Stacked electric cloth drop storage and transport vehicle and its use method

A layered, drop-clothing technology, applied in the directions of transportation and packaging, winding strips, thin material handling, etc., can solve the problems of high labor intensity and low work efficiency of workers, and achieve low labor intensity, convenient movement, and storage capacity. big effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

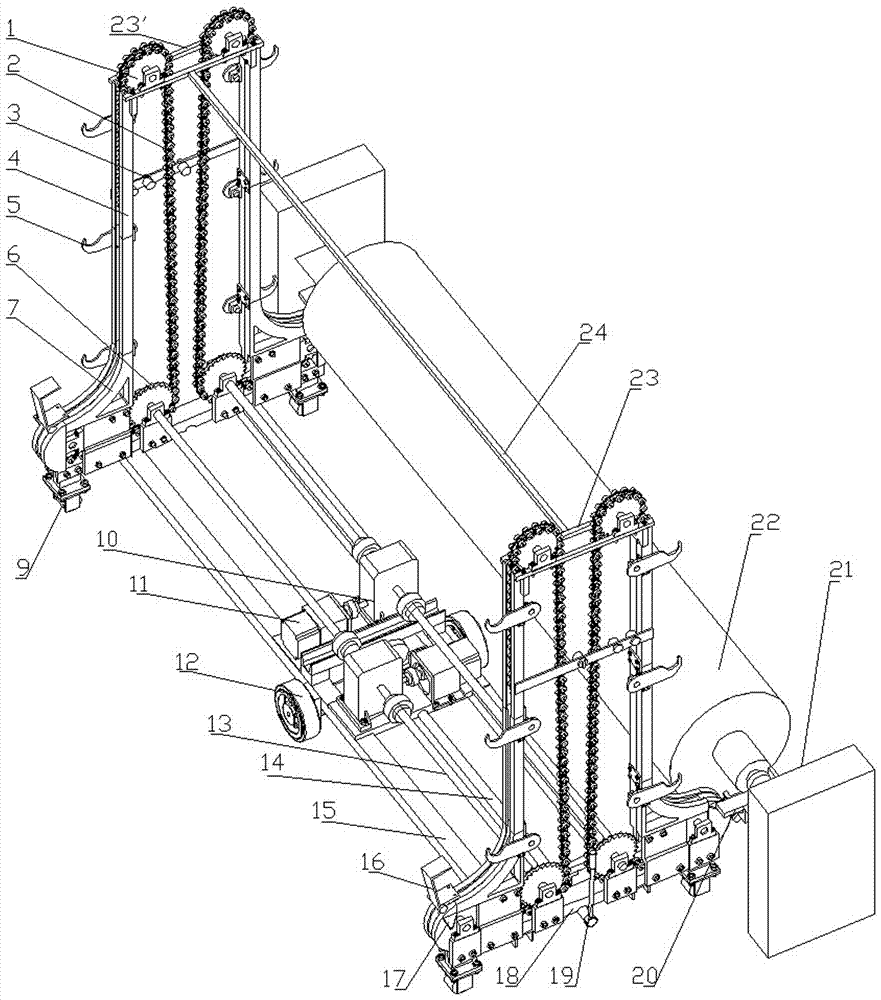

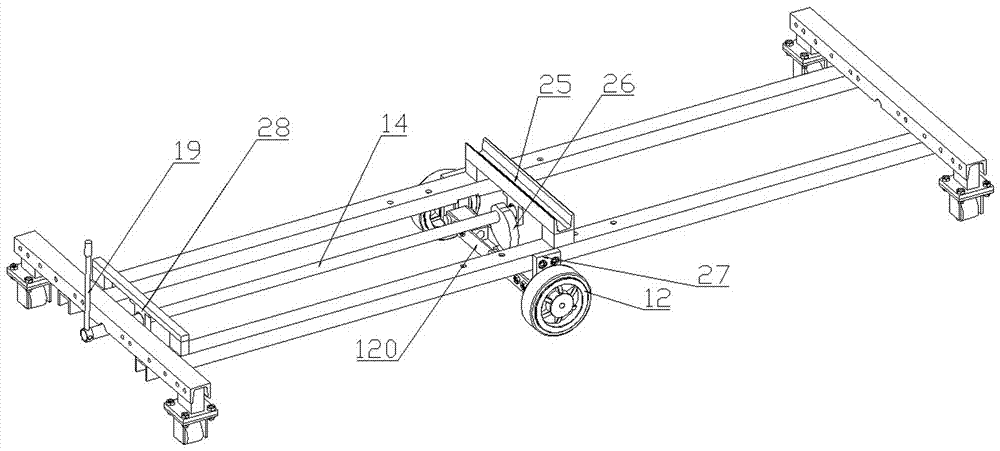

[0025] The present invention will be further described below in conjunction with the accompanying drawings.

[0026] like Figure 1 to Figure 5 It can be seen that the stacked electric cloth drop storage and transportation vehicle of the present invention includes a vehicle frame, and a running device is arranged below the vehicle frame, and it is characterized in that a group of cloth drop lifting devices are respectively provided on both sides of the vehicle frame, for Drop the cloth from the loom and lift the cloth roll upwards; both sides of the frame are provided with at least one set of cloth roll storage devices for storing the lifted cloth roll; it also includes matching with the cloth drop lifting device drive unit.

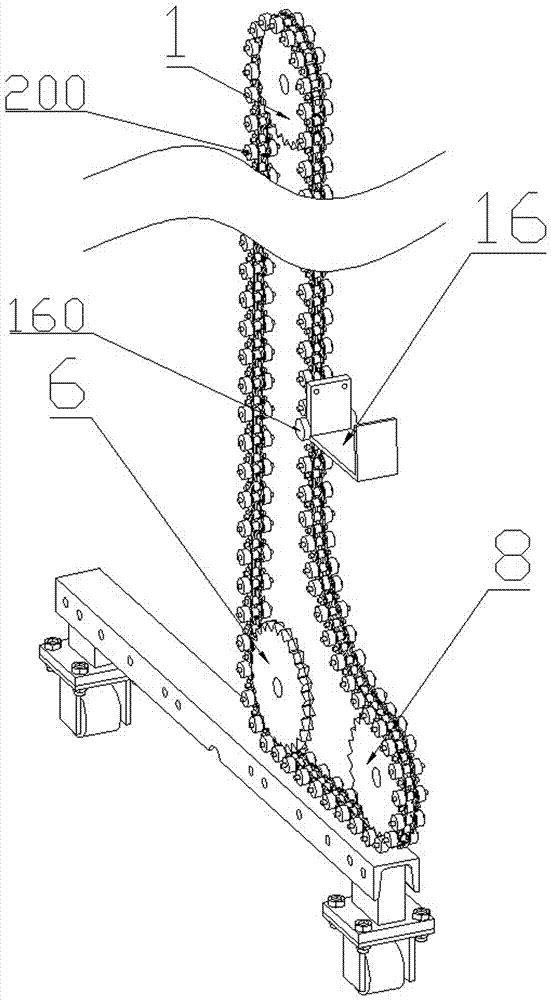

[0027] The falling cloth lifting device includes a sprocket set respectively arranged at two ends of the vehicle frame, and the sprocket set includes a driving sprocket 6, a driven sprocket A1, a driven sprocket B8, and the driving sprocket 6, driven sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com