Vehicular bumper system

A technology for bumpers and car bodies, applied in the field of bumper systems for car bodies, can solve problems such as increasing section thickness, and achieve the effect of ensuring characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] Hereinafter, embodiments of the present invention will be described below using the drawings and the like.

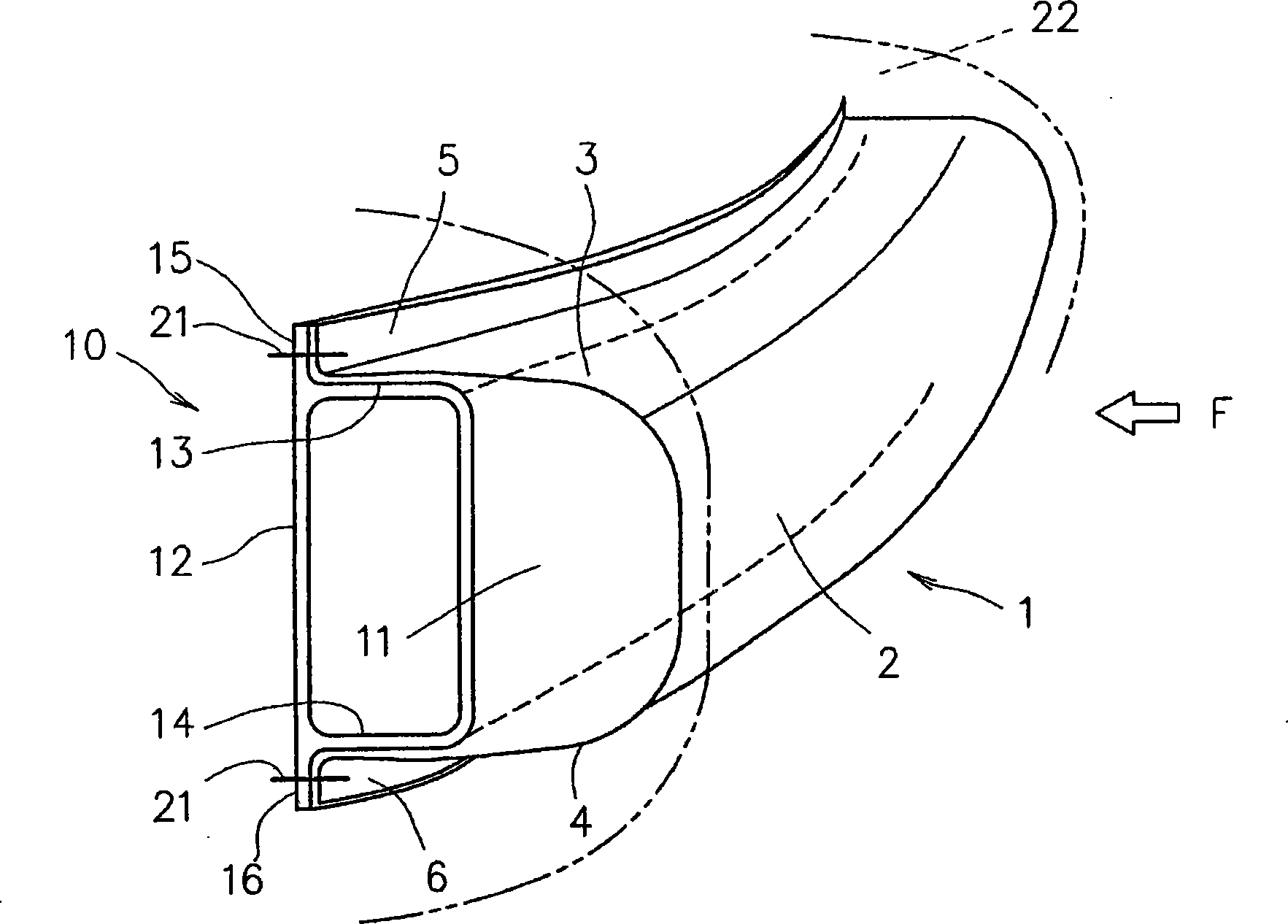

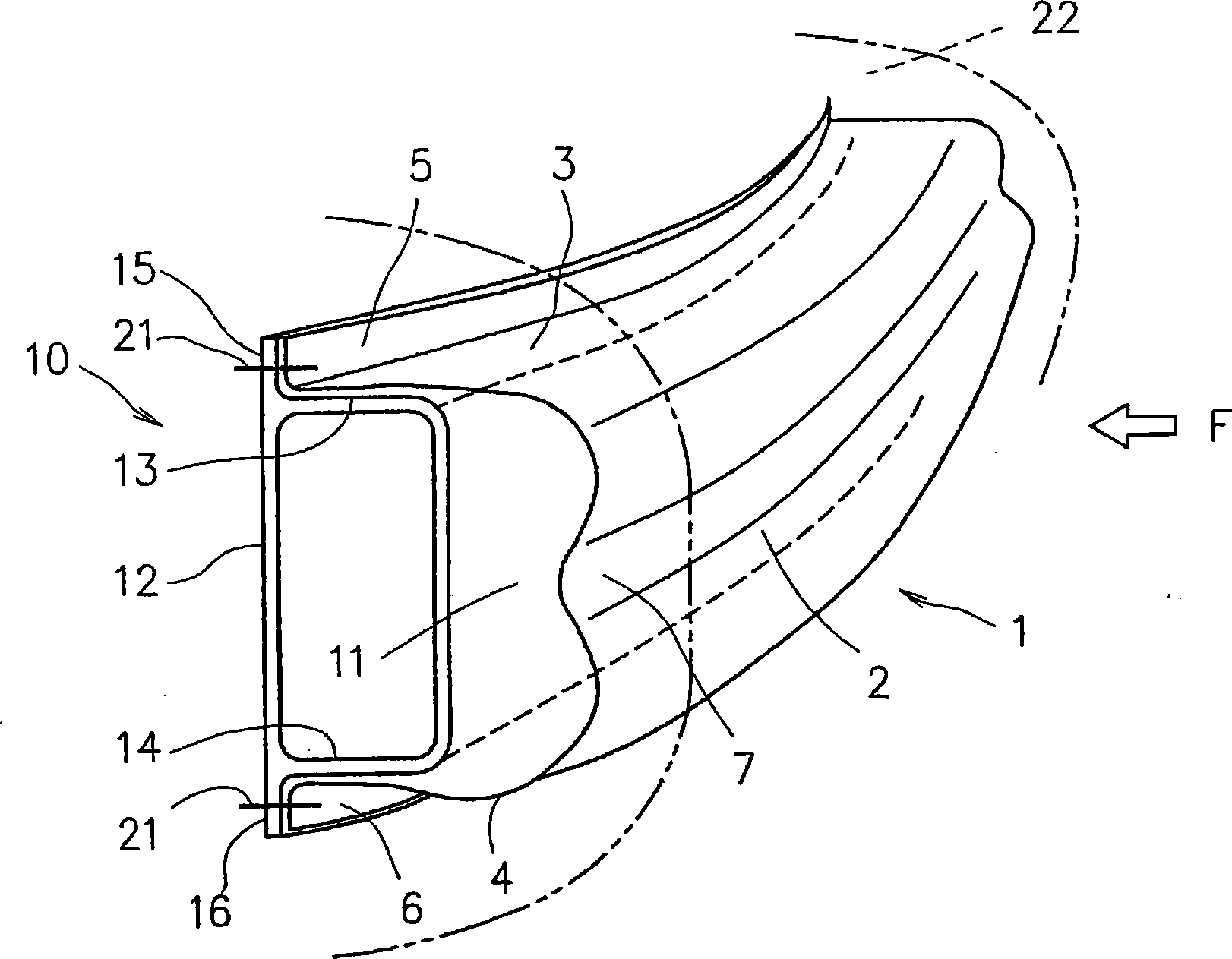

