Wheel-rail vertical force continuous measurement method and device based on rail strain

A measurement method and vertical force technology, applied in the measurement of elastic deformation force by measuring gauges, etc., can solve problems such as the limitation of use range, and achieve the effect of simple implementation, accurate and effective data, and simple processing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

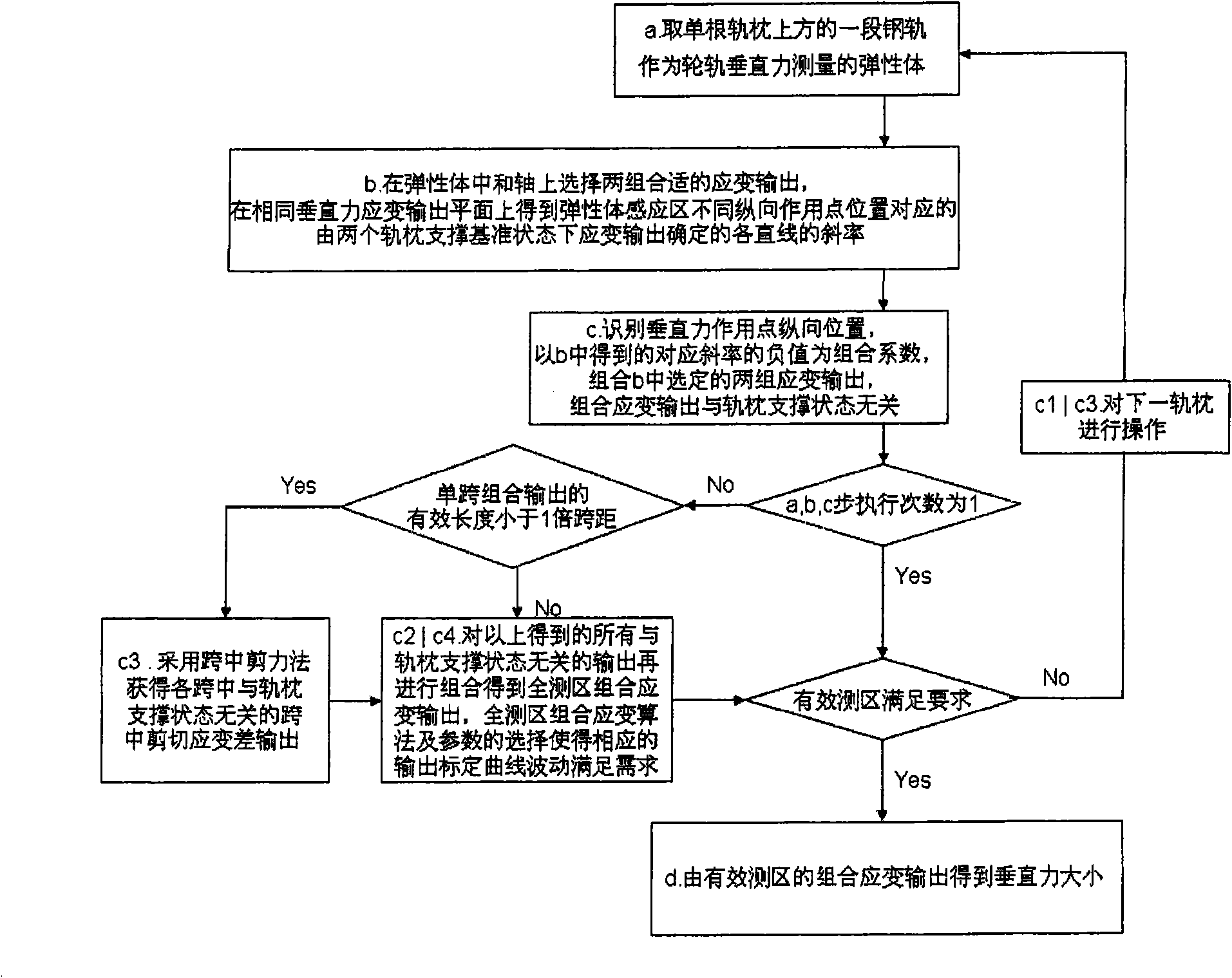

[0036] Such as figure 1 As shown, the present invention provides a continuous measurement method for wheel-rail vertical force based on rail strain. This embodiment aims to provide a stable measurement method for continuous wheel-rail vertical force in a short section where a train passes above a single sleeper, including the following step:

