Glue-sealed type electric connector

An electrical connector, sealing technology, applied in the field of sealed electrical connectors, can solve the problems of lengthening size, sealing function failure, high price, etc., and achieve the effect of reducing size, good sealing performance and simple structure

Inactive Publication Date: 2010-11-10

GUIZHOU SPACE APPLIANCE CO LTD

View PDF1 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

General rubber-sealed electrical connectors (hereinafter referred to as products) are generally provided with multiple annular ribs and grooves in the glue-filling cavity at the end of the product, and are sealed and prevented by potting multi-layer sealants (commonly known as insulators). Base) out of the shell, such as in 200720123196.9 "the socket end adopts a three-layer sealant structure, which are primer, sealant, and sealant structure", but this structure lengthens the dimension in the docking direction. In addition, Due to the inconsistent thermal expansion coefficients of different sealants, especially the hardening of the sealant at low temperature often leads to the failure of the sealing function of the product, and the amount of sealant used in potting is large and expensive

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

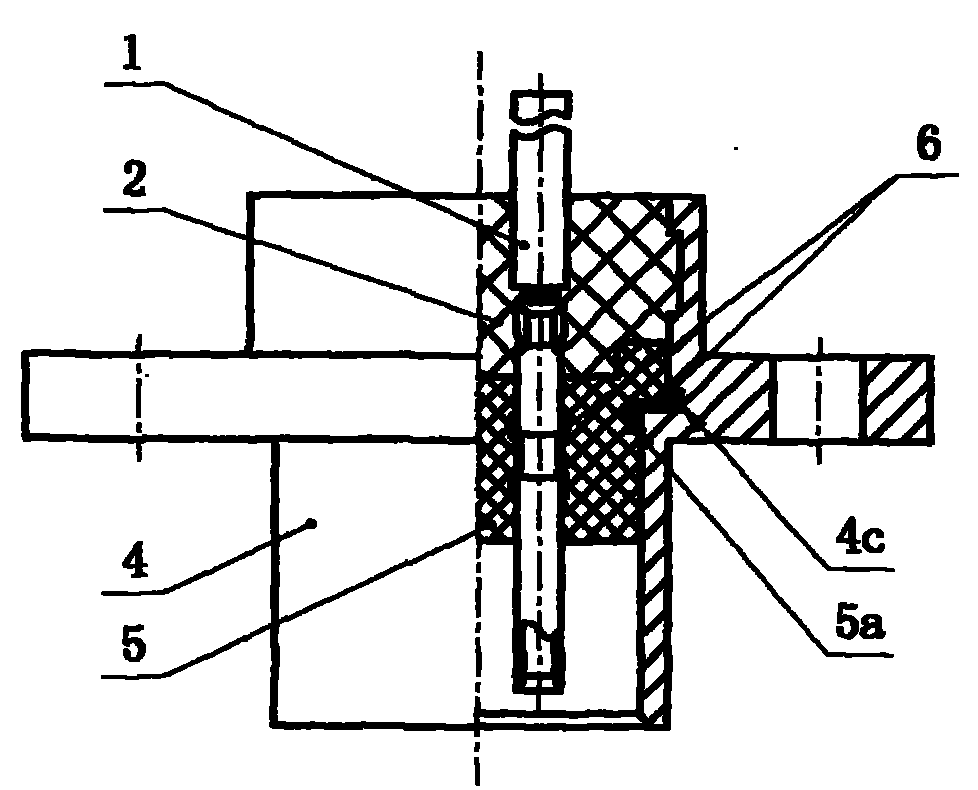

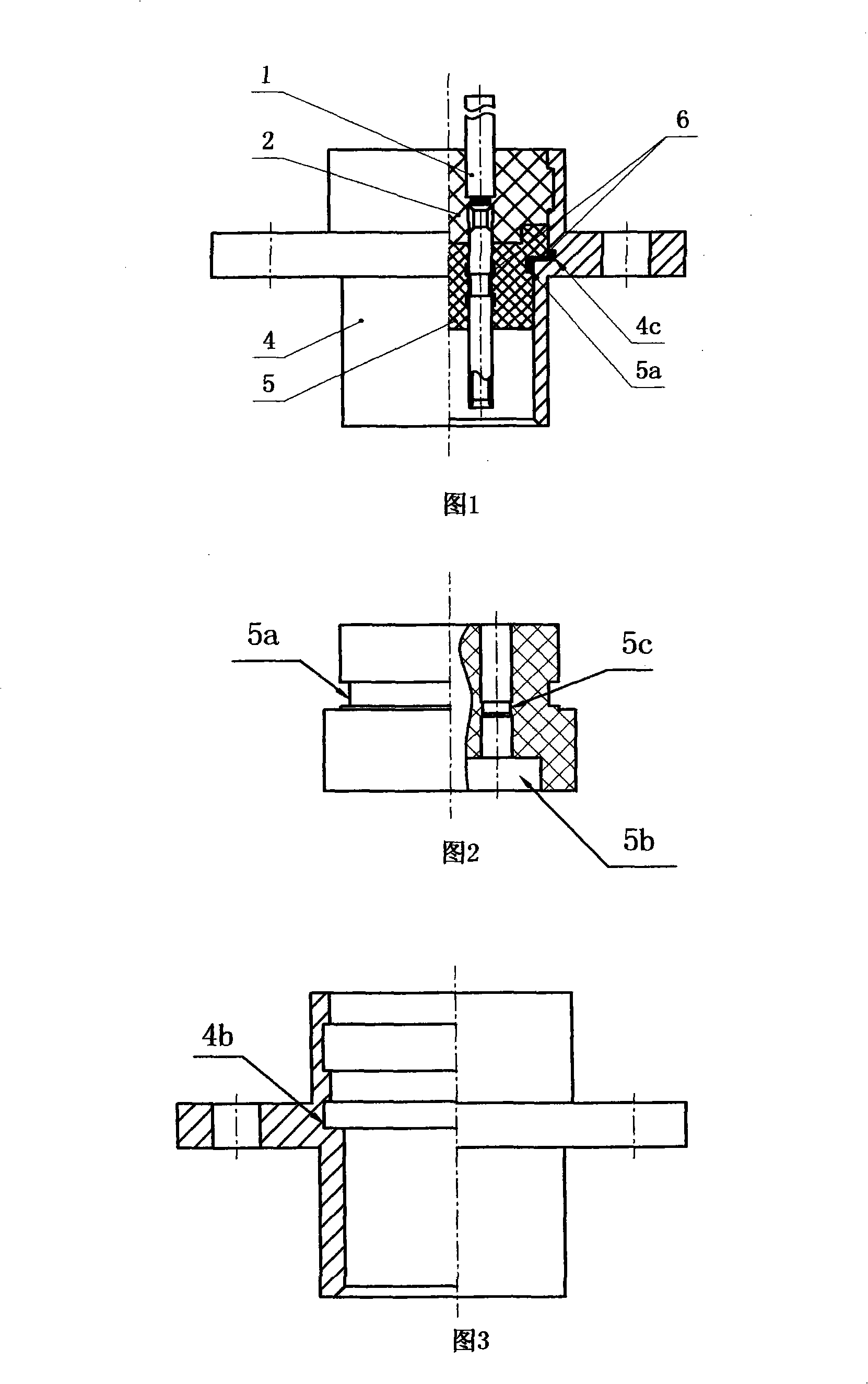

The invention discloses a glue-sealed type electric connector which consists of a contact element, an outer shell and a pedestal; the contact element and the pedestal are arranged inside the outer shell; the step of the outer edge of the pedestal is provided with an annular groove; the corresponding location of the step of the inner bore of the outer shell is provided with an annular seal groove;after the pedestal is arranged in the outer shell, a communicated