A Soil High Pressure Rotary Sprinkling Restoration Process and Device

A high-pressure rotary spray and soil technology, applied in the field of soil remediation, can solve problems such as poor remediation effect, and achieve the effects of reducing equipment movement and adjusting position, quick dispersion and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043]Soil high-pressure rotary spraying restoration process, including the following steps:

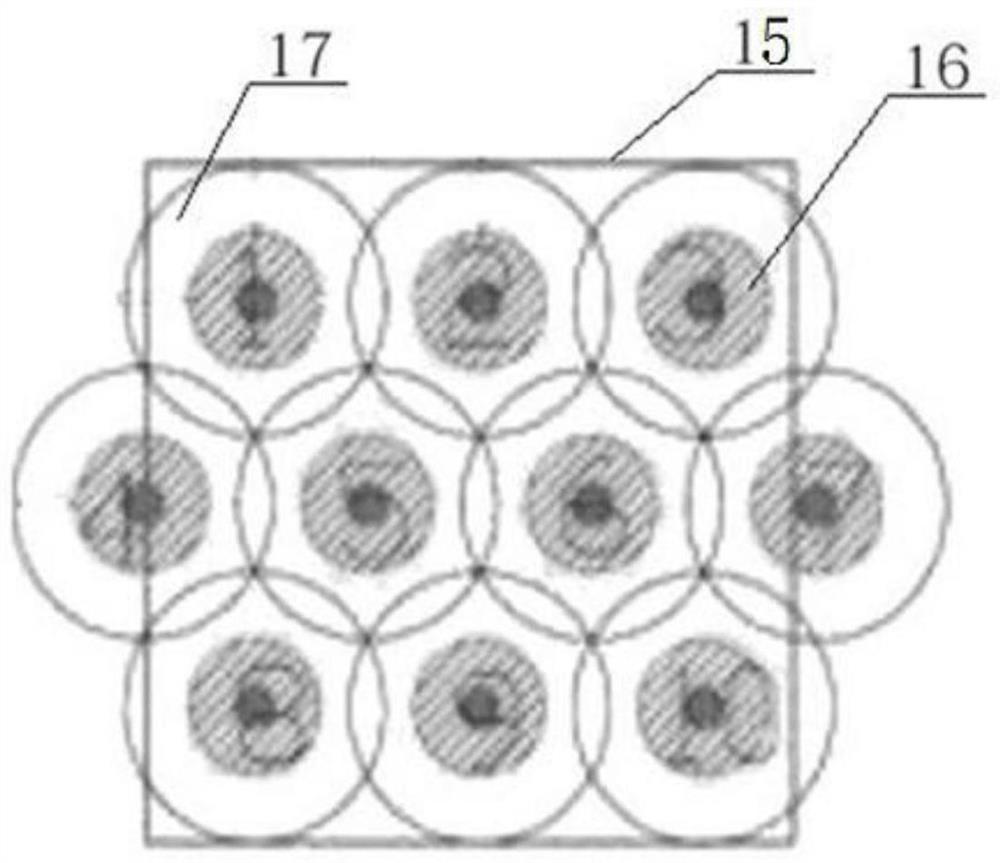

[0044] A. Select the plot to be processed, first level the site, and then mark the location of the drill holes, and set the offset between two adjacent rows of drill holes;