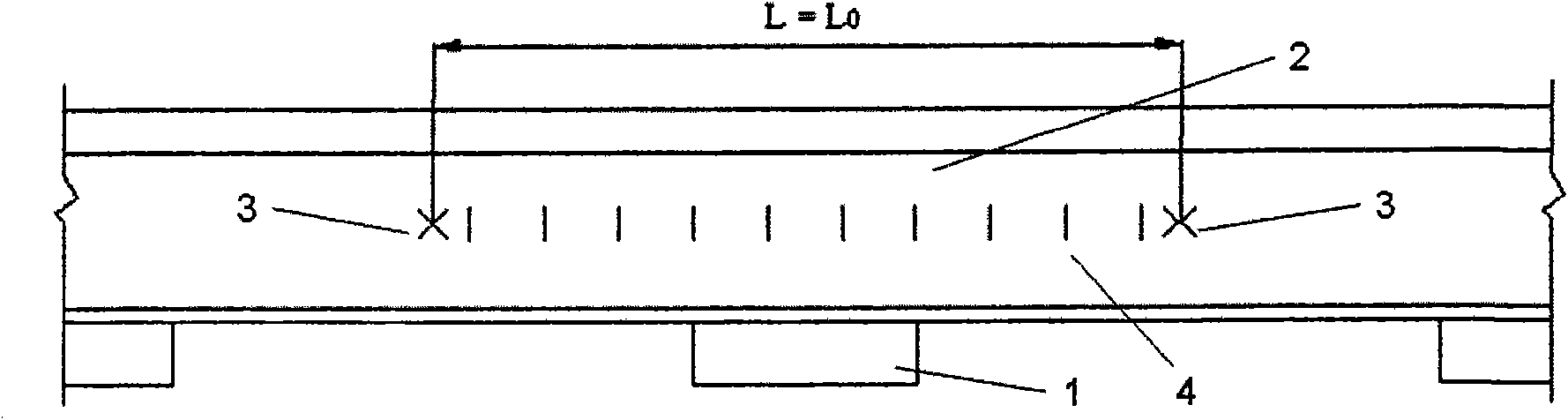

[0037] Step a: if figure 2 As shown, take a symmetrical steel rail above a single sleeper 1 as the elastic body 2 for measuring the vertical force of the wheel and rail. The length L of the elastic body 2 is usually not less than 2 times the length of the sleeper support and not greater than 2 times the span minus 2 times the sleeper support length, here the length L of the elastic body 2 is selected to be equal to a span L 0 .

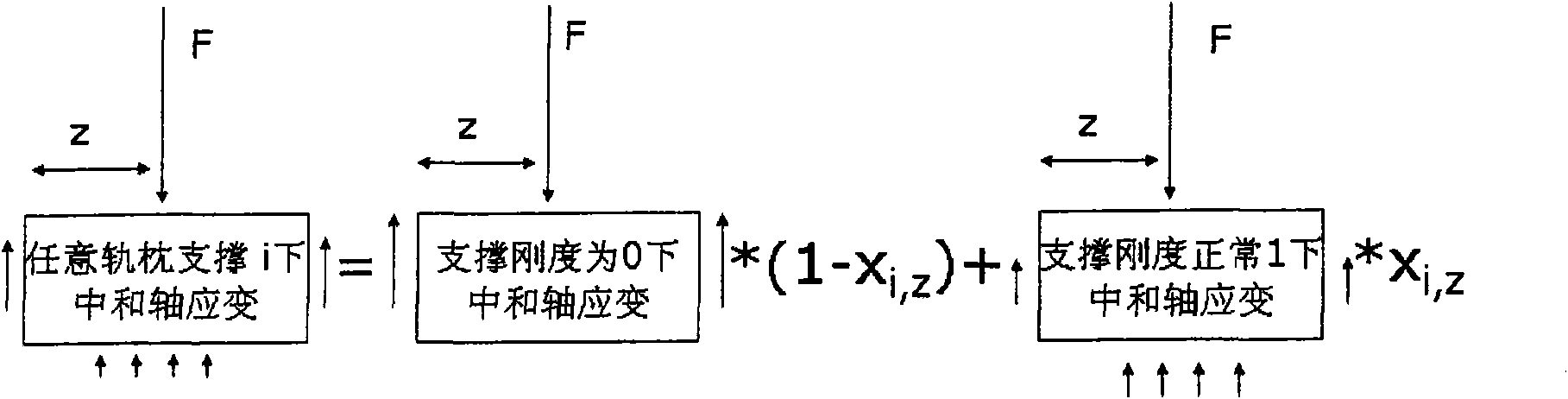

[0038] The research and the following data show that: a series of strains can be found on the neutral axis of the elastic body 2 (such as the shear strain difference between the two ends mentioned later and ...

Embodiment approach 2

[0061] Such as figure 1 As shown, the present invention provides a method for continuous measurement of wheel-rail vertical force based on rail strain. This embodiment aims to provide a stable, continuous measurement method for wheel-rail vertical force in a long measurement area, such as Figure 7-10 As shown, this implementation mode is based on implementation mode 1, and implementation mode 1 only executes steps a, b, and c once, and implementation mode 2 is based on implementation mode 1:

[0062] In step d, if the length of the effective measurement area does not meet the length requirements of the measurement section, and the obtained combined strain output on the rail above the single sleeper 1 results in an effective measurement area length not less than 1 times the span, then in Also include steps between steps c and d:

[0063]c1. Repeat steps a, b, and c along the rails until the length of the measurement section is met, and obtain the single-span combined strain o...

Embodiment approach 3

[0073] Such as figure 1 As shown, the present invention provides a method for continuous measurement of wheel-rail vertical force based on rail strain. Like Embodiment 2, this embodiment aims to provide a stable, continuous measurement method for wheel-rail vertical force in a long measurement area. 2. The difference is that the effective measurement area of the single-span combined strain output in Embodiment 3 (as described in Embodiment 1, here is the single-span effective measurement area with reduced requirements) is less than 1 times the span (generally corresponding to the elastic body 2 The length L is less than one span L 0 ), and the traditional mid-span vertical force measurement is carried out between the two spans, such as Figure 11 shown.

[0074] Embodiment 3 is based on Embodiment 1. Embodiment 1 only executes steps a, b, and c once. This embodiment is based on Embodiment 1:

[0075] In step d, if the length of the effective measurement area does not meet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com