Low-carbon Al2O3-C sliding material compounded by metal Si/Al and preparation method thereof

An al2o3-c, metal technology, applied in metal processing equipment, manufacturing tools, casting equipment, etc., can solve problems affecting service life, roughening, etc., and achieve energy saving, good oxidation resistance, and low carbon content.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

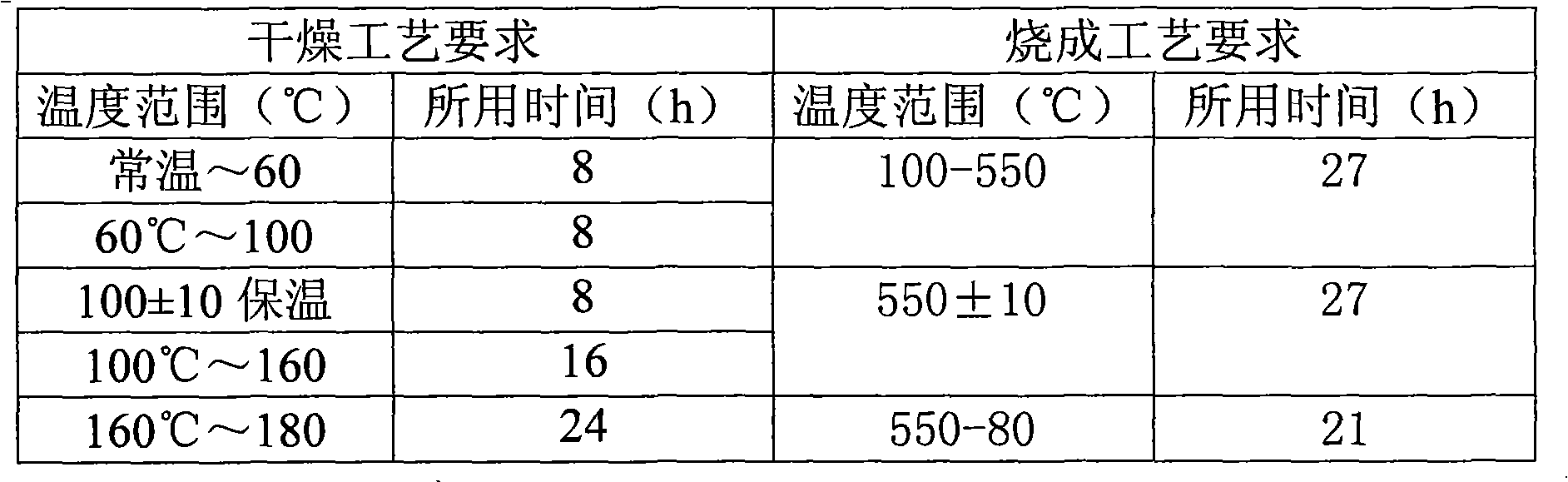

Embodiment 1

[0053] 1) Stir and mix 5 kg of metal Si powder with fineness ≤ 0.038mm and Si content ≥ 98%, and 4 kg of metal Al powder with fineness ≤ 0.088mm and Al content ≥ 98% to form metal Si and Al composite powder , and then select 20 kilograms of tabular corundum fine powder with a specification of less than or equal to 50 microns, 3 kilograms of activated alumina fine powder with a specification of less than or equal to 28 microns, and 3 kilograms of graphite with a fineness of ≤0.038mm and a C content of ≥98%, 2 kg of carbon black with fineness ≤ 0.01mm and C content ≥ 98.5%, 1 kg of B 4 C≥92% boron carbide fine powder, then add metal Si and Al composite powder mixed in advance, and mix in a double-cone mixer to form a mixed powder;

[0054] 2) Take 15 kilograms of 3-2 mm tabular alumina particles, 18 kg of 2-1 mm tabular alumina particles, 16 kg of 1-0.5 mm tabular alumina particles, and 13 kg of 0.5 mm or less tabular corundum particles, and stir and mix them. Take another 4 kg...

