Linear stroke transmission device of electric valve actuator

A technology for electric valves and transmissions, which is applied in the field of transmissions and actuator transmissions. It can solve problems such as wear of internal threaded nuts, lower adjustment accuracy, and increased fit gaps, so as to improve fit accuracy, reduce wear, and improve wear resistance. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

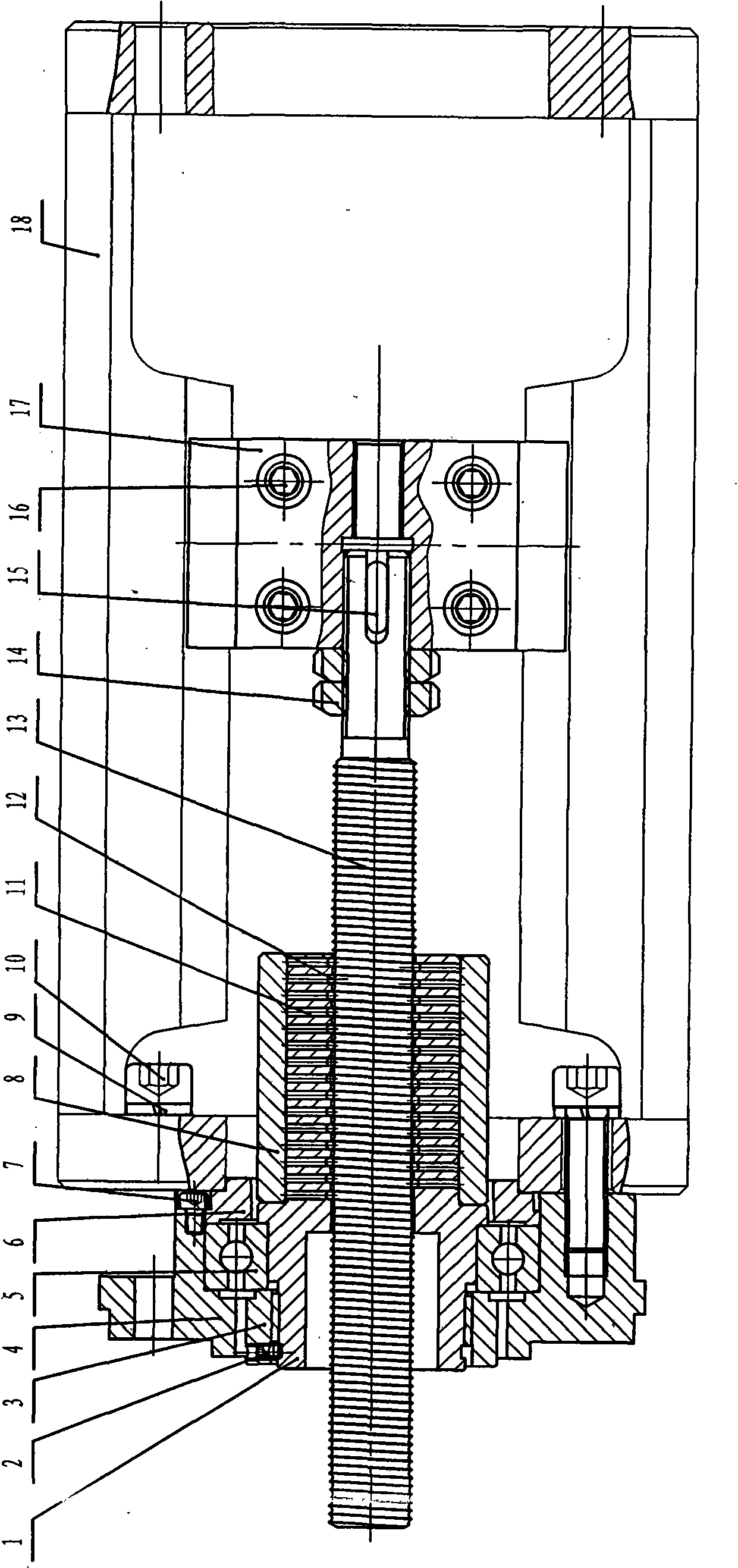

[0010] like figure 1 The straight stroke transmission device of the electric valve actuator shown includes a thrust base 4, a bracket 18, a drive bushing 1, and a push rod 13. The thrust base 4 is fixedly connected to the motor side of the electric valve actuator, and the drive bushing 1 It is fixedly connected with the output shaft on the motor side of the electric valve actuator, and one end of the push rod 13 is a screw rod, and the other end is fixedly connected with the valve stem of the regulated valve through the clamping plate 17 . Plywood 17 is made up of two splints fixedly installed by cylinder screw 16, and its two sides are embedded in the vertical groove of support 18, can linearly move in this vertical groove, and limit its circumferential direction rotation. Radially between the so-called other end of push rod 13 and clamping plate 17 is positioned by key 15, prevents that push rod 13 rotates in clamping plate 17, and axially is fixedly installed by nut 14. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com