cavity formed by the annular groove of the pedestal, the step of the outer shell, the annular groove of the inner bore of the outer shell is injected with seal gum; the seal gum is also injected between the contact element and the pedestal, and is further injected among the internal cavity of the outer shell at the tail end of the connector, the pedestal and the contact element. The glue-sealed type electric connector has the advantages of simple structure and good sealing property, thus avoiding the problems caused by the inconsistent heat expansion coefficients of various seal gum and effectively reducing the dimension of the butt-joint direction of the connector.

Description

A glue-sealed electrical connector technical field The invention relates to a non-glass-sealed glue-sealed electrical connector, which belongs to the technical field of sealed electrical connectors. Background technique General rubber-sealed electrical connectors (hereinafter referred to as products) are generally provided with multiple annular ribs and grooves in the glue-filling cavity at the end of the product, and are sealed and prevented by potting multi-layer sealants (commonly known as insulators). Base) out of the shell, such as in 200720123196.9 "the socket end adopts a three-layer sealant structure, which are primer, sealant, and sealant structure", but this structure lengthens the dimension in the docking direction. In addition, Due to the inconsistent thermal expansion coefficients of different sealants, especially the hardening of the sealant at low temperature often leads to the failure of the sealing function of the product. Moreover, the amount of sealant u...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): H01R13/52

Inventor 徐宗贵

Owner GUIZHOU SPACE APPLIANCE CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com