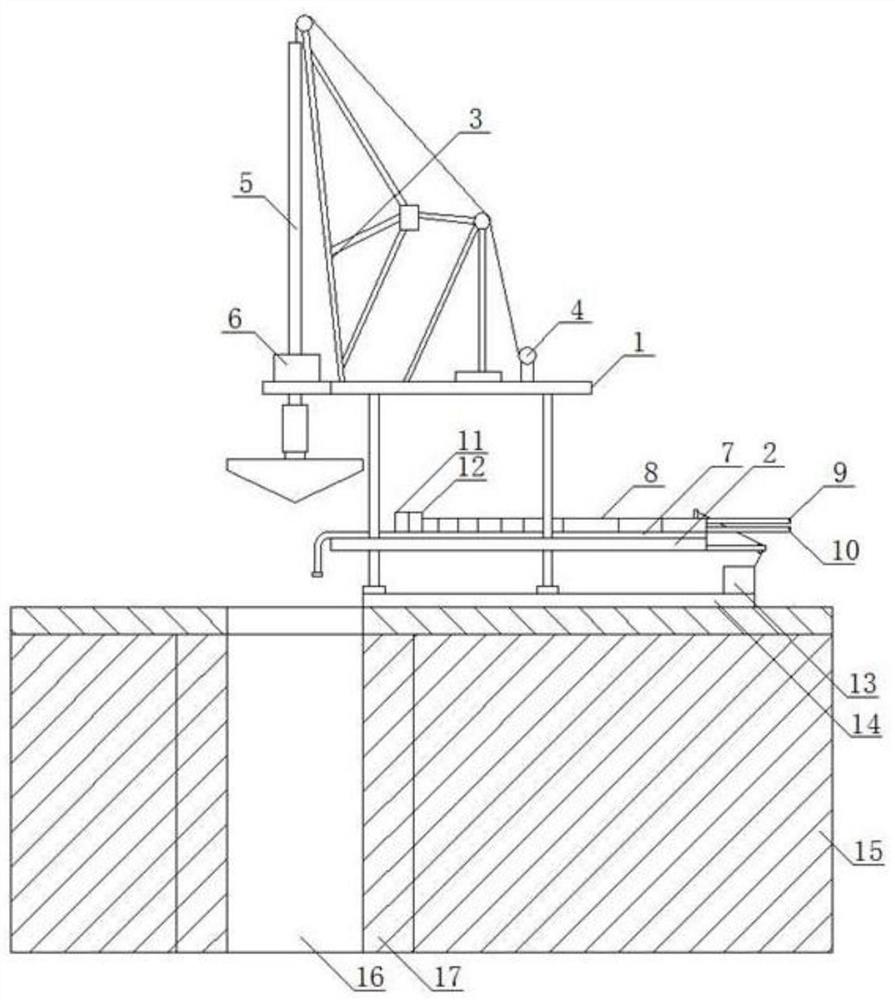

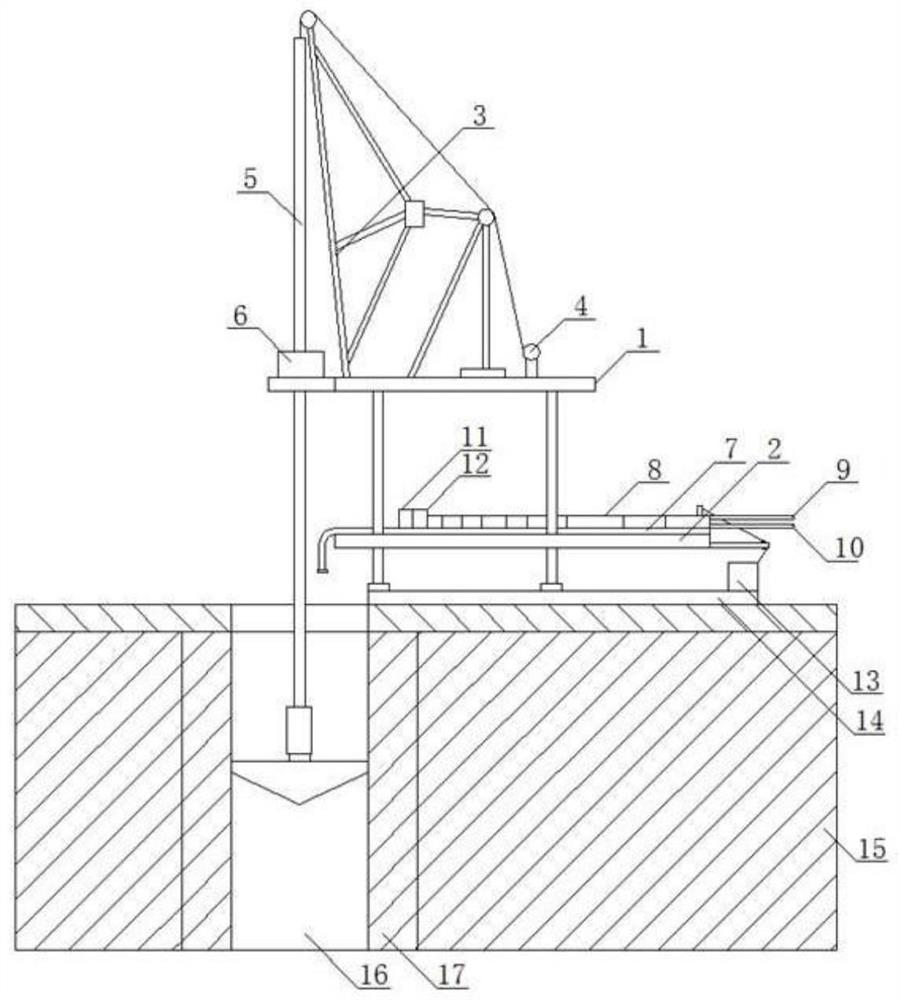

[0045] B. Use the drilling mechanism to guide the drilled hole, and the depth of the drilled hole is 2m;

[0046] C. Then gradually lift the repair liquid rotary nozzle from the bottom of the drill hole to the drill hole. During the lifting process, the repair liquid rotary nozzle sprays high-pressure repair agent flow around the drill hole, and at the same time, the compressed air rotary nozzle sprays compressed air. Stop the flow of high-pressure repair agent and compressed air when it reaches the hole;

[0047] D. Close the drill hole and let it stand until the repair agent reacts completely.

Embodiment 2

[0049] Soil high-pressure rotary spraying restoration process, including the following steps:

[0050] A. Select the plot to be processed, first level the site, and then mark the location of the drill holes, and set the offset between two adjacent rows of drill holes;

[0051] B. Use the drilling mechanism to conduct the drilling process for the drill hole, and the depth of the drilling hole is 10m;

[0052] C. Then gradually lift the repair liquid rotary nozzle from the bottom of the drill hole to the drill hole. During the lifting process, the repair liquid rotary nozzle sprays high-pressure repair agent flow around the drill hole, and at the same time, the compressed air rotary nozzle sprays compressed air. Stop the flow of high-pressure repair agent and compressed air when it reaches the hole;

[0053] D. Close the drill hole and let it stand until the repair agent reacts completely.

Embodiment 3

[0055] Soil high-pressure rotary spraying restoration process, including the following steps:

[0056] A. Select the plot to be processed, first level the site, and then mark the location of the drill holes, and set the offset between two adjacent rows of drill holes;

[0057] B. Use the drilling mechanism to guide the drilled hole, and the depth of the drilled hole is 6m;

[0058] C. Then gradually lift the repair liquid rotary nozzle from the bottom of the drill hole to the drill hole. During the lifting process, the repair liquid rotary nozzle sprays high-pressure repair agent flow around the drill hole, and at the same time, the compressed air rotary nozzle sprays compressed air. Stop the flow of high-pressure repair agent and compressed air when it reaches the hole;

[0059] D. Close the drill hole and let it stand until the repair agent reacts completely.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com