Intermediate casing of turbojet

A turbojet, intermediate box technology, applied in engine components, machines/engines, jet propulsion, etc., can solve problems such as large size and damage to engine aerodynamic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

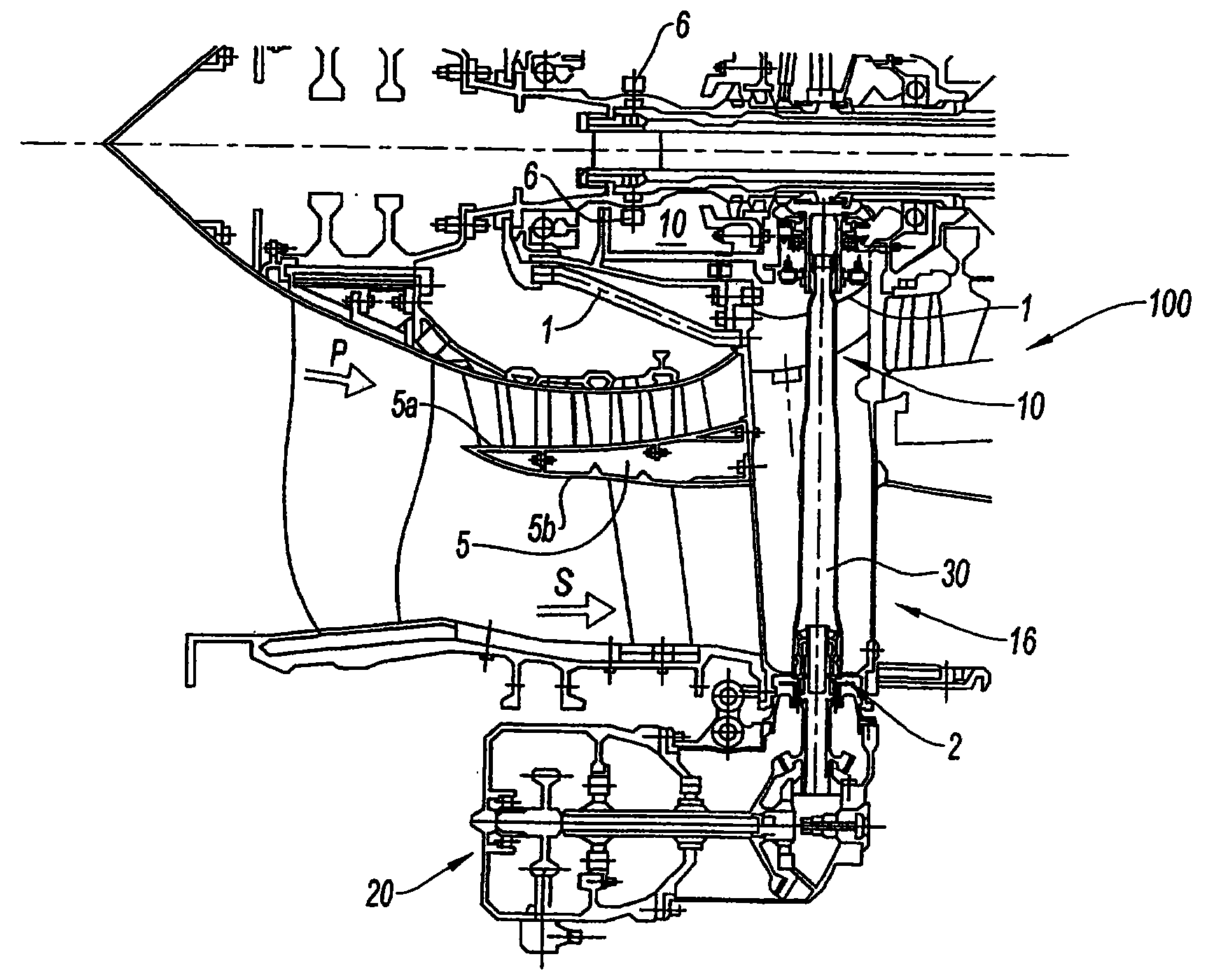

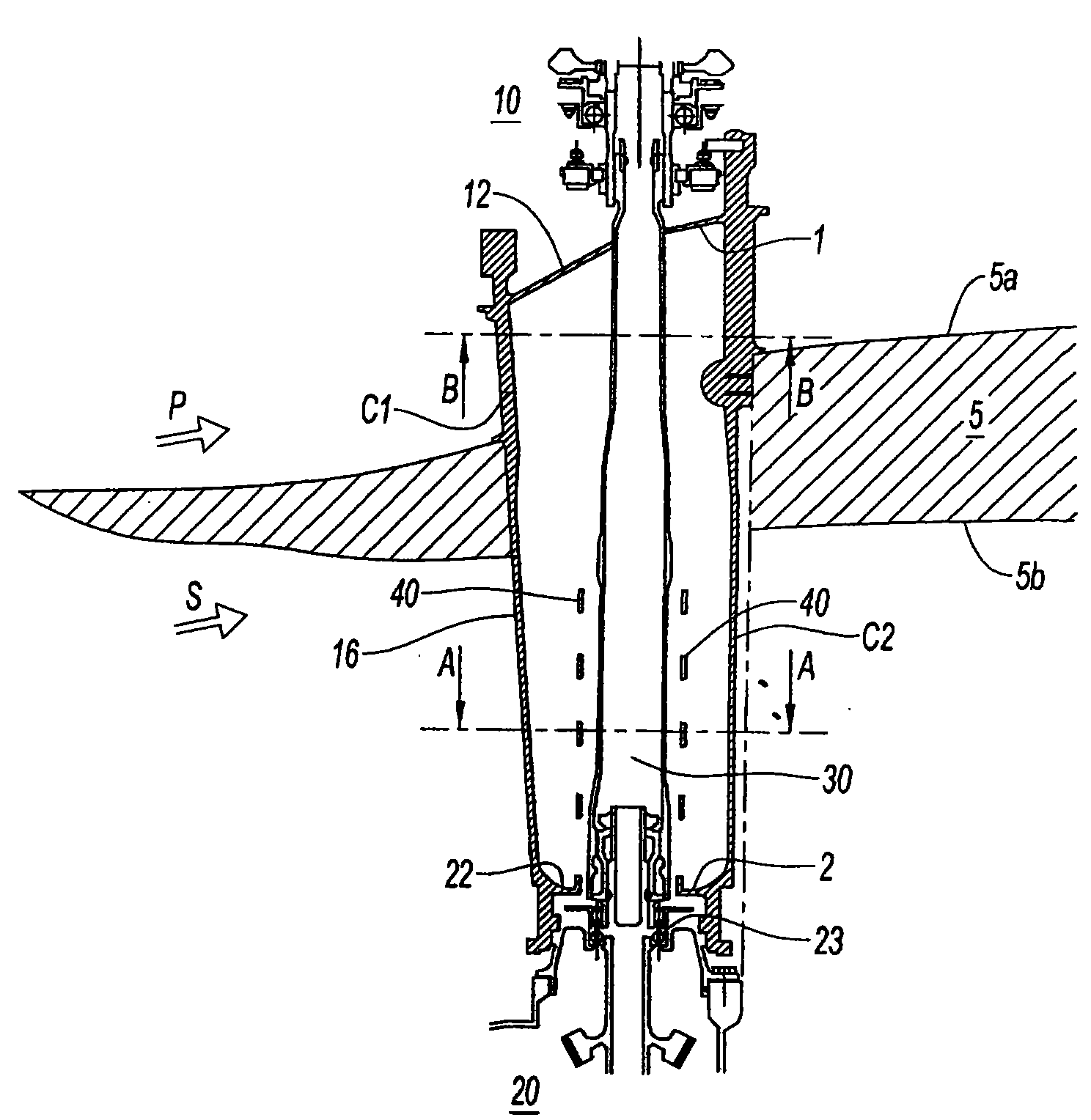

[0030] An embodiment of the present invention is now described with reference to the accompanying drawings: figure 2 Shown is an intermediate box 100 with a central hub 1 and an outer casing 2 connected by a radial arm 16 arranged vertically on the lower part. This central hub 1 partly delimits the volume of the turbojet engine's front wall 10 in which the bearings 6 supporting the low pressure (BP) and high pressure (HP) rotor shafts are housed. An auxiliary machine drive box 20 is mounted on the cylindrical outer casing 2 of the box 100, these auxiliary machines are driven by an integral transmission shaft 30 mounted in the radial lever arm 16 for obtaining the Power supported on the BP and HP rotor shafts in the front wall 10.

[0031] A separator 5 delimits the second gas flow S and the first gas flow P. The separator is formed by two annular walls 5a, 5b separated by a radial arm 16 through which the cross-section of the first air flow is smaller relative to the cross-...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap