Deck unit erection gantry

A cable-mounted crane and hoist technology, which is applied in the field of cable-mounted cranes, can solve the problems of difficult operation, numerous moving procedures, huge winch and wire rope hoisting system, etc., and achieves the effects of convenient operation, low cost and reasonable stress.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

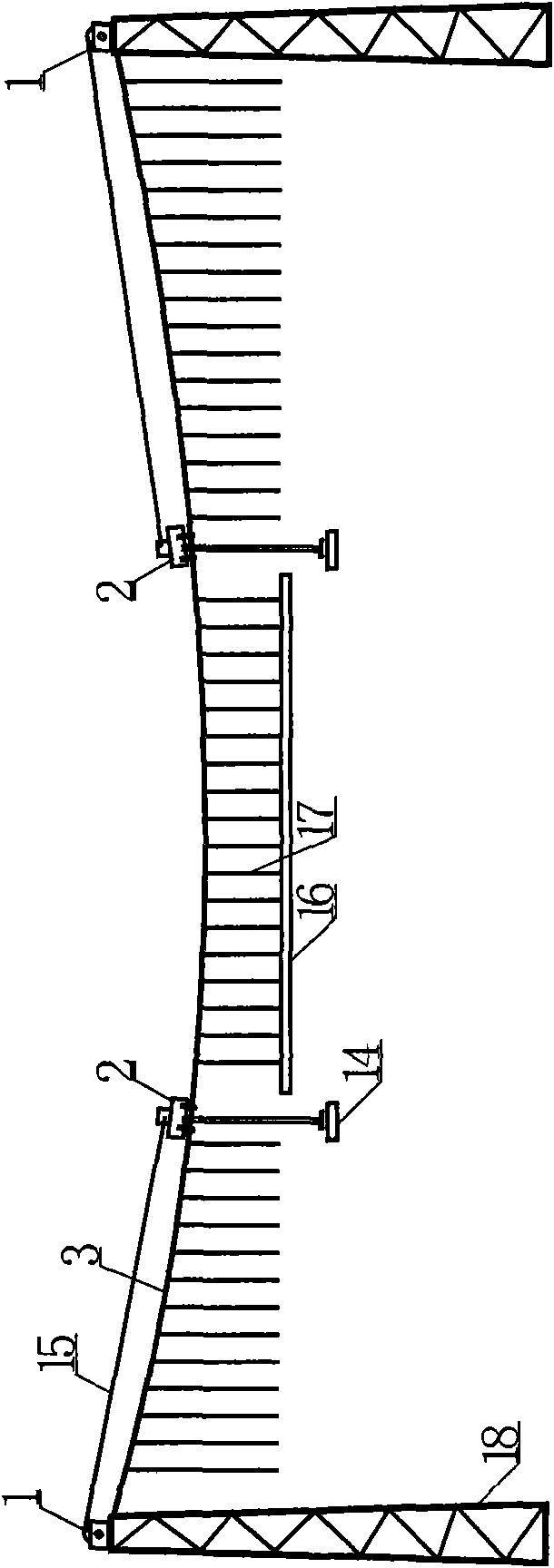

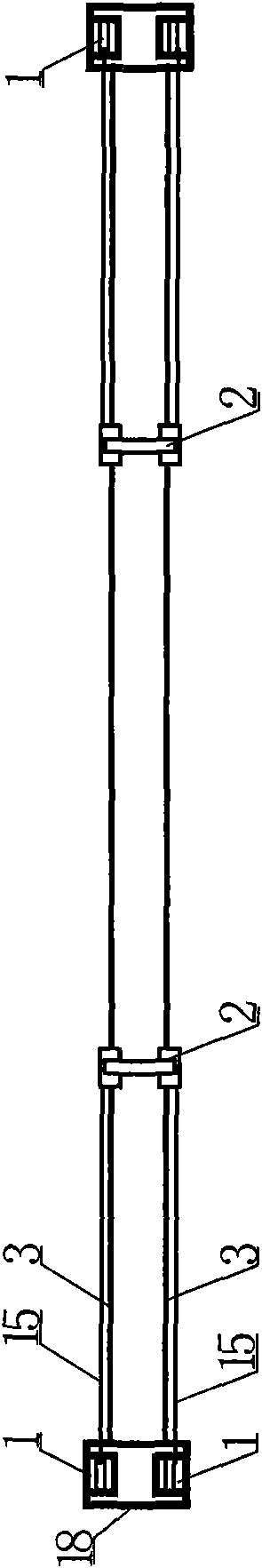

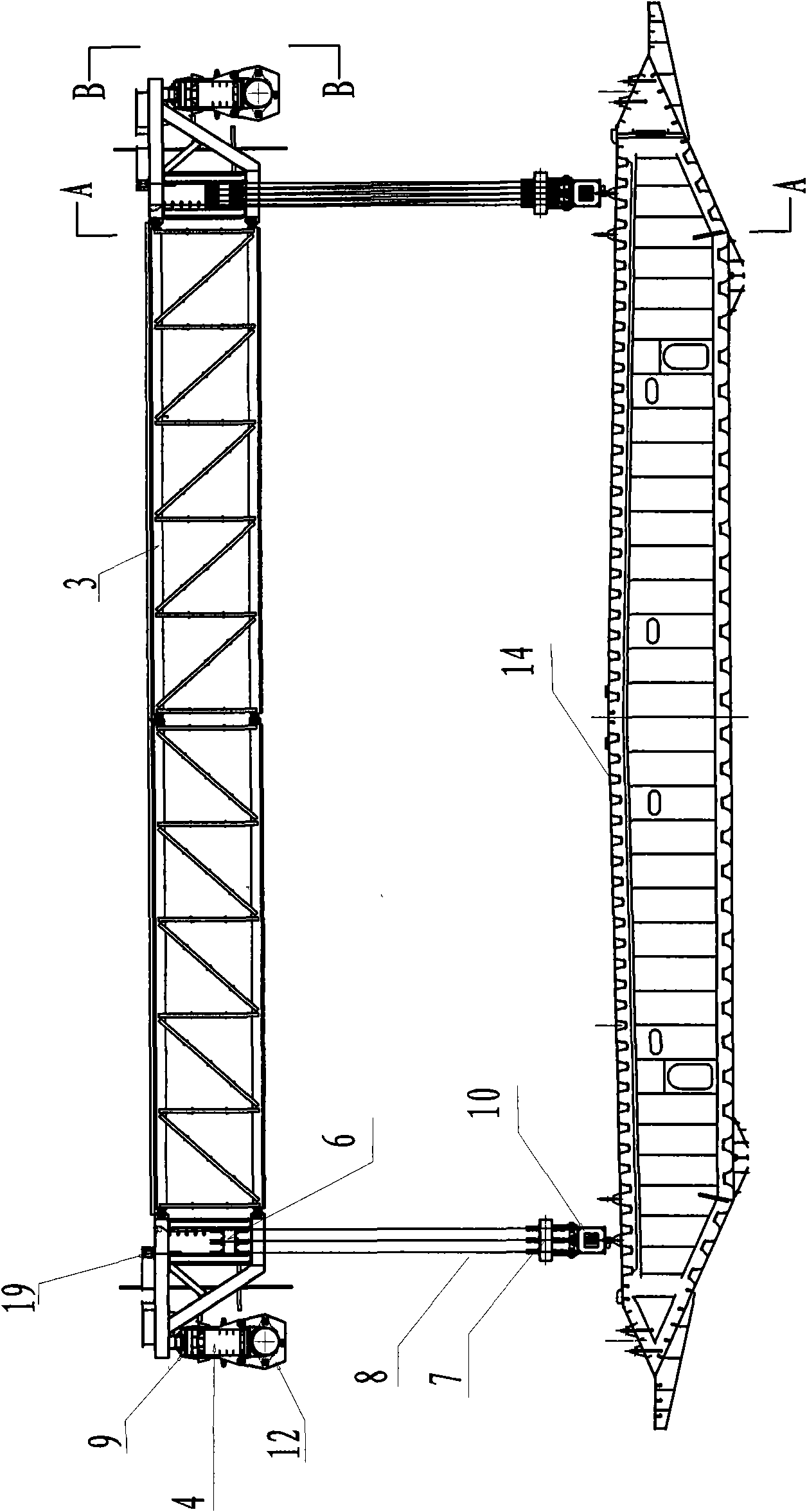

[0021] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 As shown, a cable-loaded crane includes two towers 18, a hoist 1, a lifting block 2, and a load-bearing cable 3. The hoist 1 is located on the top of the tower 18, and the load-bearing wire 3 and the two towers 18 The top of the hoist 1 drives the lifting block 2 to slide along two parallel bearing cables 3 through the traction rope 15. The lifting block 2 is composed of two end beams 4, a load beam 5, a fixed pulley 6, The movable pulley 7 is composed of a fixed pulley 6 arranged on the load-bearing beam 5, and a suspension rope 8 is wound on the fixed pulley 6 and the movable pulley 7. The two ends of 5 form a steel pin hinged connection form with the end beam 4 through the hinge base 9; The connection point is located at the center of gravity of the shoulder pole beam 10, and the purpose is to hoist the suspended object, that is, the steel box girder section 14 horizontally. The two ends of the loa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com