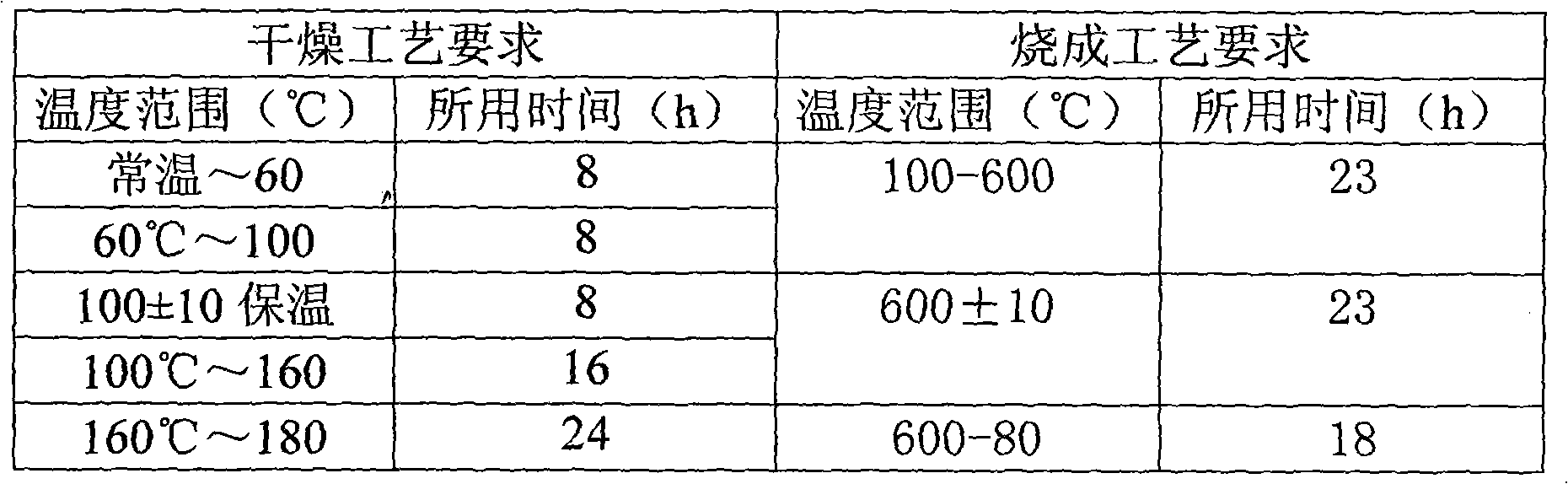

Embodiment 2

[0058] 1) 10 kg of metal Si powder with a fineness of ≤0.038mm and a Si content of ≥98%, and 2 kg of metal Al powder with a fineness of ≤0.088mm and an Al content of ≥98%, were stirred and mixed in advance to form metal Si and Al composite powder , and then select 18 kilograms of tabular corundum fine powder with a specification of less than or equal to 50 microns, 5 kilograms of activated alumina fine powder with a specification of less than or equal to 28 microns, 1 kilogram of graphite with a fineness of ≤0.038mm and a C content of ≥98%, 3 kilograms Carbon black with fineness≤0.01mm and C content≥98.5%, 1kg B 4 C≥92% boron carbide fine powder, then add metal Si and Al composite powder mixed in advance, and mix in a double-cone mixer to form a mixed powder;

[0059] 2) Take 15 kilograms of 3-2 mm tabular alumina particles, 18 kg of 2-1 mm tabular alumina particles, 13 kg of 1-0.5 mm tabular alumina particles, and 14 kg of 0.5 mm or less tabular corundum particles, and stir a...

