Vibration disc for delivering screw blank of high-speed multi-pivot device

A technology of guiding device and conveying screw, which is applied in the direction of conveyor, feeding device, measuring device, etc., which can solve the problems that the vibrating plate cannot be matched and multiple feeding can not be completed at the same time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

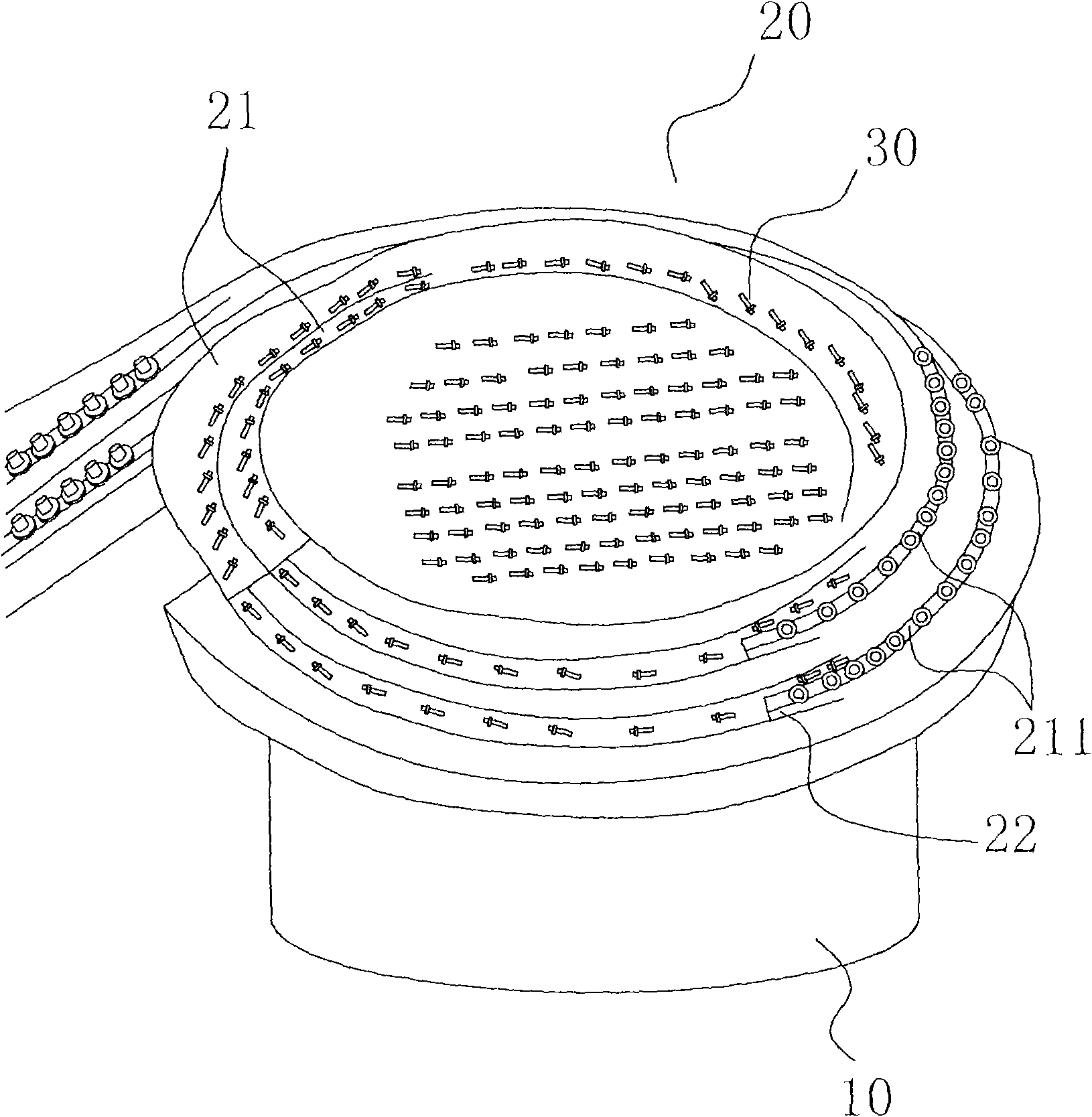

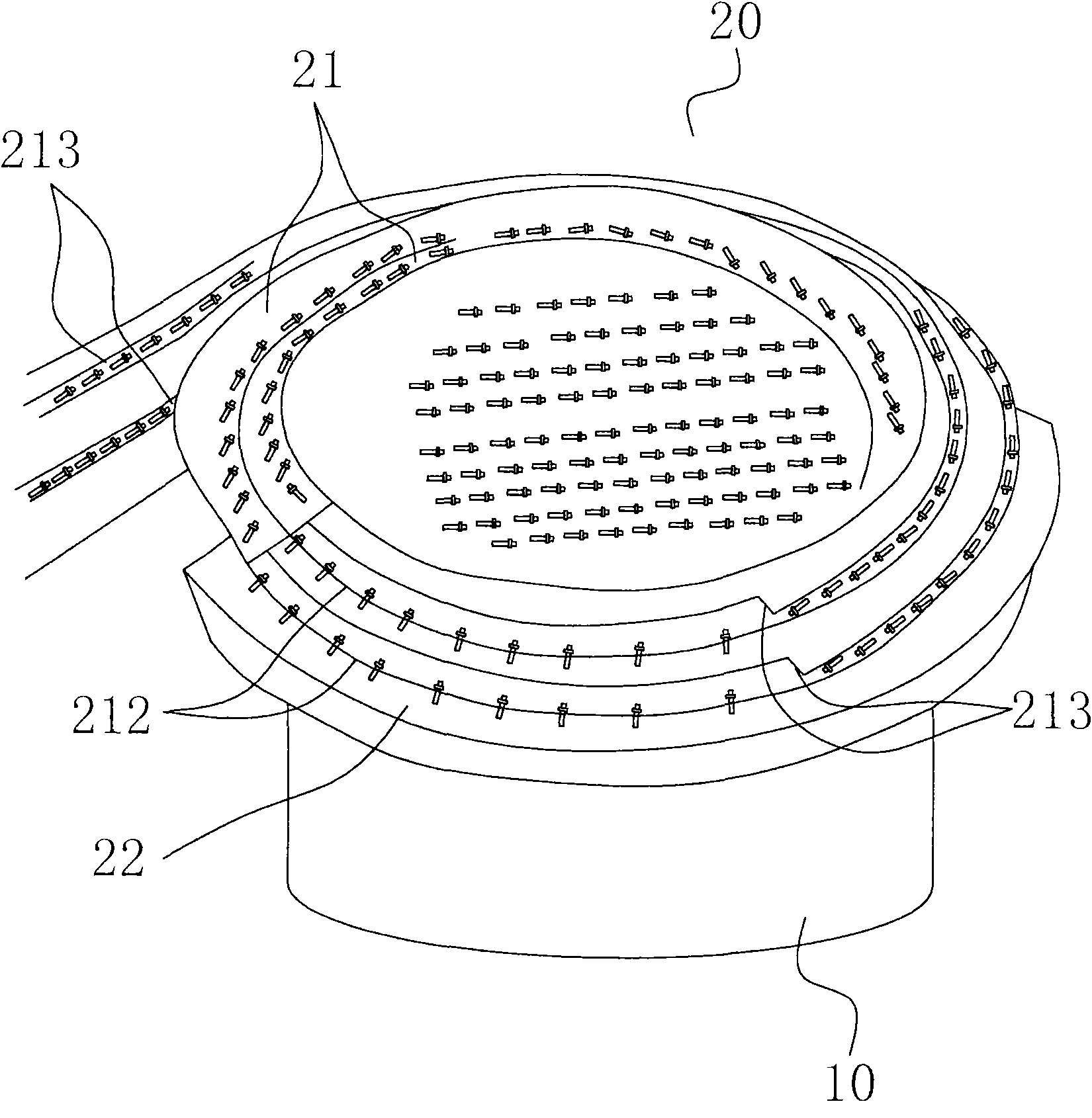

[0016] Such as Figure 1-2 The present invention shown includes a vibrator 10 and a disc body 20 installed on the vibrator 10, a feeding track 21 is arranged in the disc body 20, and two or more There are more than two guiding devices 22, and the guiding devices 22 have a structure that makes the arrangement direction of the screw blanks 30 on the feeding track 21 consistent.

[0017] The disc body 20 is provided with two or more tracks for feeding screw blanks 30 .

