Open and close door of electric oven

An electric oven and closed door technology, applied in the field of opening and closing doors, can solve the problems of failing to meet safety standards, high cost of solutions, difficult technical implementation, etc., and achieve the effects of lowering temperature, convenient opening, and good thermal insulation effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

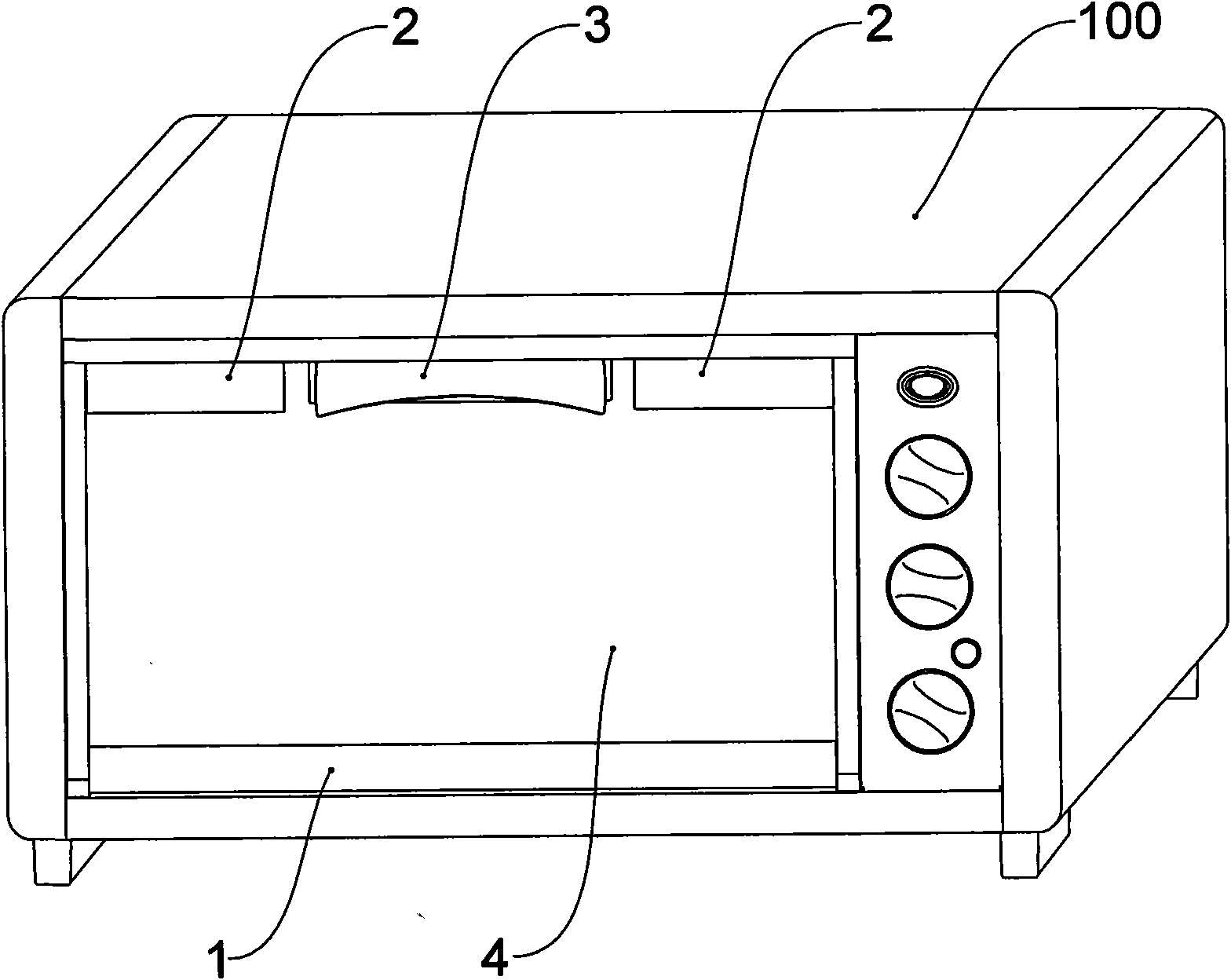

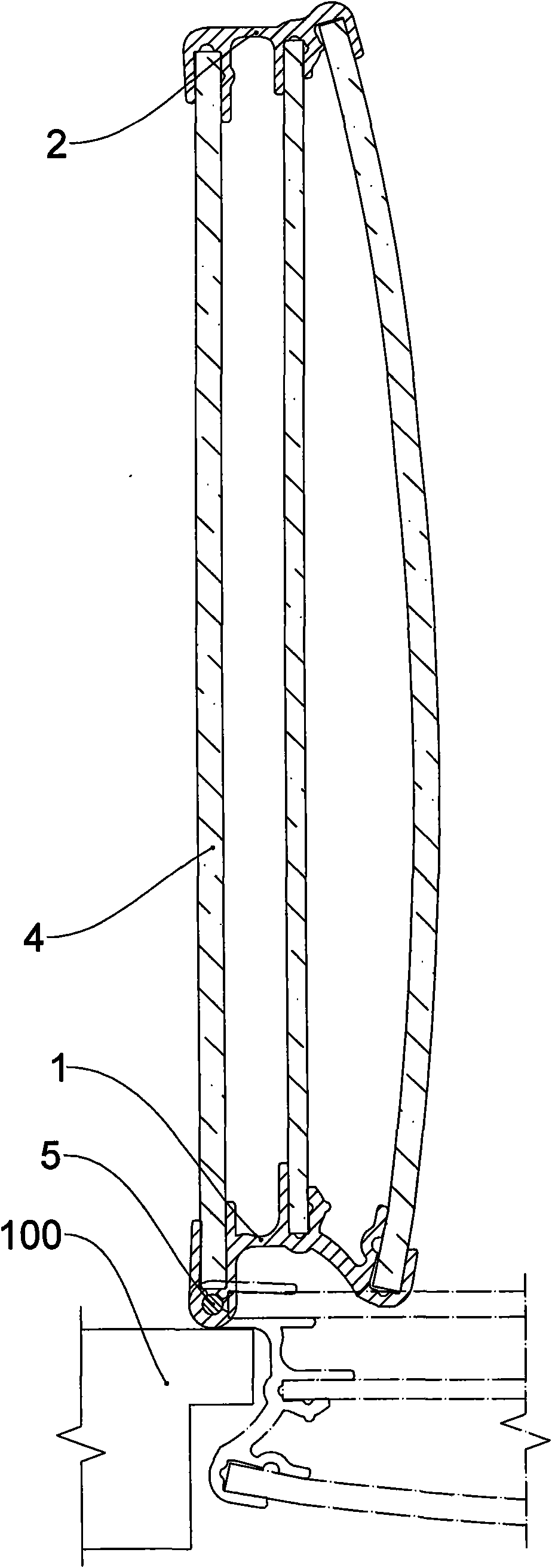

[0031] Such as figure 1 , image 3 , Figure 4 , Figure 6 , Figure 7As shown, the electric oven of this embodiment has a heating cavity, which is the most common electric oven. The opening and closing door of the electric oven includes a first clamping part 1, a second clamping part 2, a handle 3, a door panel 4. The rotating shaft 5, the first clamping part 1 and the second clamping part 2 are respectively fixedly connected with the two opposite upper and lower sides of the door panel 4, and the first clamping part 1 is located at the The lower side of the door panel 4, the second clamping part 2 is located on the upper side of the door panel 4, the first clamping part 1 is rotatably connected with the box body 100 of the electric oven through the rotating shaft 5, and the The rotating shaft 5 is placed horizontally and horizontally, so the opening and closing door of this embodiment is in the form of opening up and down. The first clamping part 1 and the second clampin...