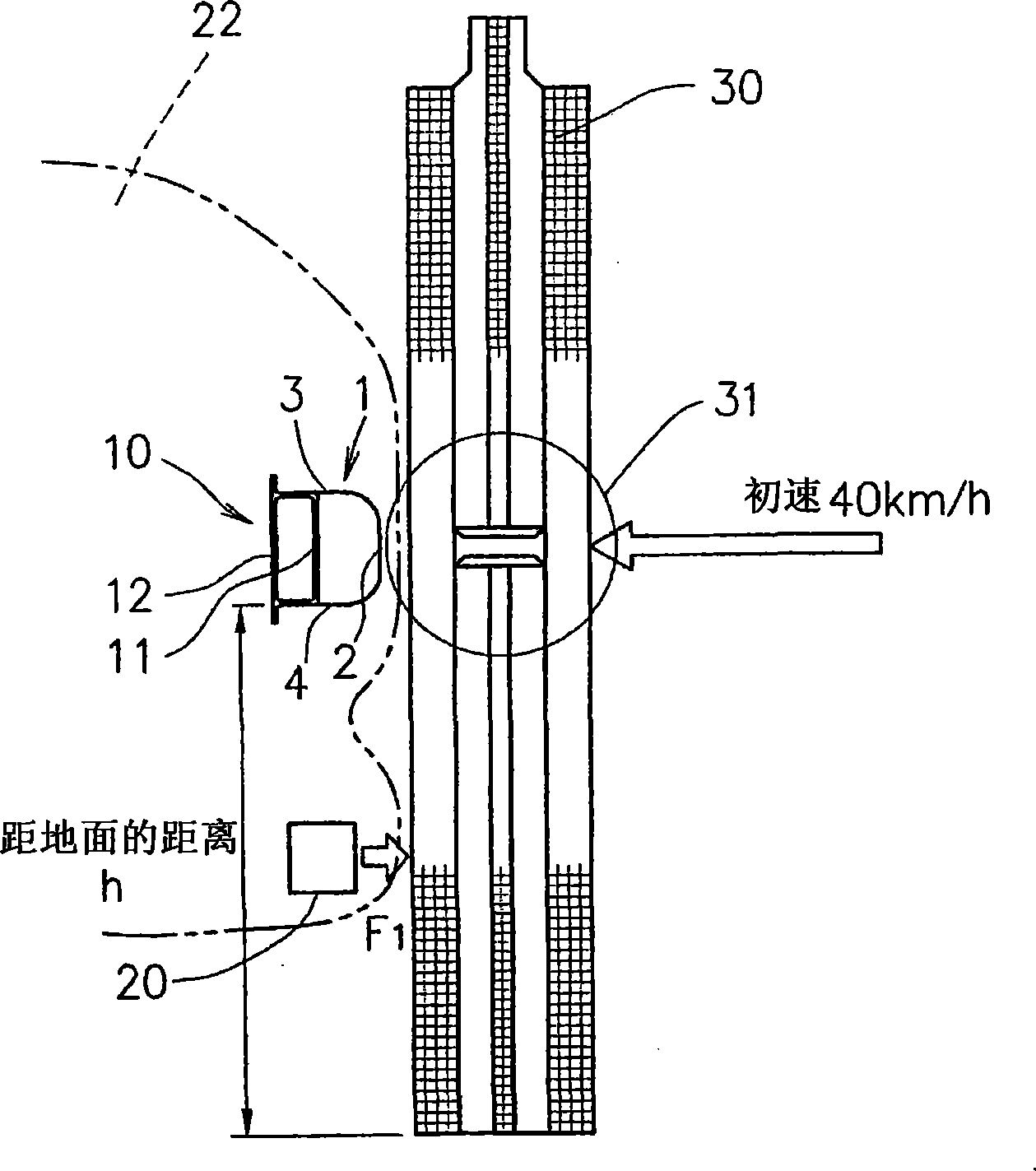

[0037] figure 1 It is a perspective view showing one form of the bumper system for a vehicle body of the present invention provided on the front side or rear side of the vehicle body, and showing a form in which a metal shock absorbing member is attached to the front side of the bumper beam. figure 2 It is a perspective view which only shows another form of the shock absorbing member attached.

[0038] figure 1 , 2 The metal shock absorbing member 1 of the present invention has, as a basic structure, a collision wall portion 2 on the front side of the vehicle body, side wall portions 3 (upper side in the drawing), and 4 (lower side in the drawing) on the upper and lower sides, and each The upper and lower joining flanges 5 (upper side in the figure) and 6 (lower side in the figure).

[0039] in addition, figure 1 , 2 The bumper beam 10 has a hollow (sect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com