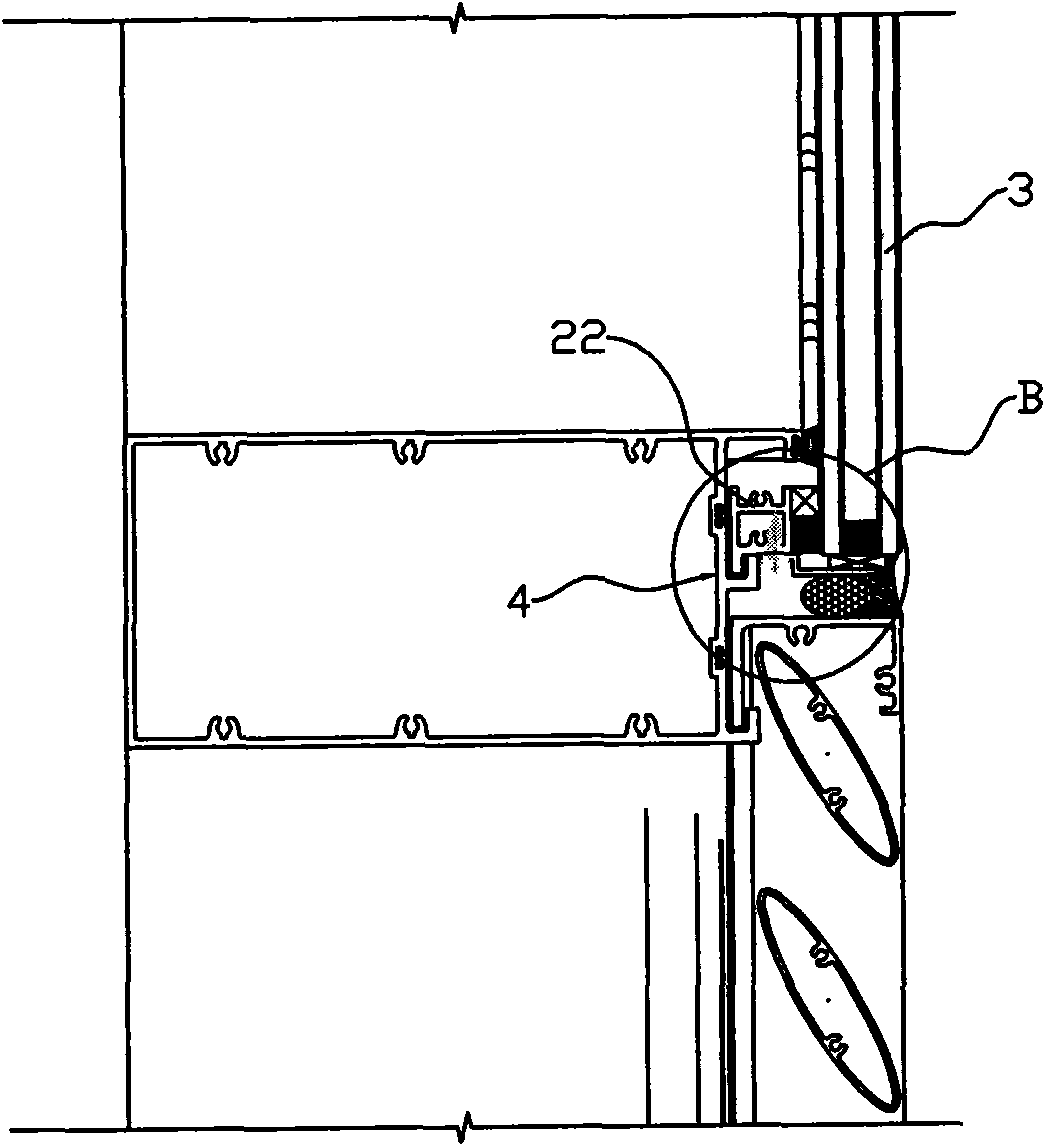

[0017] refer to Figure 1 to Figure 4 , the replaceable unit curtain wall panel system of the present invention comprises a unit curtain wall base 1, an aluminum alloy sub-frame 2 and a curtain wall glass 3 installed on the aluminum alloy sub-frame 2, and the aluminum alloy sub-frame 2 is made of upper and lower transverse materials Belts 21, 22 and left and right vertical material belts 23, 24 are composed of the upper and lower horizontal material belts 21, 22 and the unit curtain wall substrate 1 respectively provided with a hooking mechanism 4, the left and right vertical Telescopic positioning mechanisms 5 are respectively arranged on the material belts 23 and 24 . Because this unit curtain wall system adopts the above-mentioned structure, the aluminum alloy sub-frame 2 equipped with curtain wall glass can be hung on the beam of the unit curtain wall base through the hooking mechanism 4 first, and then the aluminum alloy sub-frame can be fixed by the telescopic positionin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com