Loading method of pile foundation vertical static load test

A load test and vertical technology, which is applied in the direction of basic structure test, basic structure engineering, construction, etc., can solve the problems of unsuitable use, high cost, slow speed, etc., and achieve the effect of low cost, wide applicability and fast loading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

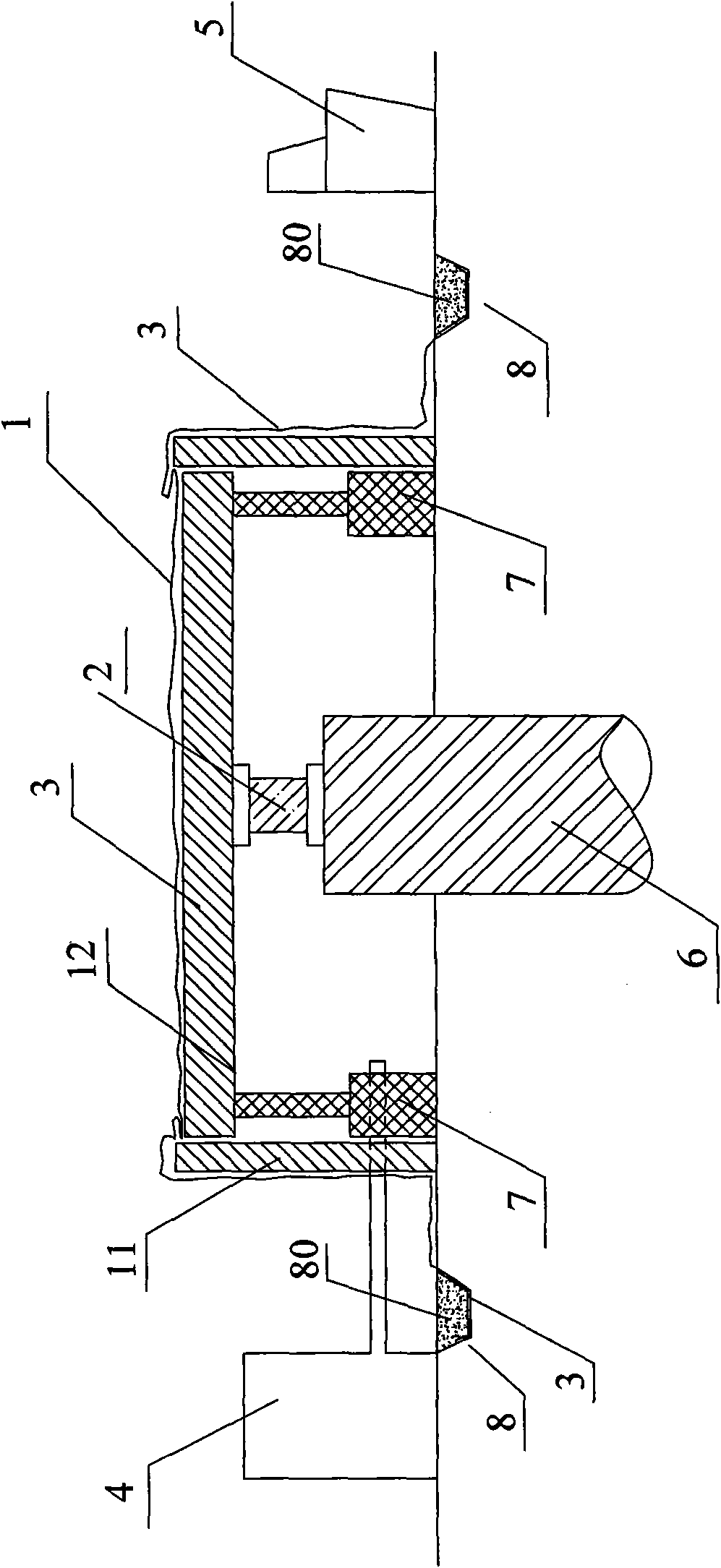

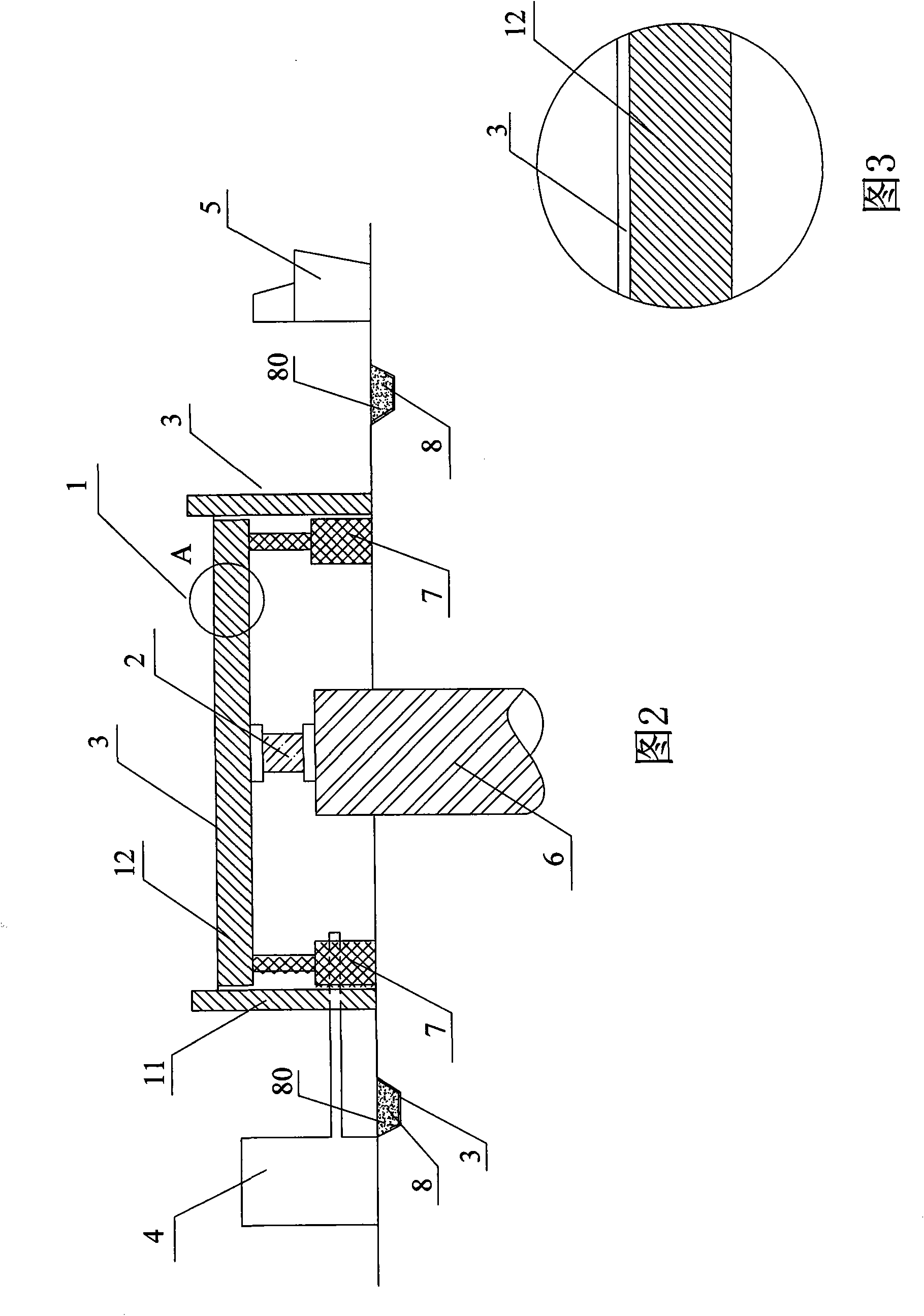

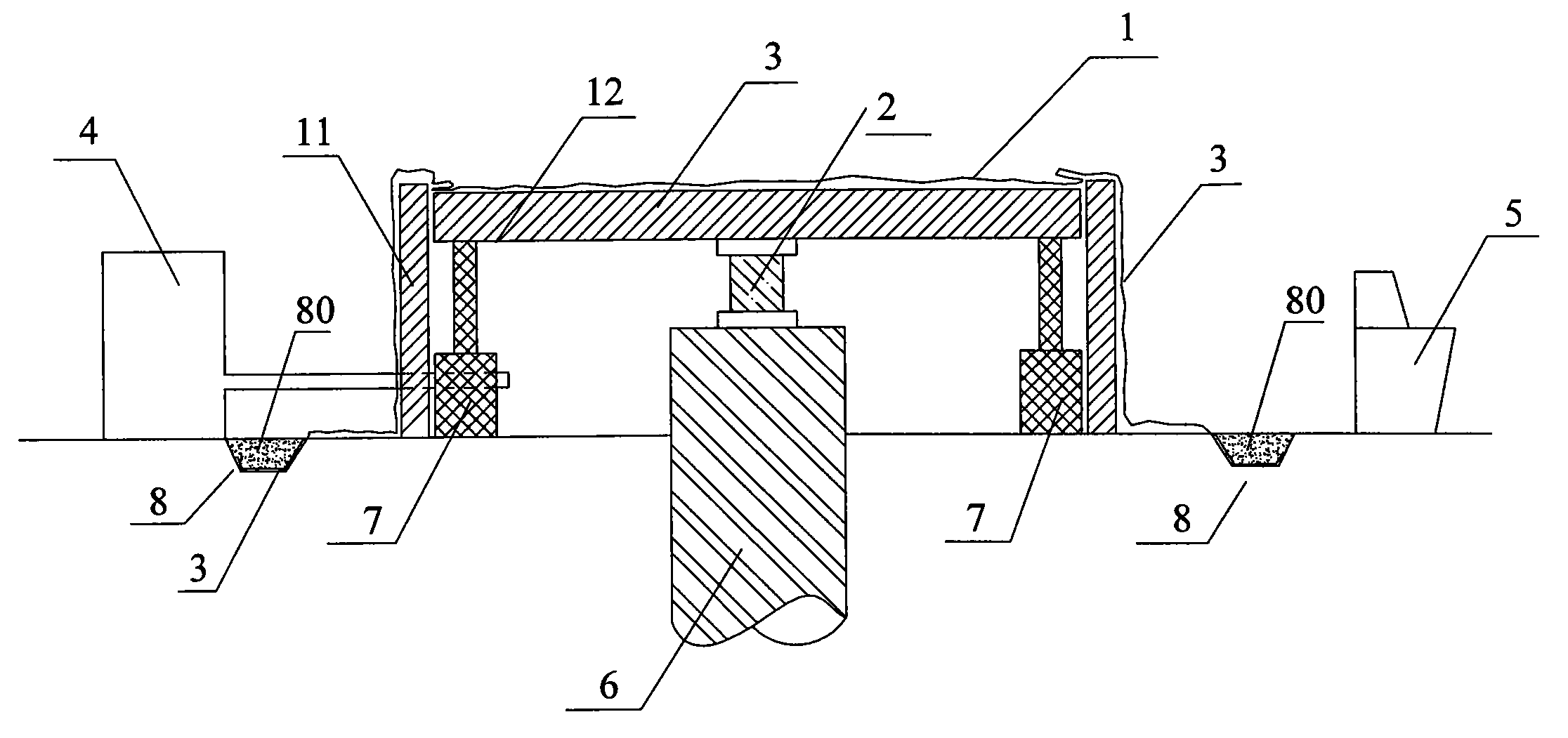

[0016] Refer to attached figure 1 with 2 . A kind of loading method of pile foundation vertical static load test provided by the present invention, comprises the following steps successively:

[0017] (1) Installation of static load loading support mechanism 1 . The static load supporting mechanism 1 includes a side wall structure 11 and a liftable roof structure 12 . First install the side wall structure 11 of the static load loading support mechanism so that the center of the test pile body 6 coincides with the center of the static load loading support mechanism; then install the liftable top cover structure 12 of the static load loading support mechanism, and place the pressure sensor 2 placed between the roof structure 12 and the pile top.

[0018] (2) A closed compressible space is formed on the ground, and the static load loading support mechanism is included; in this embodiment, the sealing film 3 is used, that is, the sealing film is covered on the support mechanis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com