Anti-water leakage heat exchange tube device and method for connecting and mounting same

A technology for heat exchange tubes and water leakage prevention, which is applied in the fluid circuit connection of heating devices, solar thermal devices, and solar collectors, etc., and can solve the problems of fragile glass vacuum heat collector tubes, high manufacturing costs, and large heat loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

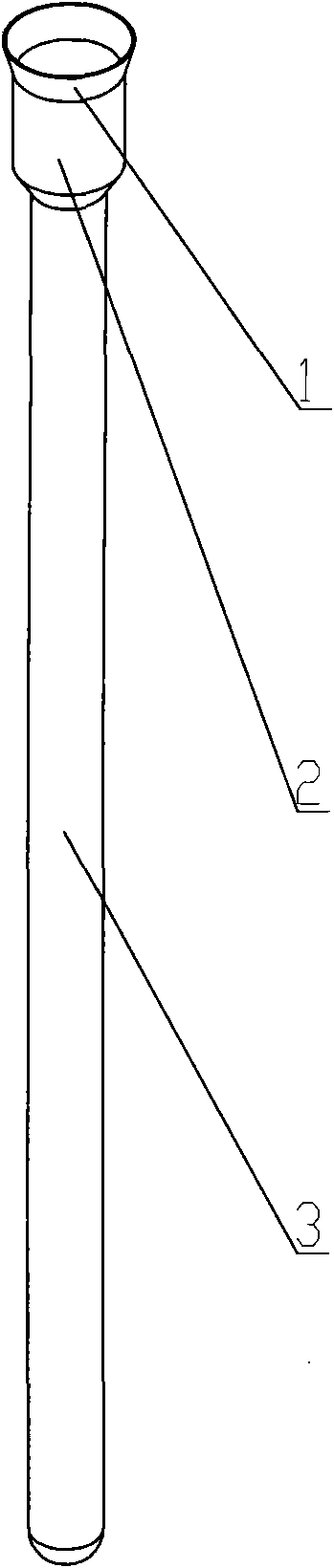

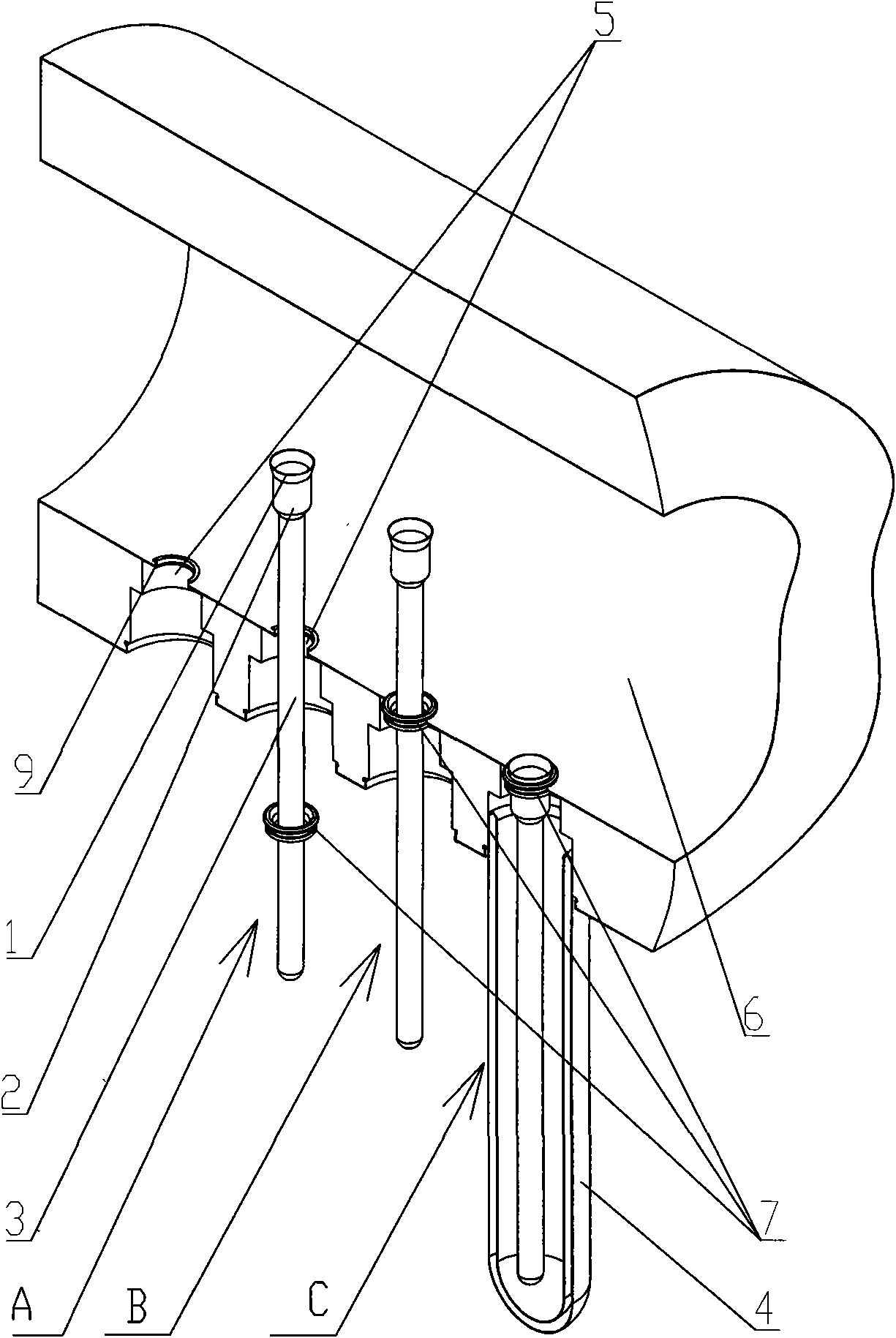

[0026] like figure 1 As shown, the anti-leakage water heat exchange tube device of the present invention is provided with a horn-shaped nozzle 1, a straight neck pipe joint 2 is connected under the horn-shaped nozzle 1, and a heat exchange pipe body with a blocked bottom is connected under the straight neck pipe joint 2 3.

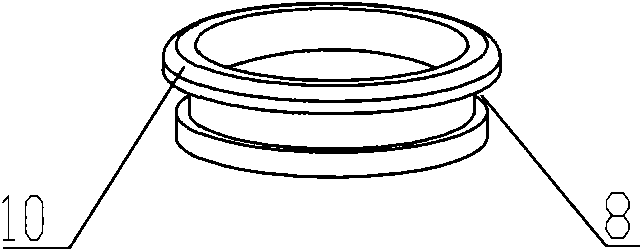

[0027] like figure 1 , figure 2 As shown, insert the trumpet-shaped nozzle 1 and the straight neck pipe joint 2 through the water tank connection port 5 into the water tank 6 of the solar water heating device, and then put the sealing ring 7 on the heat exchange pipe body 3 (see figure 2 Middle A), push it to the connection port 5 of the water tank, and then pull the leak-proof water heat exchange tube outward (see figure 2 Middle B).

[0028] like Figure 4 As shown, the anti-leakage water heat exchange tube device of the present invention is provided with a horn-shaped nozzle 1, a straight neck pipe joint 2 is connected under the horn-shaped nozz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com