Failure null transition device for hot-rolling finishing mill

A technology of finishing mill and hot continuous rolling, which is applied in the field of transitional devices for failure of hot continuous finishing mill, and can solve problems such as stack rolling or piled steel production accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

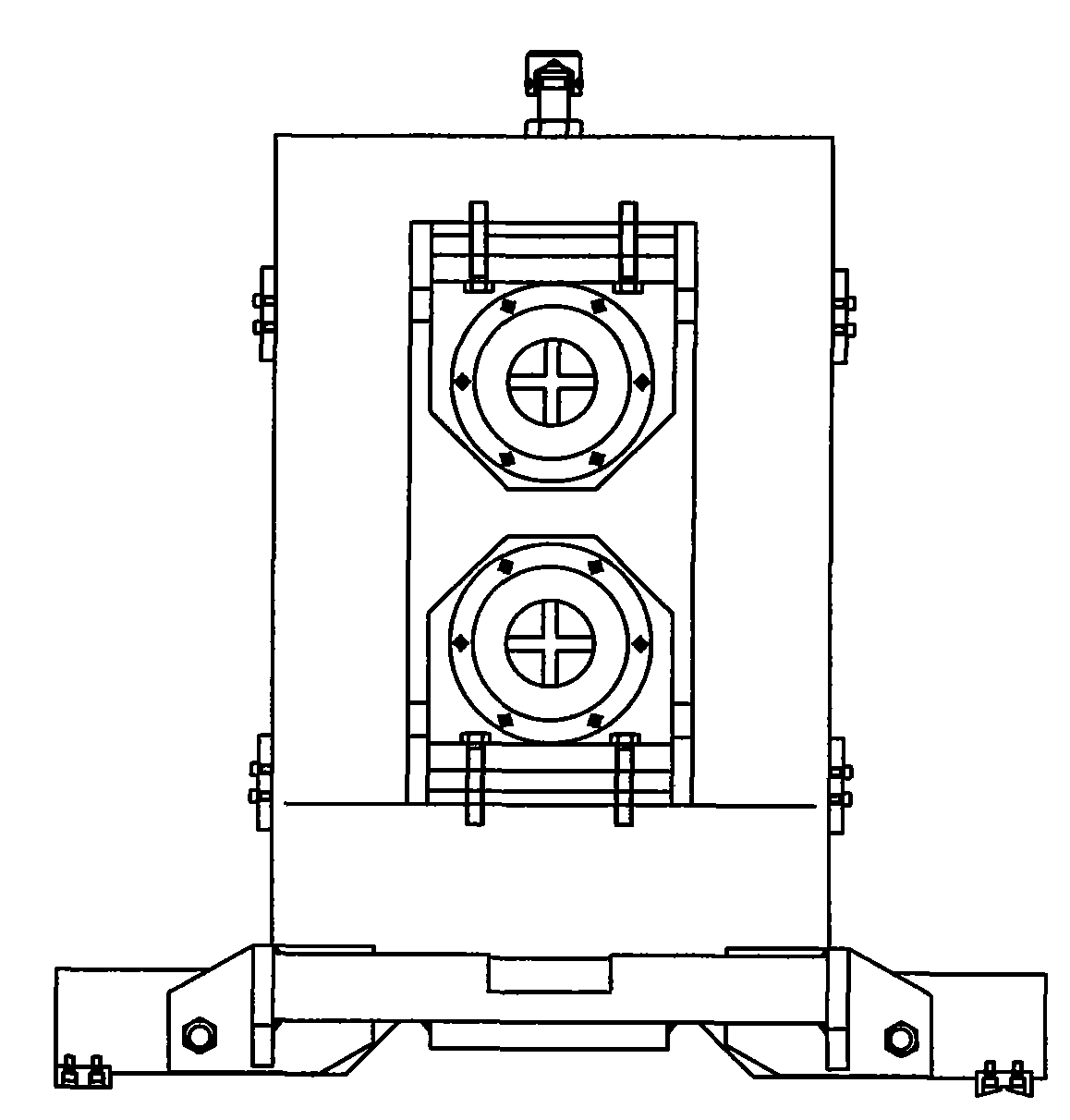

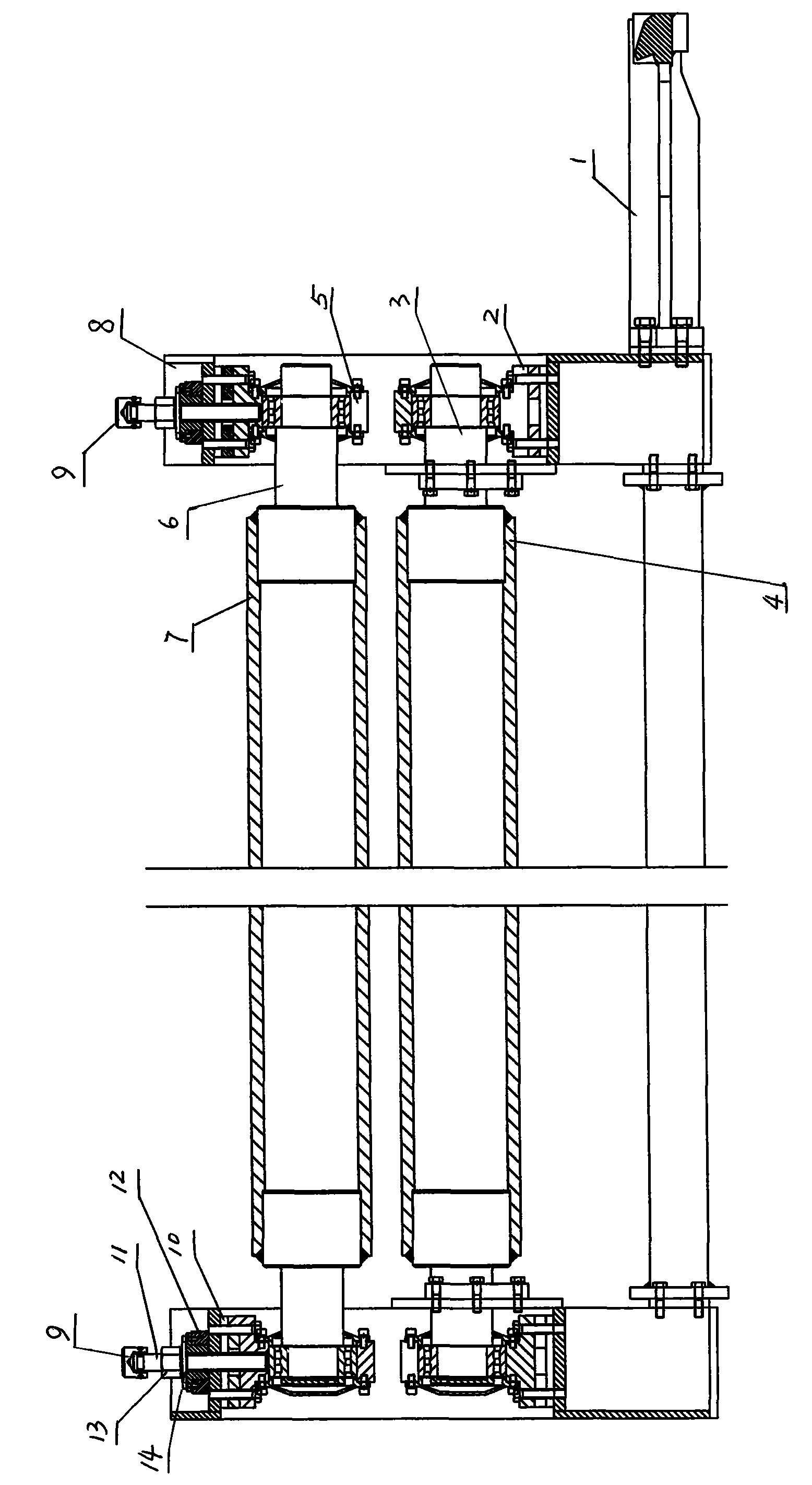

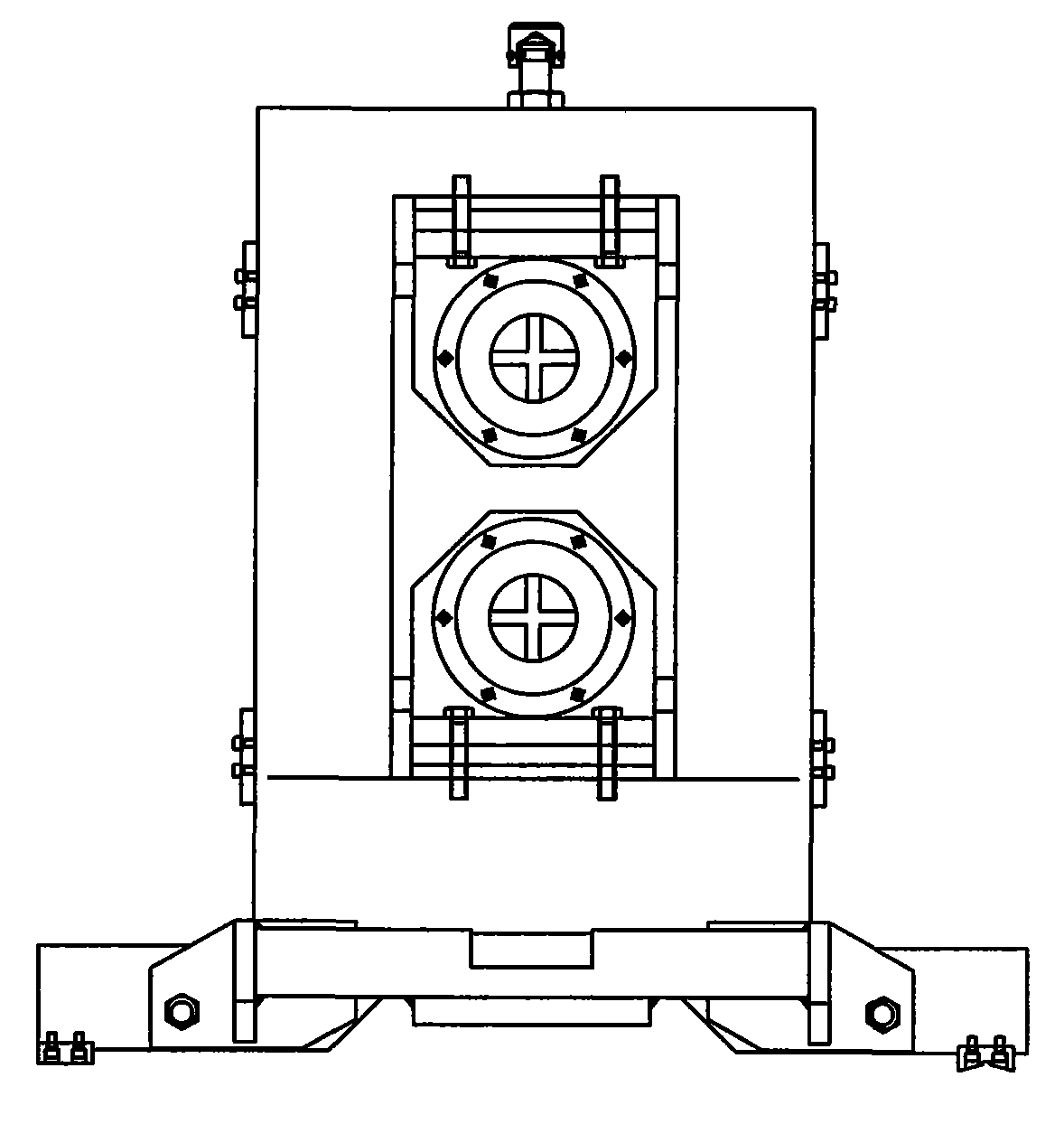

[0012] Embodiment 1: As shown in Fig. 1, Fig. 2 and Fig. 3, this embodiment includes an upper mandrel 6 and a lower mandrel 3, which is characterized in that the upper mandrel 6 is arranged above the lower mandrel 3, and the upper mandrel 6 is covered There is an upper roller sleeve 7, the lower mandrel 3 is covered with a lower roller sleeve 4, the shaft head of the upper mandrel 6 is arranged on the bearing, and the shaft head of the lower mandrel 3 is arranged on the bearing, the bearings are all sliding bearings, and the bearings are uniform. Set on the bearing seat (lower bearing seat 2, upper bearing seat 5), set the bearing seat of the upper mandrel 6 as the upper bearing seat 5, the upper bearing seat 5 is fixedly installed on the bracket 8, and set the bearing seat of the lower mandrel 3 It is the lower bearing seat 2, the lower bearing seat 2 is fixedly arranged on the support 1, and the bracket 8 is fixedly installed on the lower bearing seat 2, that is, the lower be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com