Shell and manufacturing method thereof

A manufacturing method and shell technology, applied to chemical instruments and methods, electrical equipment shells/cabinets/drawers, decorative art, etc., can solve the problems of high ink consumption, complicated process, lack of realism, etc., to improve production efficiency, Easy to make effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

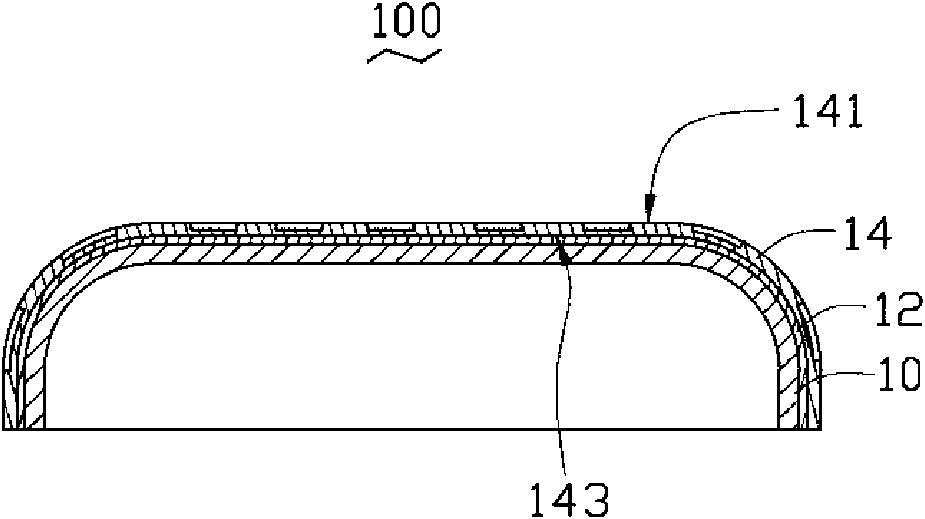

[0015] The casing 100 of the preferred embodiment of the present invention is as figure 1 As shown, it includes a film layer 14 , a decoration layer 12 disposed on the film layer 14 and a base layer 10 combined on the decoration layer 12 .

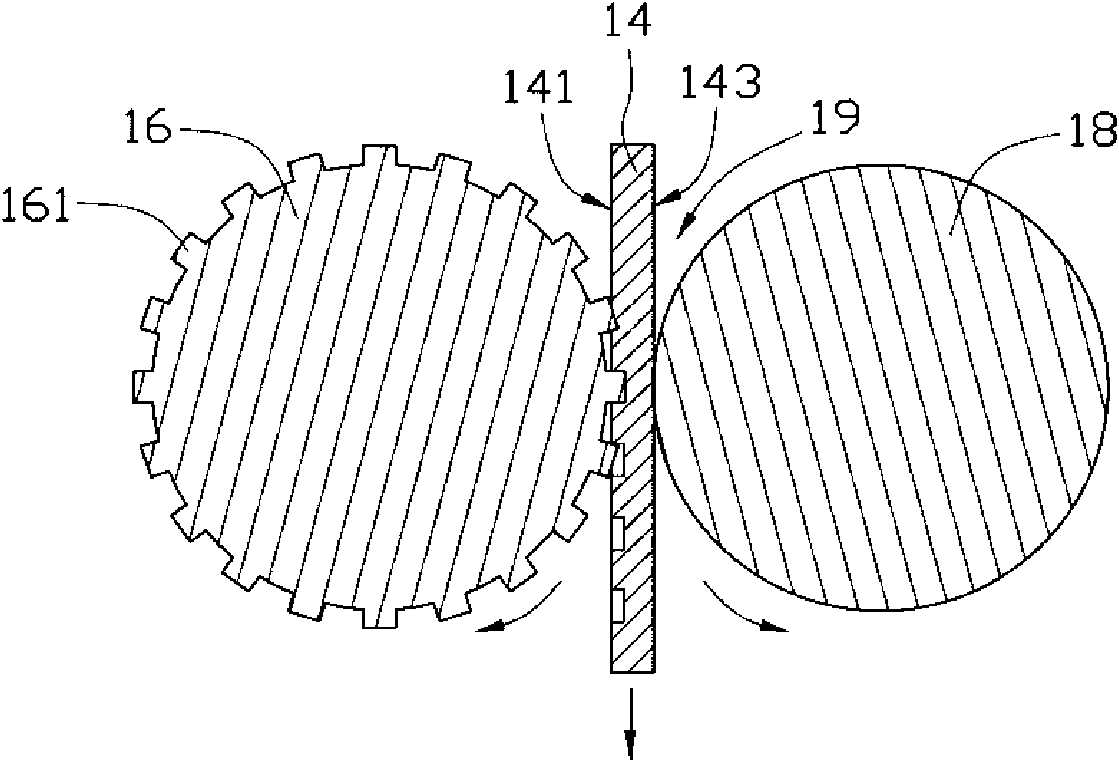

[0016] The film layer 14 is a plastic layer, which can be made by injection molding. The material forming the film layer 14 can be selected from any one of polycarbonate (PC), polyethylene terephthalate (PET), polymethyl methacrylate (PMMA) or polylactic acid (PLA). . The thin film layer 14 includes an outer surface 141 and an inner surface 143 opposite to the outer surface 141, and the outer surface 141 is formed with several geometric three-dimensional patterns, such as circular, square or other irregularly shaped grooves, Protrusions or other textures, the three-dimensional pattern on the outer surface 141 in this embodiment is a square groove. The inner surface 143 is flat.

[0017] The decoration layer 12 can be an ink layer, whic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com