Piston-type leak stop

A water leakage protection, piston-type technology, applied in the direction of pipes/pipe joints/fittings, mechanical equipment, pipe components, etc., can solve the problems of high production cost, short life, unstable reliability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

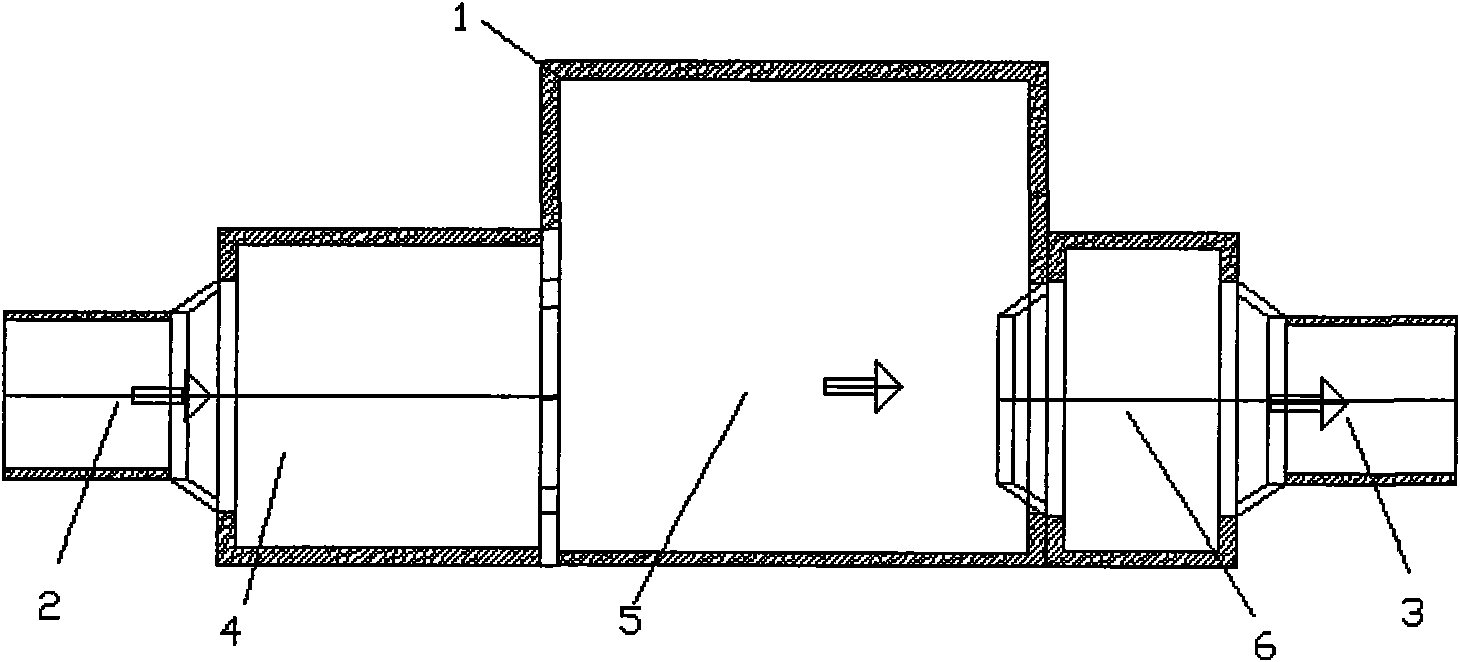

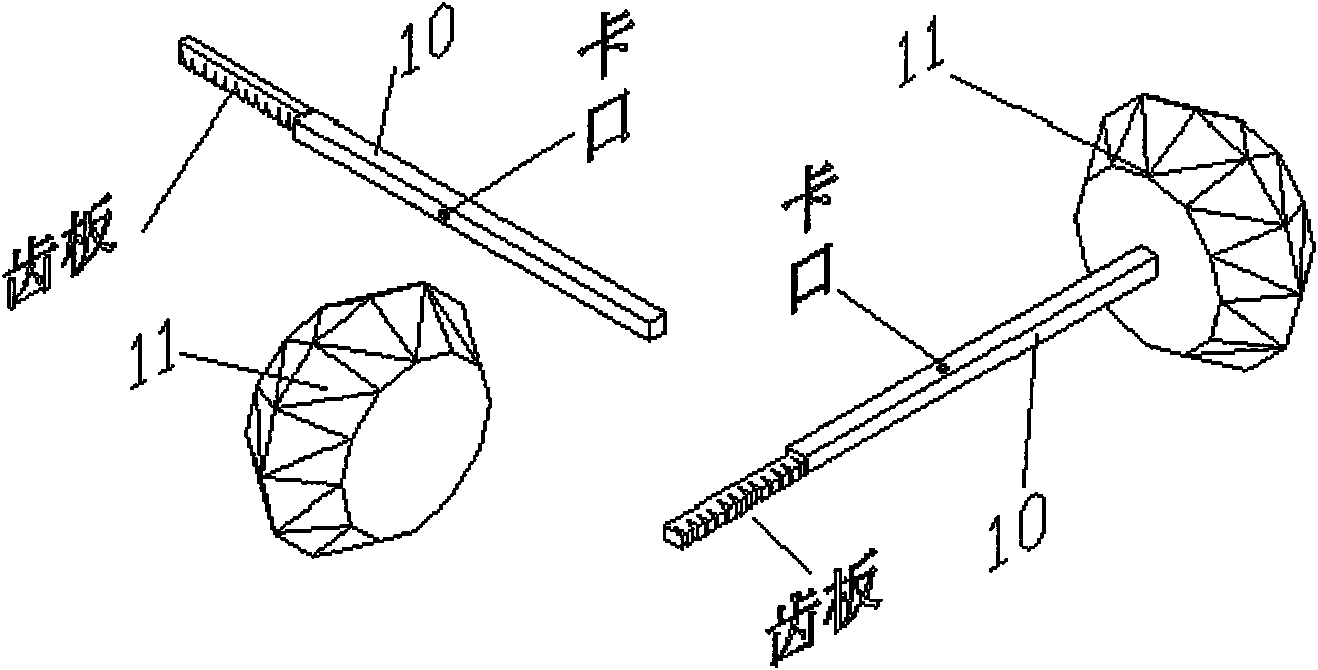

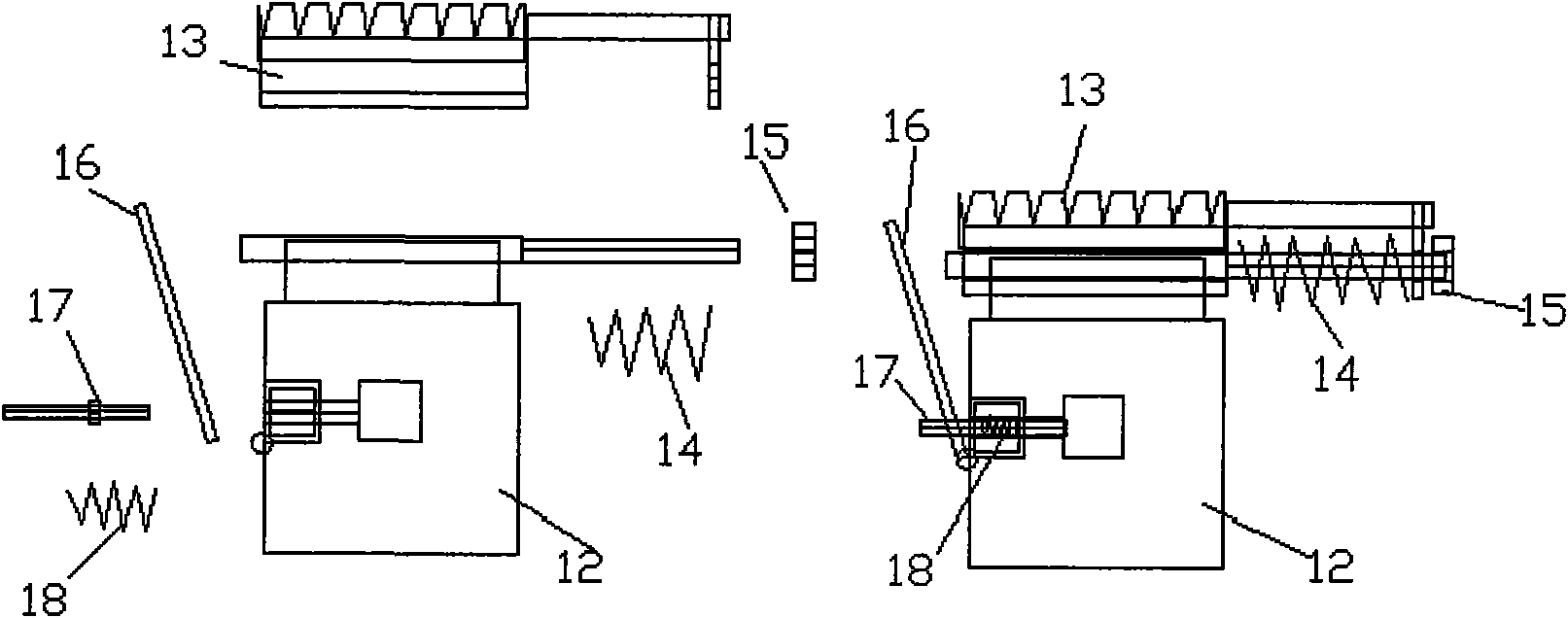

[0025] The piston type water leakage protector in the present embodiment is made up of casing (1), impeller, piston, movable base and reduction gear set. The impeller is set in the impeller chamber (4) of the casing (1), the transmission gear (9) on the impeller and the primary transmission gear (21) in the reduction gear set in the control chamber (5) of the casing (1) ) bite, when the impeller is installed, the direction of the impeller shaft (7) and the direction of the water inlet are on the same straight line (such as Figure 6 shown). The return spring (14) in the movable base is inserted into the rod of the base (12), then the tooth plate guide groove (13) is inserted into the guide rail on the base (12), and finally the nut (15) is screwed on, and the door seal in the piston The rod (10) and the two-way sealing door (11) are connected as a whole, and the sealing rod (10) is inserted into the return spring (19) and passed through the support (d), and then inserted into...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com