Embodiment 2

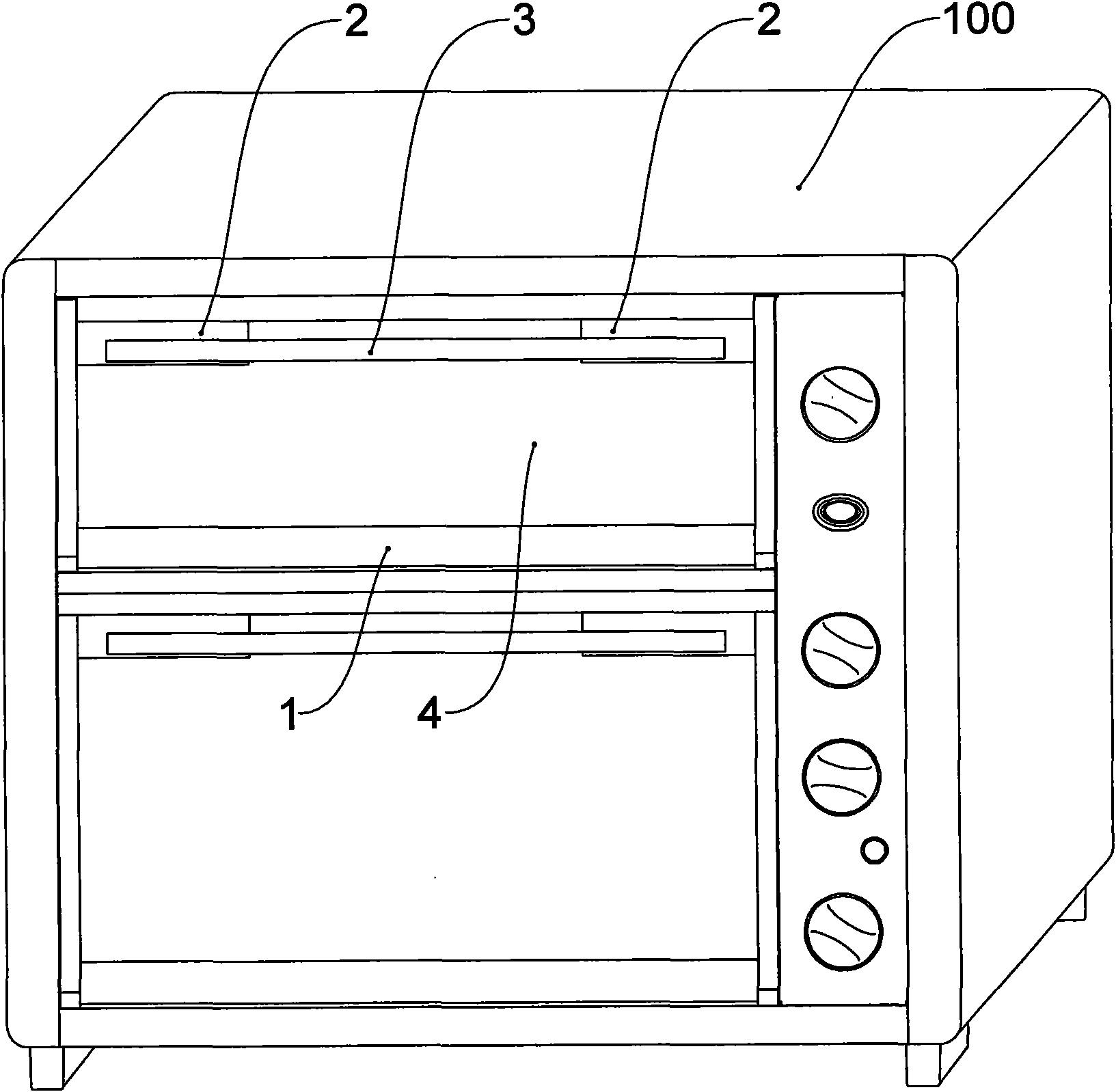

[0034] Such as figure 2 , image 3 , Figure 5 to Figure 9 As shown, the difference between this embodiment and Embodiment 1 is that the electric oven of this embodiment has two heating chambers up and down, so it has two opening and closing doors. In addition, the handle 3 is a cross bar and is fixedly connected On the two second clamping parts 2, the first clamping part 13 on the outermost side of the first clamping part 1 of the upper opening and closing door and the first clamping part 12 in the middle There is no relative dislocation between them, which is more conducive to avoiding the box in the middle of the two heating chambers, so the upper and lower opening and closing doors will not be interfered by the box 100, and they can be opened freely. The structure and implementation of the lower opening and closing doors Example 1 is the same.

[0035] The remaining features of this embodiment are the same as those of Embodiment 1.

Embodiment 3

[0037] Such as Figure 10 , Figure 11 As shown, the difference between this embodiment and Embodiment 1 is that the rotating shaft 5 of this embodiment is vertically placed, so the opening and closing door of this embodiment is in the form of left and right horizontal opening, and the outermost and innermost The door panels 4 are all arc-shaped panels, and the door panel 4 in the middle is a flat plate. The cross-sectional shapes of the first clamping part 1 and the second clamping part 2 are also different from those of the first embodiment. The cross-sectional shapes of the first clamping part 1 and the second clamping part 2 are symmetrical, and each of the door panels 4 protrudes from the outside of the box body 100, and the three-dimensional shape of the shape is more visually impactful, and the shape beautiful.

[0038] The remaining features of this embodiment are the same as those of Embodiment 1.

[0039] Of course, the number of the door panels 4 in the present i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com