Heat pump water heater

A technology of heat pump water heaters and outdoor heat exchangers, which is applied in the field of heat pump water heaters and air source heat pump water heaters, and can solve problems such as high cost, low energy efficiency ratio, and failure to work normally

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

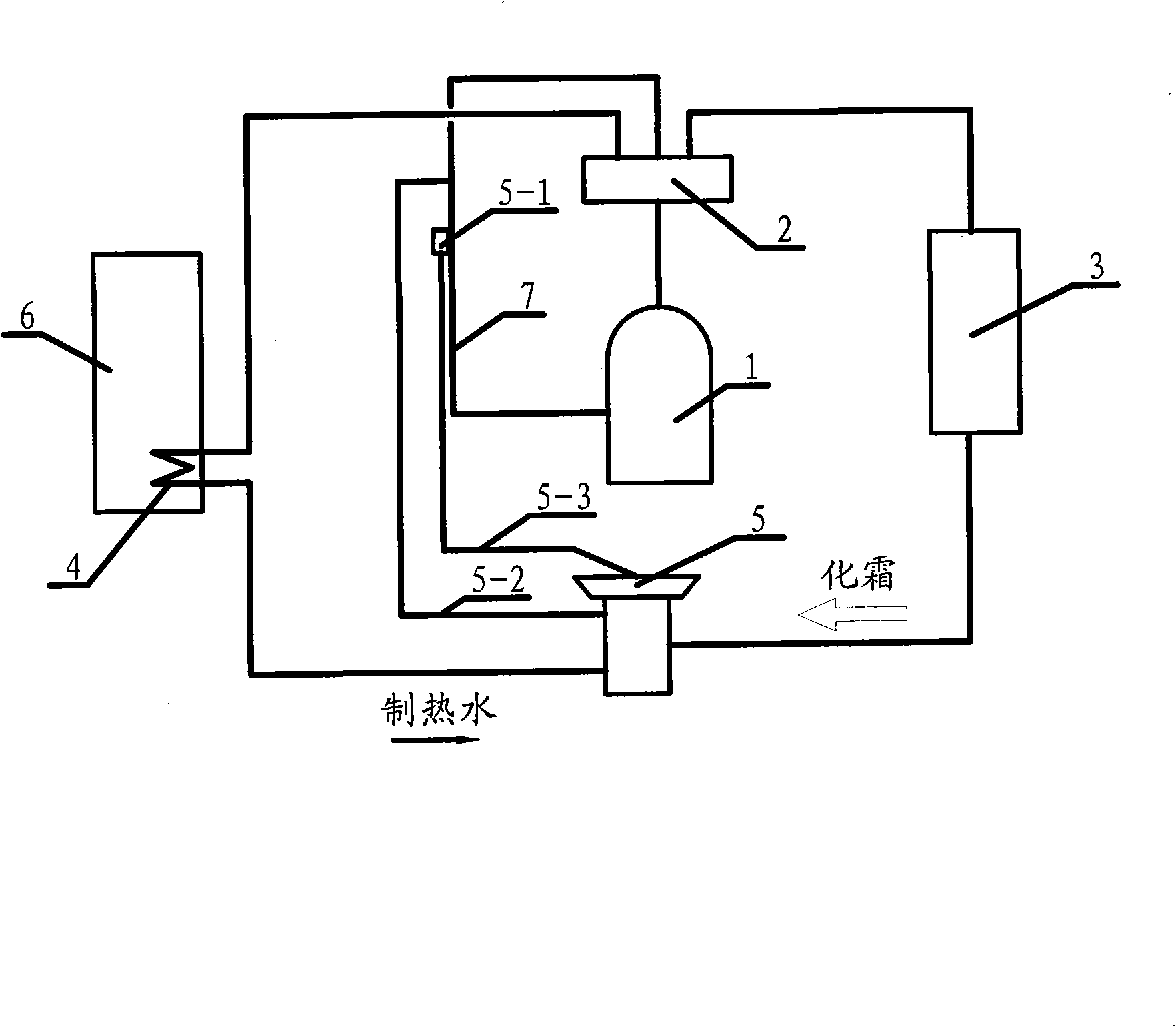

[0013] this invention figure 1 In the shown heat pump water heater system, the external balance and external temperature-sensitive bidirectional thermal expansion valve 5 has two liquid connecting pipes at its lower end respectively connected with the indoor heat exchanger 4 and the outdoor heat exchanger 3, and the pressure transfer pipe 5- 2 is connected with the air return pipe 7 to feel the return air pressure flowing through the air return pipe 7, and the temperature sensing tube 5-1 senses the return air temperature flowing through the air return pipe 7 through the connection capillary 5-3.

[0014] The working principle of the heat pump water heater is as follows: the low-pressure gaseous refrigerant is compressed by the compressor 1 into a high-temperature and high-pressure gaseous refrigerant, and the high-temperature and high-pressure gaseous refrigerant enters the indoor heat exchanger 4 through the four-way electromagnetic reversing valve 2 to exchange heat with the...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap