Spark plug

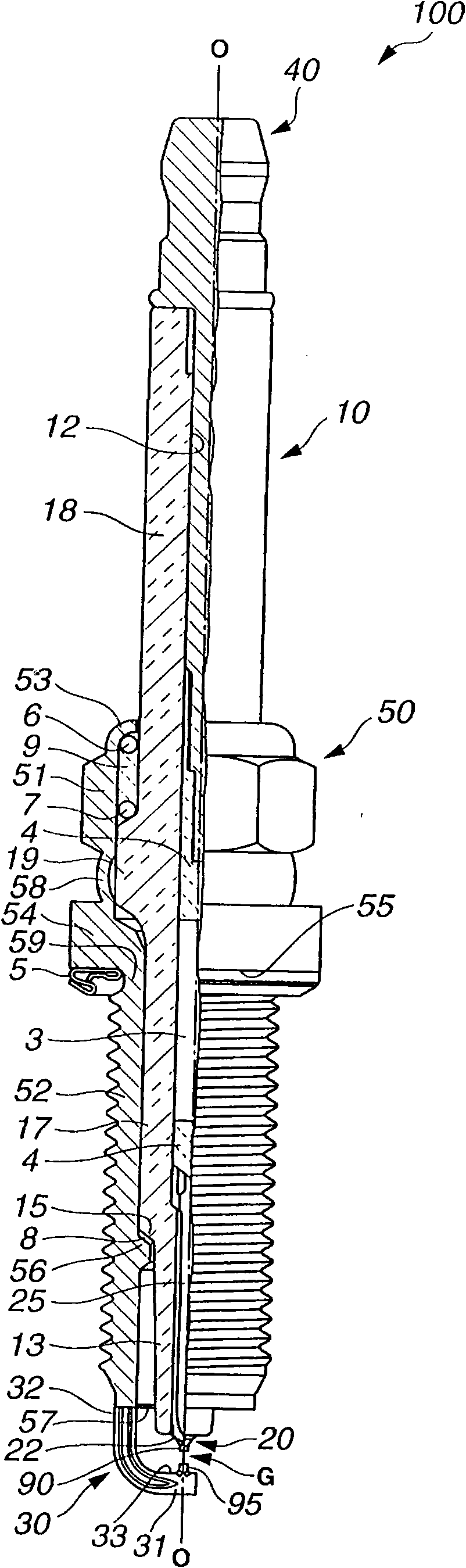

A spark plug and ground electrode technology, applied in the field of spark plugs, can solve the problems of ground electrode breakage resistance degradation, ground electrode heat dissipation reduction, internal stress breakage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

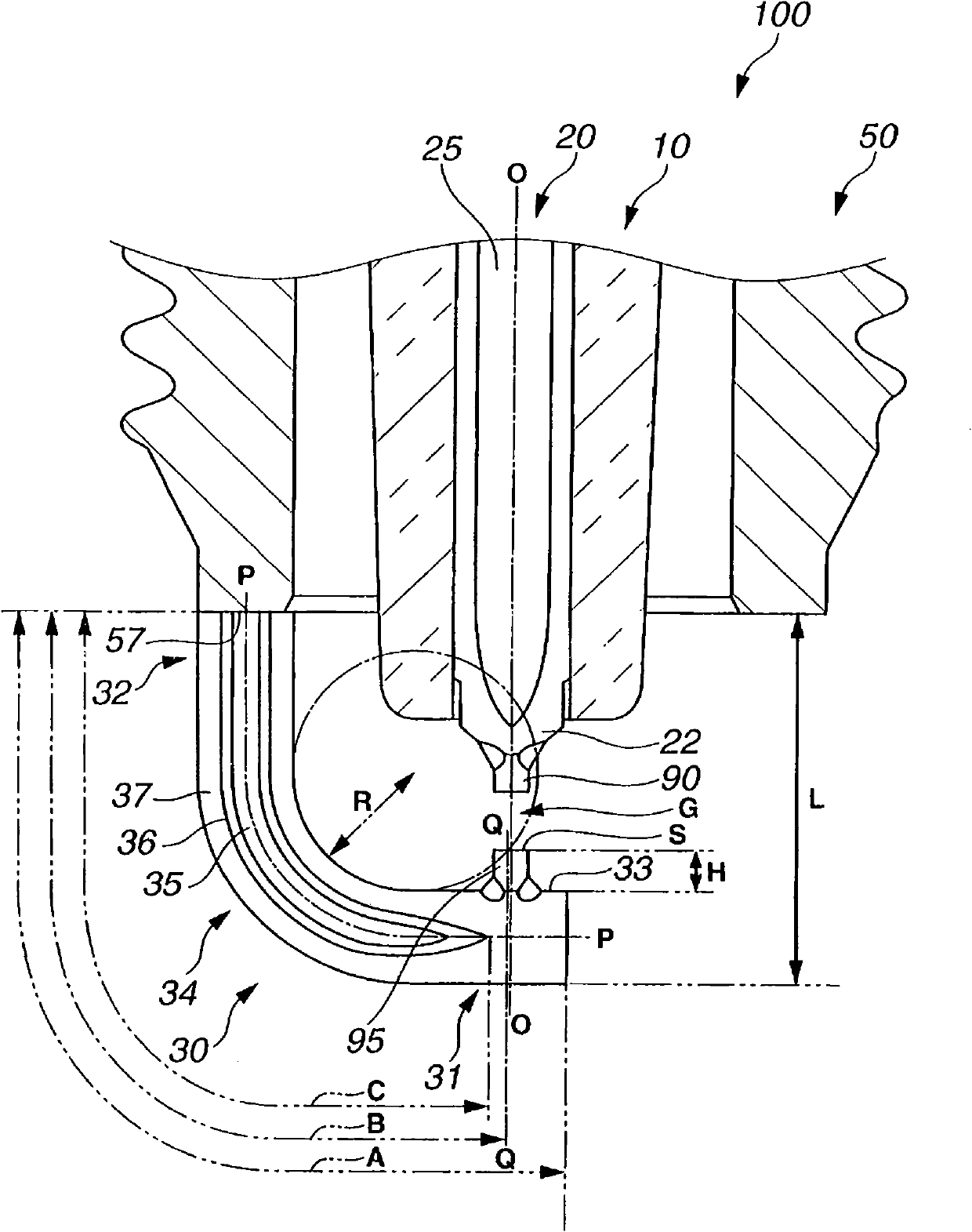

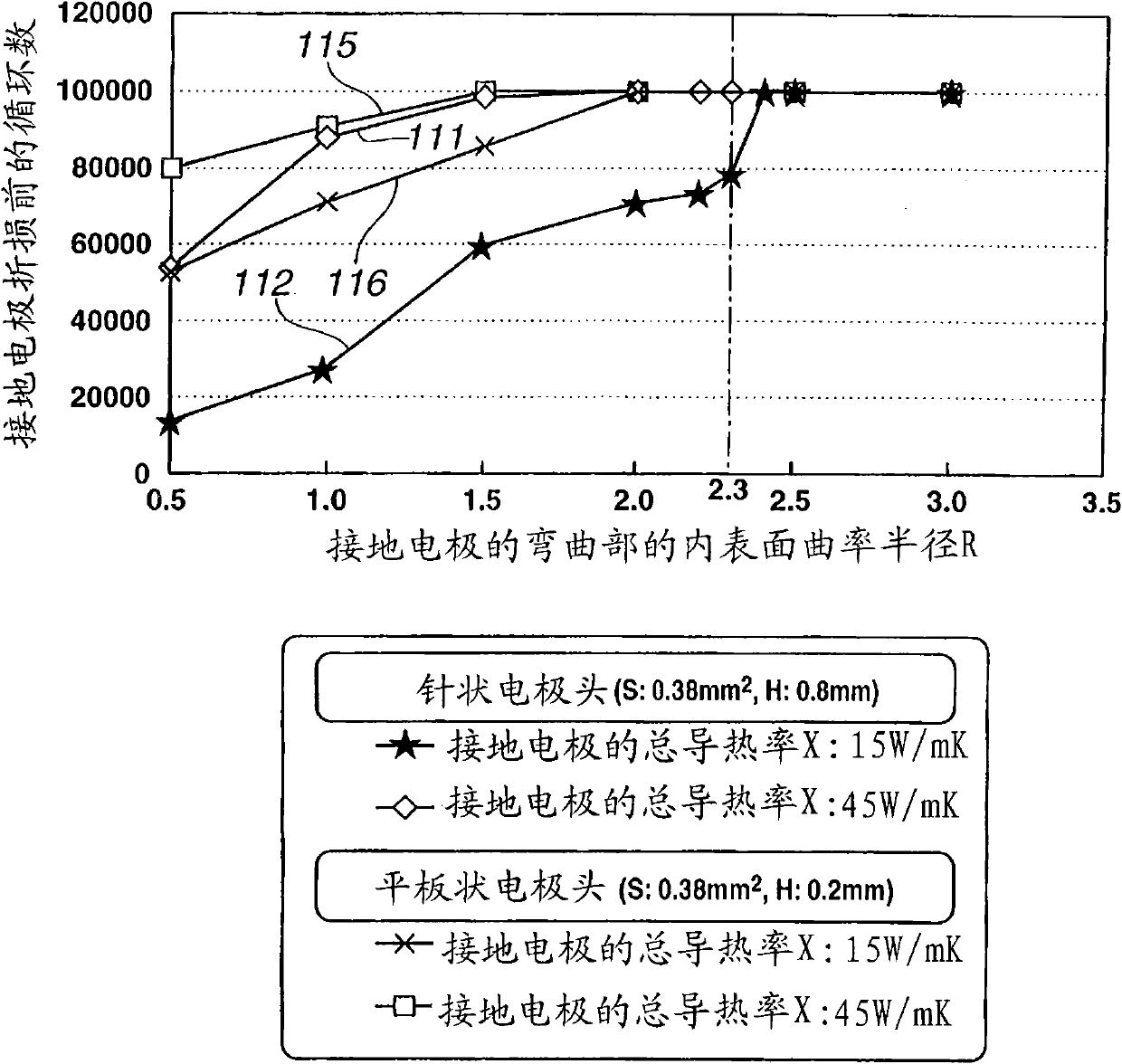

[0058] In Example 1, an evaluation test was performed to verify the relationship between the curvature of the bent portion 34 of the ground electrode 30 and the life of the ground electrode 30 . For this evaluation test, a plurality of ground electrodes each having a three-layer structure composed of first, second and third structural members and showing a value of 15 W / (m·K ) or a total thermal conductivity X of 45W / (m K). In addition, the preparation cross-sectional area S is 0.38mm 3 ( 0.7mm) and a needle-shaped electrode tip with a protruding length H of 0.8mm and a cross-sectional area S of 0.38mm 3 And the protruding length H is a plate-shaped electrode tip of 0.2 mm, and the needle-shaped electrode tip and the plate-shaped electrode tip are joined to two kinds of ground electrodes having the above-mentioned total thermal conductivity X. Spark plug samples were assembled using these grounded electrodes with tip. In each spark plug sample, the ground electrode was be...

Embodiment 2

[0063] In Example 2, an evaluation test was performed to verify the relationship between the total thermal conductivity X of the ground electrode 30 and the life of the ground electrode 30 . For this evaluation test, a plurality of ground electrodes each having a three-layer structure of first, second and third structural members as in the case of Example 1 and showing the Total thermal conductivity X in the range of 15W / (m·K) to 110W / (m·K). Here, three ground electrodes are prepared for each thermal conductivity level X. In addition, the preparation cross-sectional area S is 0.38mm 3 ( 0.7 mm) with a protruding length H of 0.8 mm and bonded to each ground electrode. Spark plug samples were completed by forming a bend in the ground electrode in such a manner as to control the radius of curvature R of the ground electrode's inner surface for each thermal conductivity level X to three different levels: 1.0 mm, 1.5 mm, and 2.0 mm. An evaluation test was performed by applying...

Embodiment 3

[0067] In Example 3, an evaluation test was performed to verify the relationship between the protruding length L of the ground electrode 30 from the front end face 57 of the metal shell 50 and the life of the ground electrode 30 . For this evaluation test, a plurality of ground electrodes each having a three-layer structure of first, second and third structural members as in the case of Example 1 and showing the Total thermal conductivity X of 15W / (m·K) or 45W / (m·K). These ground electrodes are cut to such an entire length that the ground electrodes are bent to form a bend with a radius of curvature R of 1.5 mm and the protruding length L of the ground electrodes is controlled within the range of 4.0 mm to 10.0 mm (see figure 2 ). The preparation cross-sectional area S is 0.38mm 3 A needle-shaped electrode tip with a protruding length H of 0.8 mm was used, and the prepared electrode tip was bonded to each ground electrode. Spark plug samples were completed using these tipp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com