Hydraulic pump

A hydraulic pump and hydraulic system technology, applied in the field of hydraulic pumps, can solve problems such as inability to ensure performance and increase the overall cost of finished pumps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

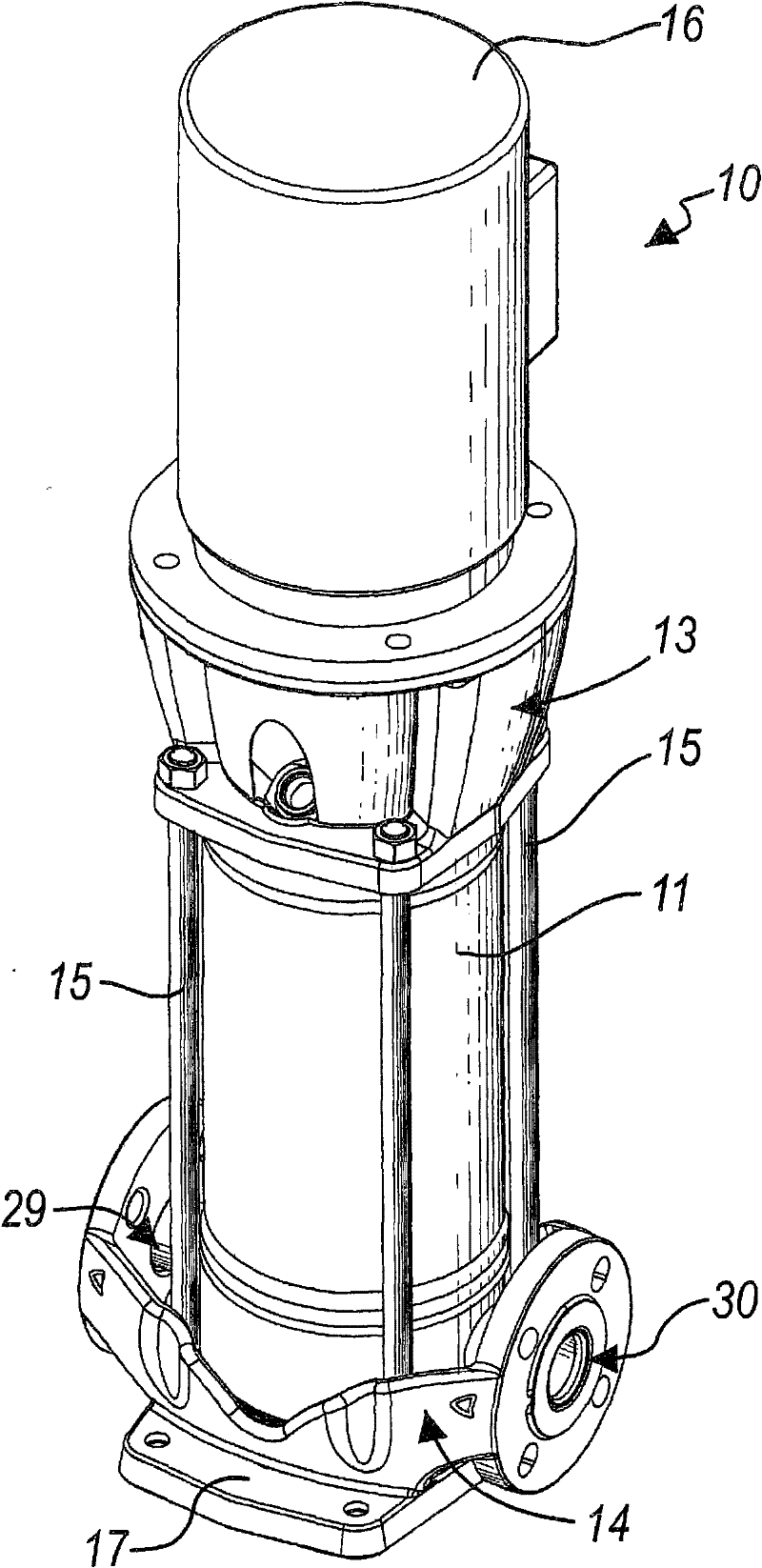

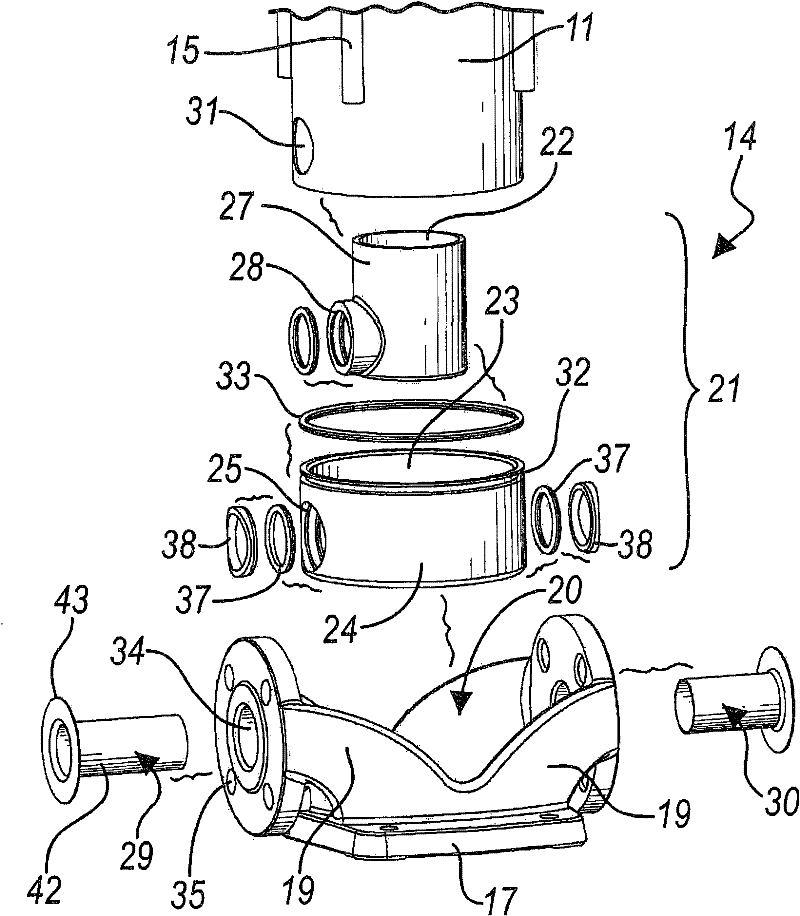

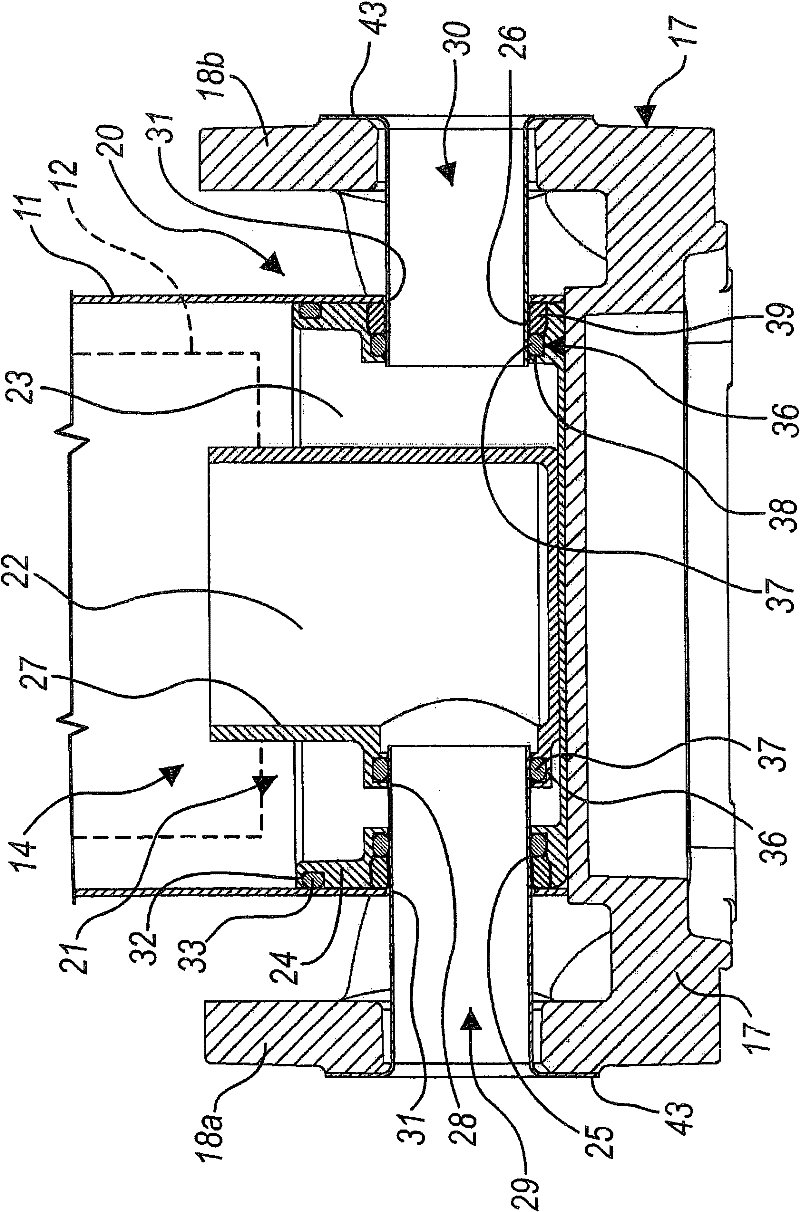

[0025] Referring to the drawings, a hydraulic pump according to the invention is indicated generally by the reference numeral 10 .

[0026] The hydraulic pump 10 includes a casing 11 for containing an impeller assembly 12 in image 3 is schematically shown in dotted lines in ; in this embodiment, the pump is a multistage vertical pump and the impeller assembly corresponds to the multistage impeller.

[0027] The casing 11 (which has a cylindrical shape) is closed at its ends by a top cover 13 and a pump body 14 for connecting to a hydraulic system, respectively, as in figure 2 clearly visible in.

[0028] The top cover 13 and the connecting pump body 14 are connected by tension elements 15 in a manner known per se.

[0029] The motor 16 is externally fixed to the top cover 13 and its outer shaft passes through the top cover 13 to connect with the impeller assembly 12 inside the casing 11 .

[0030] According to the invention, the connecting pump body 14 comprises a base 17...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com