Anti-glare film, its preparation method and display device using the anti-glare film

An anti-glare film and anti-glare layer technology, applied in chemical instruments and methods, transportation and packaging, instruments, etc., can solve problems such as deterioration of anti-glare properties, suppress white turbidity, improve surface roughness, and reduce protrusions Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

[0101] (1-1) Structure of liquid crystal display device

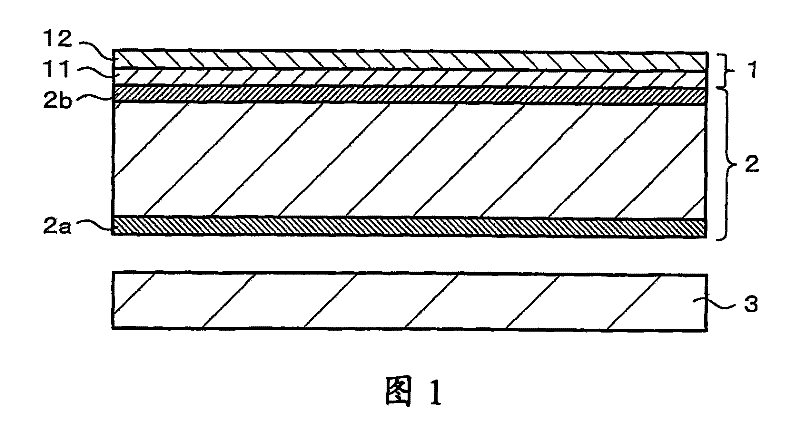

[0102] figure 1 An example of the configuration of the liquid crystal display device according to the first embodiment of the present invention is shown. Such as figure 1 As shown, the liquid crystal display device has a liquid crystal panel 2 and a light source 3 disposed directly below the liquid crystal panel 2 . This liquid crystal panel 2 has an antiglare film 1 on its display side.

[0103] This light source 3 is used to supply light to the liquid crystal panel 4 and has, for example, a fluorescent lamp (FL), EL (Electro Luminescence), LED (Light Emitting Diode), or the like. The liquid crystal panel 2 is used for temporally and spatially adjusting the light provided by the light source 3 and displaying information. Polarizing plates 2 a and 2 b are provided on both surfaces of the liquid crystal panel 2 . Each of the polarizing plates 2a and 2b allows only one of the vertically crossing polarized light com...

no. 2 approach

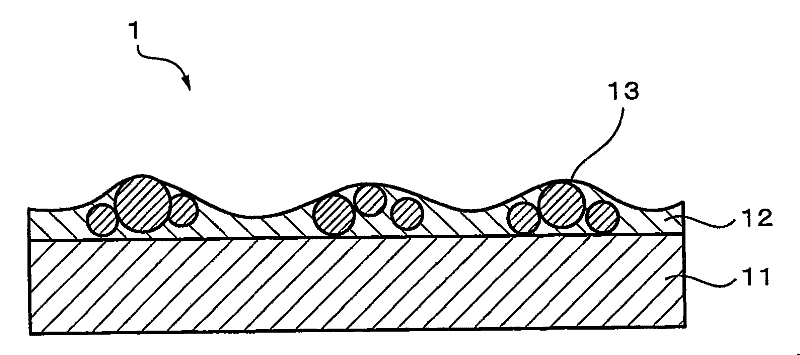

[0157] (2-1) Structure of anti-glare film

[0158] Figure 4 An example of the configuration of the antiglare film 10 according to the second embodiment of the present invention is shown. In the antiglare film 10 , an antiglare layer 12 containing fine particles 13 is formed on a base material 11 , and a transparent resin layer 14 having translucency is formed on the antiglare layer 12 . The base material 11, the antiglare layer 12, and the fine particles 13 are similar to those in the first embodiment described above. On the surface of the anti-glare layer 12, a fine concavo-convex shape utilizing convection and aggregation of the fine particles 13 is formed.

[0159] A transparent resin layer 14 is laminated onto the anti-glare layer 12 , which is a layer whose refractive index is smaller than that of the anti-glare layer 12 , for example, so as to reduce the reflectance of the surface. The transparent resin layer 14 is formed along the antiglare layer 12, for example, and ...

Embodiment 1

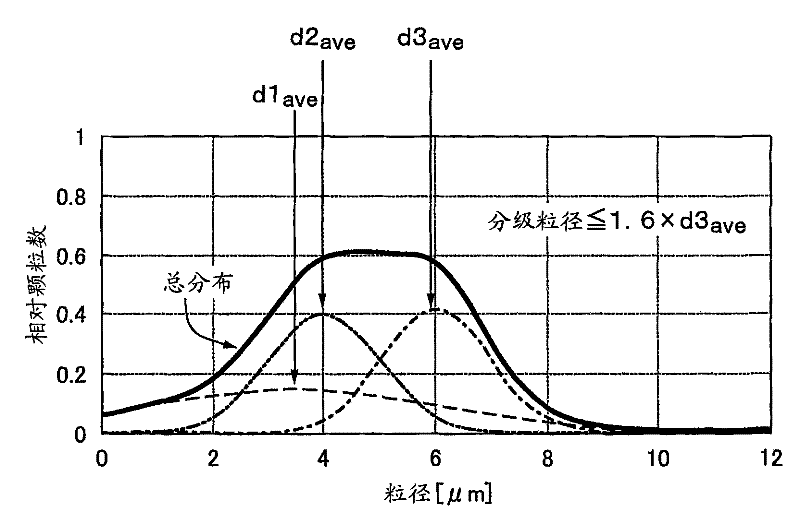

[0184] First, as fine particles, crosslinkable styrene pellets SBX6 (manufactured by SEKISUI PLASTICS CO., LTD.) having a center particle size equal to about 6 μm were separated by fine powder Classification is carried out by mechanical method, and the fine particles above 10μm are removed. The average diameter of the fine particles obtained after the classification process was equal to 6.3 μm, the median diameter was equal to 5.5 μm, and the coefficient of fluctuation was equal to 31%.

[0185] Next, raw materials of the following coating composition were mixed by using the fine particles obtained after the classification process. The dope was stirred for one hour with a magnetic stirrer, and filtered through a 20 μm sieve having a roughness equal to or greater than three times the average diameter. After that, one surface of a triacetate cellulose (TAC) film (manufactured by Fuji Photo Film Co., Ltd.) having a thickness of 80 μm was coated with the resulting paint by a bar ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com