Glue-sealed type electric connector

An electrical connector and sealing technology, which is applied in the field of sealed electrical connectors, can solve the problems of sealing function failure, lengthened size, and high price, and achieve the effects of good sealing performance, reduced size, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

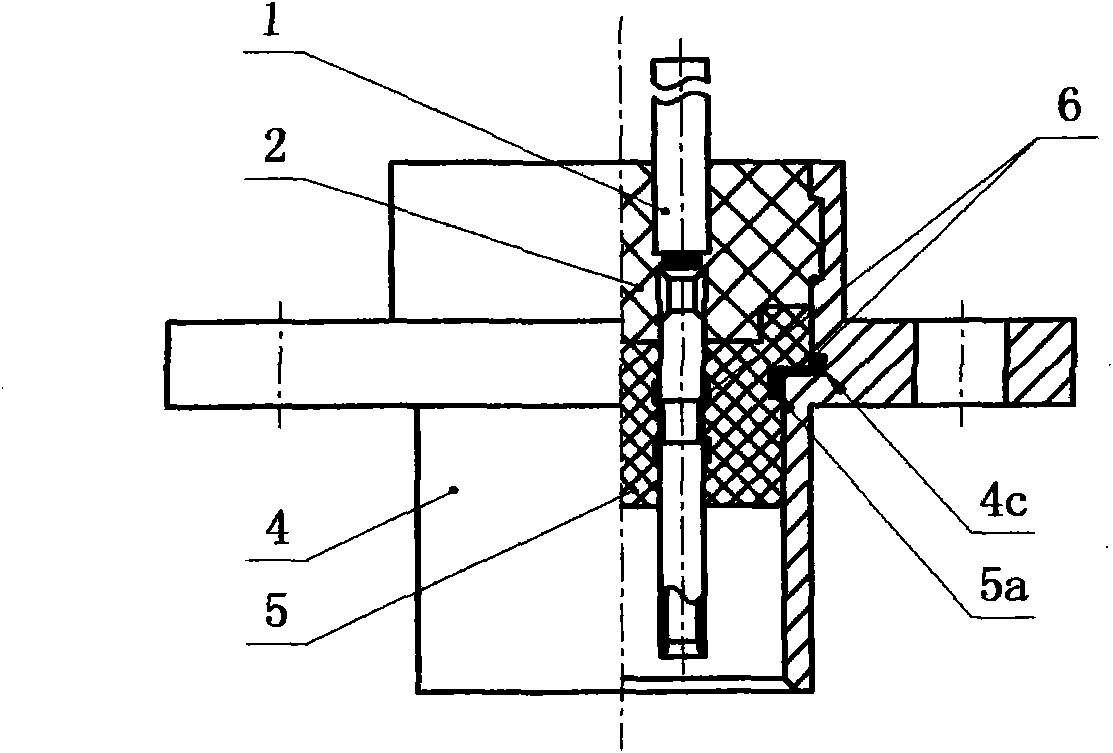

[0014] The present invention is described in detail below in conjunction with accompanying drawing example:

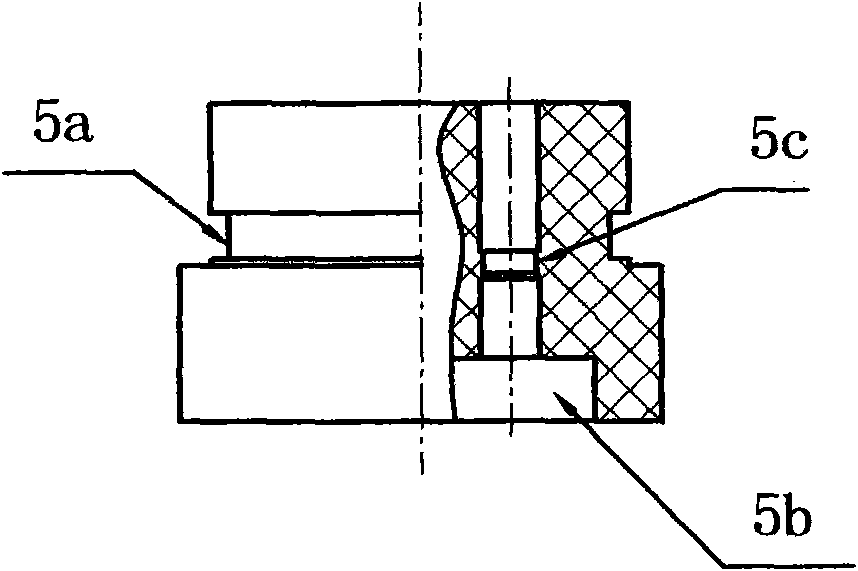

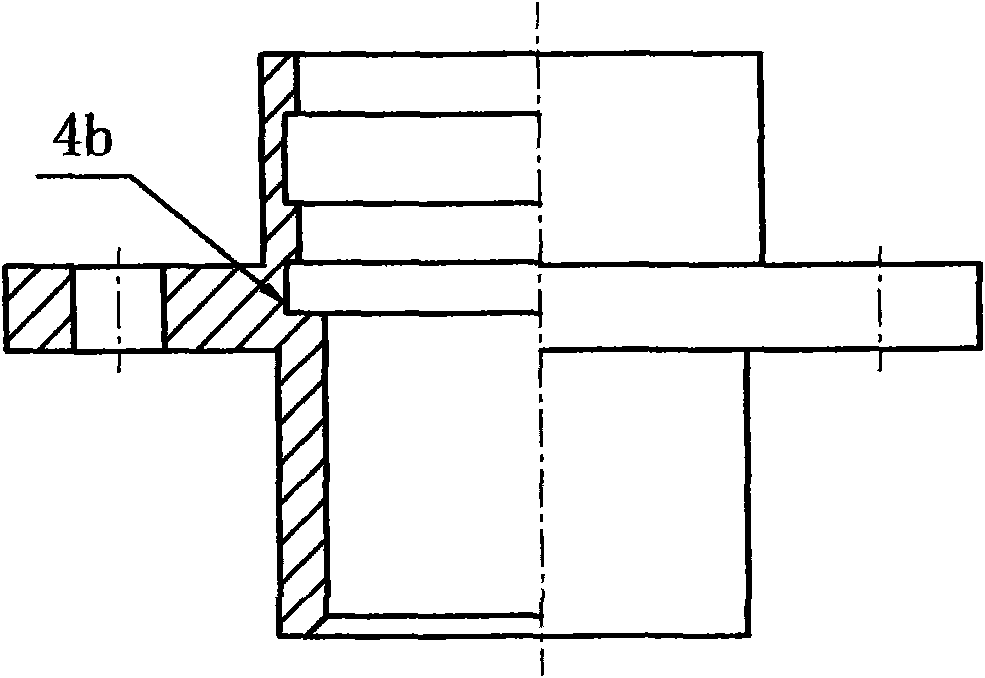

[0015] Such as figure 1 As shown, the rubber-sealed electrical connector of the present invention is composed of a contact piece 1, a housing 4, and a base 5. The contact piece 1 and the base 5 are installed in the housing 4, and the outer edge of the base 5 is provided with a step There is an annular groove 5a, and there is an annular groove 4c corresponding to the step in the inner hole of the shell. When installing the base, first apply the sealant 6 (silicone rubber) to the annular groove 5a of the base, and then put it into the shell. Also when installing the contact piece 1, the sealant is applied first and then put into the base, so that the connected cavity formed by the annular groove 5a of the base, the shell step, and the annular groove 4c of the inner hole of the shell is sealed by the sealant 6, and the tail end shell 4 The sealing structure glue 2 is pou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com