Method and system for realizing real-time scheduling of job shop

A job shop, real-time scheduling technology, applied in the field of automation, can solve the problems of production process delay, slow response of the scheduling system, and time-consuming, so as to improve efficiency, meet the requirements of real-time scheduling, and speed up the response speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

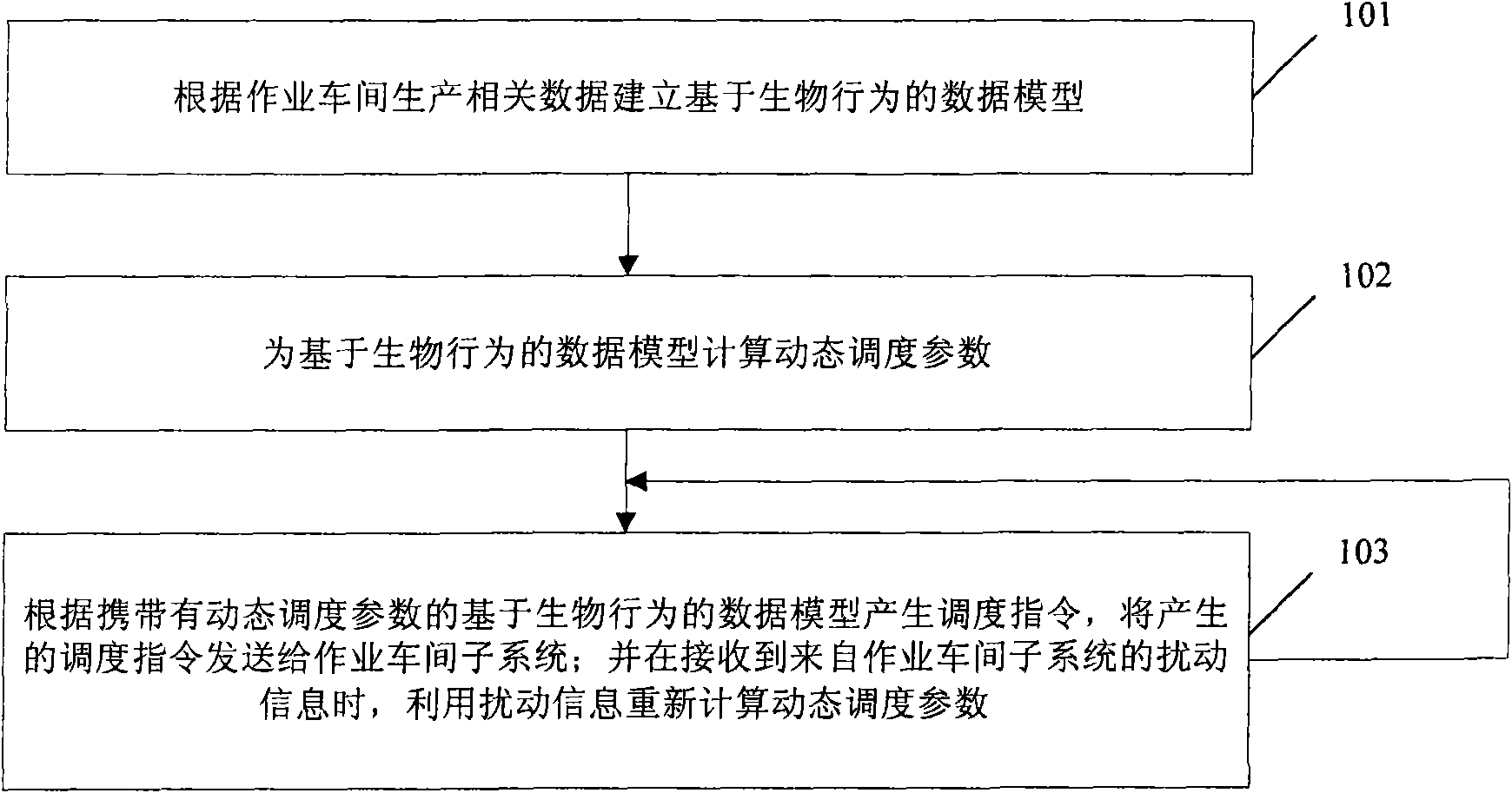

[0060] The basic idea of the present invention is to use the biological behavior-based data model to model the production-related data of the job shop, and calculate the dynamic scheduling parameters; after that, the biological behavior-based data model that carries the dynamic scheduling parameters can be directly used in turn. Generate scheduling instructions, and recalculate dynamic scheduling parameters when disturbance information is received, so as to speed up the response to disturbance information and achieve the purpose of real-time scheduling.

[0061] figure 1 It is a flowchart of Embodiment 1 of a method for realizing real-time scheduling of a job shop in an embodiment of the present invention. Such as figure 1 As shown, this embodiment includes:

[0062] Step 101: Establish the production-related data of the job shop as a data model based on biological behavior.

[0063] In this step, the biological behavior-based data model is mainly a data model established by ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com