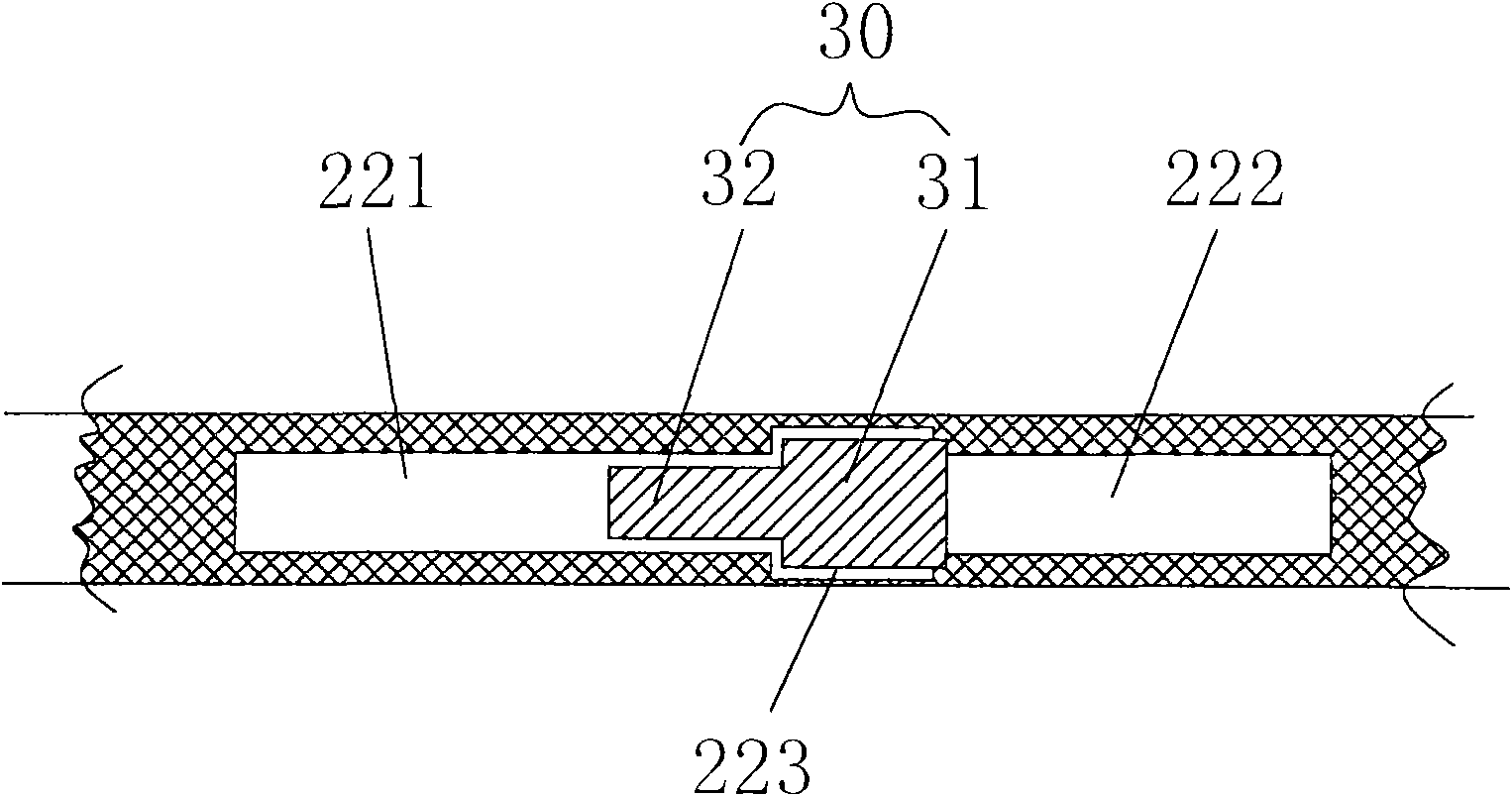

[0018] The guide device 22 has a structure for feeding the screw blank 30 upright in the disc body 20. The screw blank 30 to be fed is placed in the cavity in the middle of the disc body 20, and the feeding track 21 is circled upward along the cavity. The middle part of the feeding track 21 is divided into two or more than two tracks for feeding, each track is provided with a groove 211, and the screw blank 30 is vertically inserted in the groove 211 and arranged closely to feed.

[0019] The guide device 22 ha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com