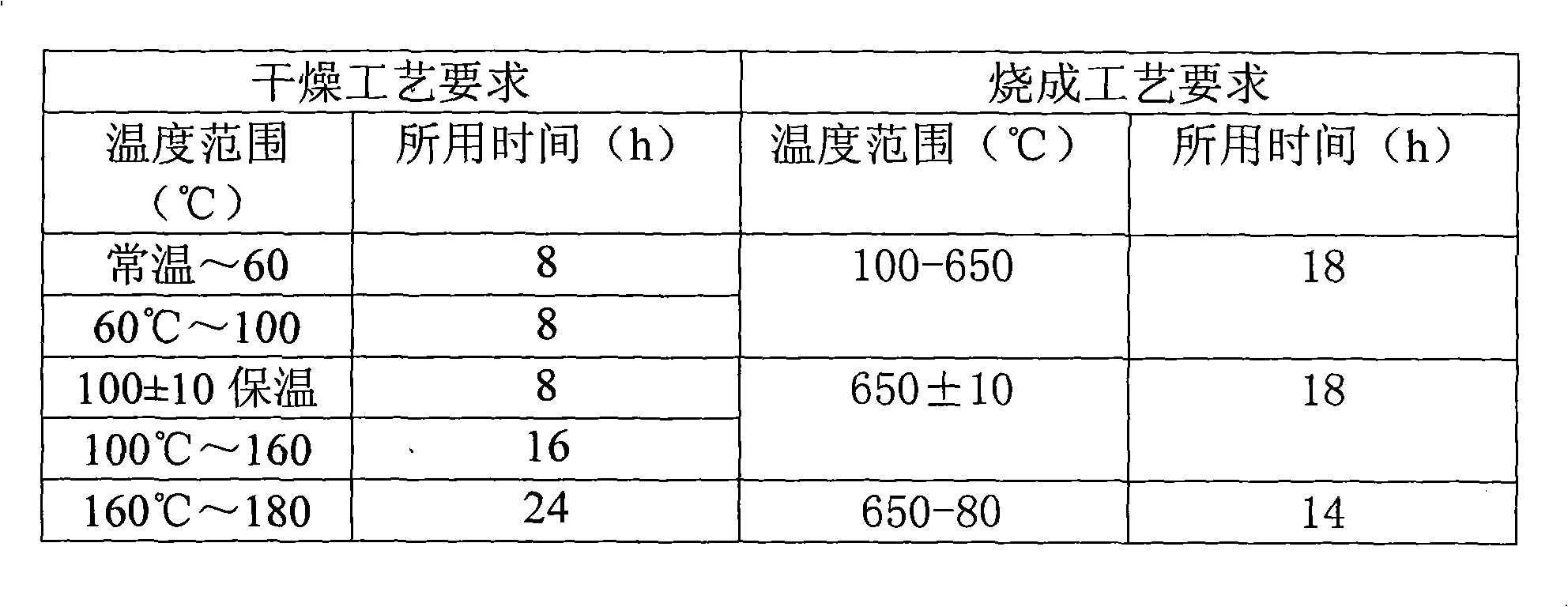

Embodiment 3

[0063] 1) 6 kg of metal Si powder with a fineness of ≤0.038mm and a Si content of ≥98%, and 1 kg of metal Al powder with a fineness of ≤0.088mm and an Al content of ≥98%, were stirred and mixed in advance to form metal Si and Al composite powder , and then select 18 kg of tabular corundum fine powder with a specification of less than or equal to 50 microns, 5 kg of activated alumina fine powder with a specification of less than or equal to 28 microns, 1 kg of graphite with a fineness of ≤0.038mm and a C content of ≥98%, 1 kg Carbon black with fineness ≤ 0.01mm and C content ≥ 98.5%, 2 kg of β-SiAlON fine powder with fineness ≤ 0.044 mm, 1 kg of B 4 C≥92% boron carbide fine powder, then add metal Si and Al composite powder mixed in advance, and mix in a double-cone mixer to form a mixed powder;

[0064] 2) Take 15 kg of 3-2mm tabular alumina particles, 20 kg of 2-1mm tabular alumina particles, 17 kg of 1-0.5mm tabular corundum particles, and 13 kg of tabular corundum particles ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com